Automotive

In the automotive industry, not only the shift from engines to motors as power sources but also the introduction of new technologies such as connectivity with the internet, autonomous driving, and electrification have created new demands in parts manufacturing.

In order to meet this demand, the construction of high-precision and flexible production systems is crucial. Mazak contributes to the high-precision machining of automotive parts with a wide range of lineup and machining technologies, offering turnkey solutions that support the introduction and operation of automation systems. Furthermore, we provide solutions that address cost reduction per part and minimize the impact on the global environment.

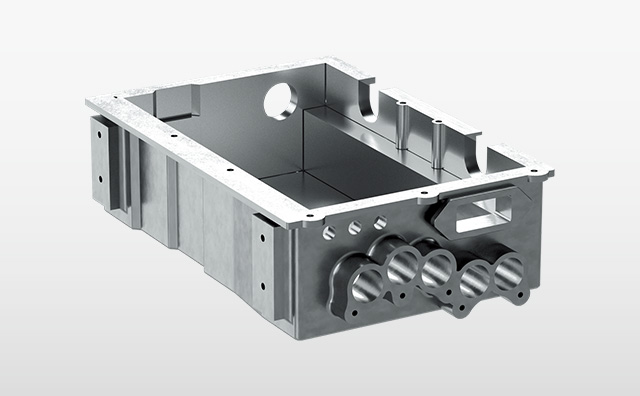

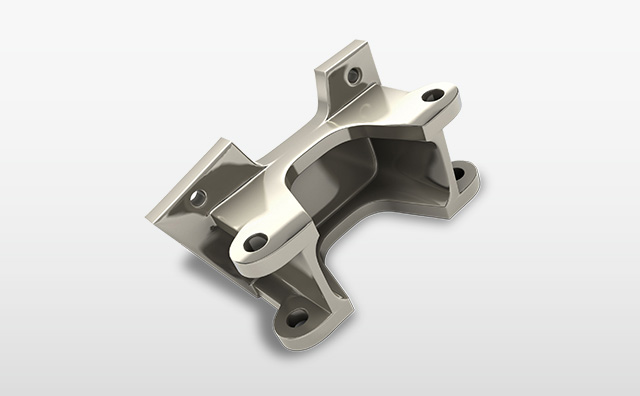

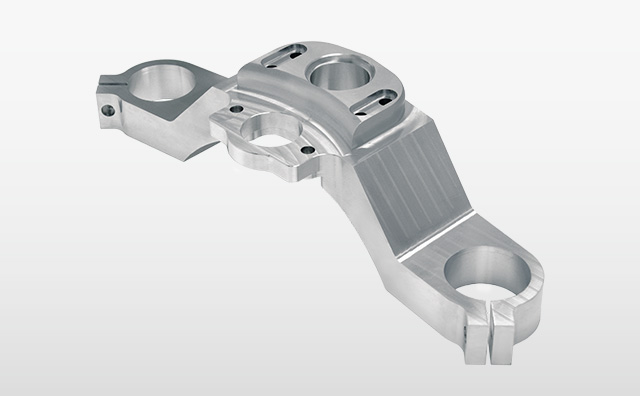

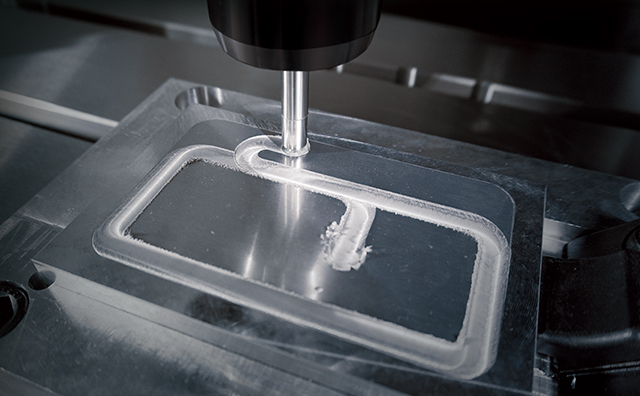

Examples of automotive parts

Mazak's machine tools enable the reduction of cycle time and achieve high-precision machining and improved productivity, even in parts manufacturing with complex shapes and various materials.

Solutions for EV

FSW (Friction Stir Welding)

In module components that make up motors, batteries, and other systems, welding technologies are required to integrate the parts together. Mazak has developed the FSW-460V, which is equipped with FSW (Friction Stir Welding) technology, which softens materials through friction heat to enable fast and stable welding. We propose a total solution from prototyping to mass production.

Gear Machining

The INTEGREX AG series features gear skiving, hobbing, and end milling functions, as well as gear measurement capabilities. By consolidating the gear processing steps, it enables shortened production lead time and high-precision machining. Furthermore, it also leads to cost reduction.

Mazak machines for various automotive parts manufacturing

Lineup of base machines for mass production parts machining

FF Series

High-speed, horizontal machining centers suitable for mass-production

Space-saving design, suitable for automation of machining lines

UN Series

Compact vertical/horizontal machining centers for large volume production

Narrow machine construction ideal for line construction that increases productivity per unit area

MULTIPLEX W Series

Symmetrical machine design with 2 spindles and 2 turrets

By placing spindles and tool turrets with the same capabilities on both sides, this machine has the capacity equivalent to two CNC lathes

HQR Series

High-efficiency 2 spindle / 2 turret multi-tasking CNC turning centers

The machine structure with upper and lower turrets and spindles on both sides significantly reduces cycle times

DUAL TURN 200

Twin spindle CNC turning centers

Integration of two 2-axis CNC turning centers into a single machine tool, performing continuous machining of the first and second process

Machining centers and turning centers for line production and automation of mass production parts machining

HCN NEO Series

High-speed, high-precision horizontal machining centers

The high-performance NEO series with high productivity and low environmental impact technologies

MEGA TURN Series

Vertical CNC turning centers

High-efficiency machining of large cylindrical parts, and flexible configuration of two machines with standard and mirror-image models

VC-PRIMOS Series

Space-saving high-performance vertical machining centers

Compact BT30 spindle is ideal for machining small parts for automotive mass production

QT-PRIMOS Series

Space-saving and high-production CNC turning centers

Excellent functionality and operability that can make effective use of the limited space at the machining site

FF-5000/40 GANTRY LOADER

Production line dedicated to processing engine parts with double arm gantry loader

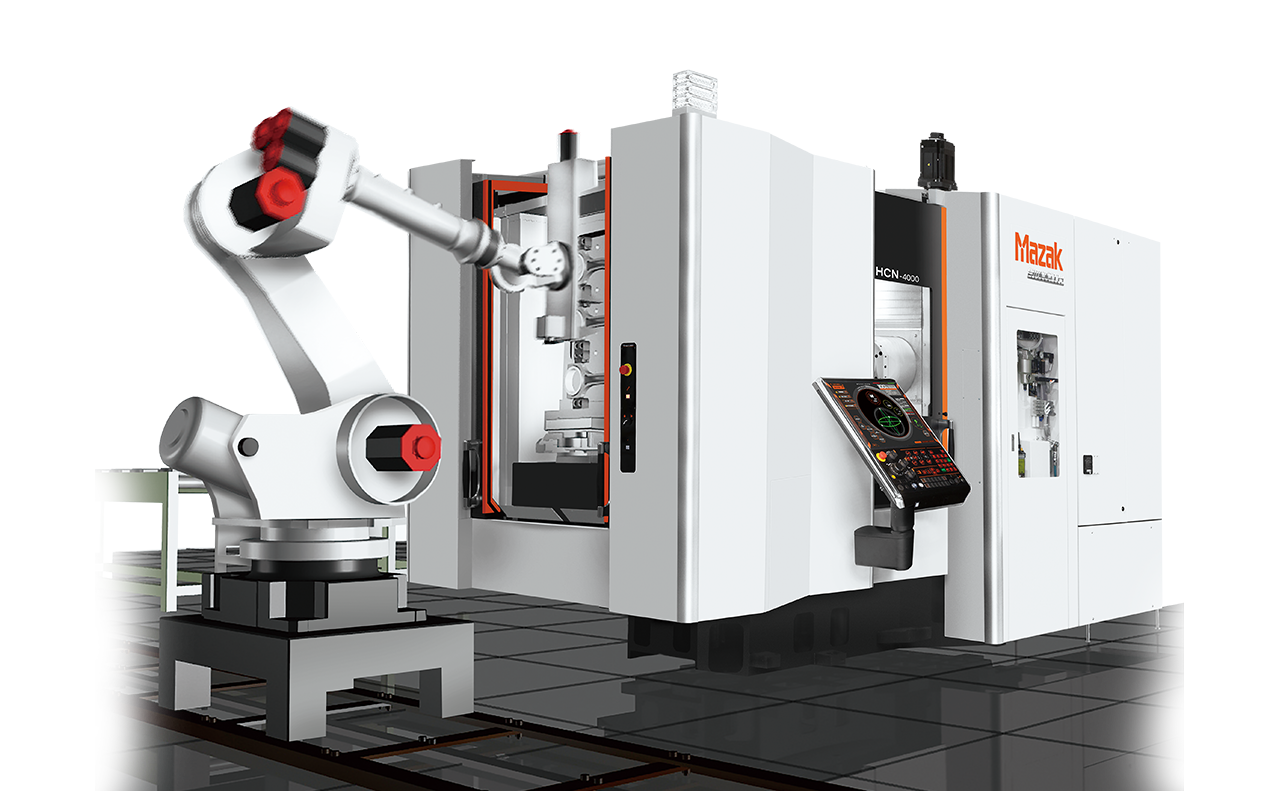

HCN-4000 ROBOT SYSTEM

Building a production system and line for engine parts processing through collaboration with articulated robots

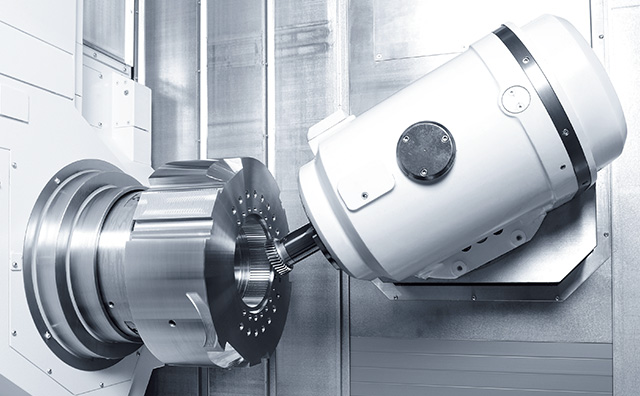

5-axis, multi-tasking machining centers ideal for prototype production

INTEGREX i-H Series

Simultaneous 5-axis horizontal multi-tasking machine

From turning to 5-axis machining using the Y-axis and B-axis, this machine can handle multiple processes

INTEGREX j Series

Horizontal multi-tasking machines for multi-face machining

Equipped with a 5 degree indexing milling spindle that can perform outer diameter, end face, and angled machining with a single tool

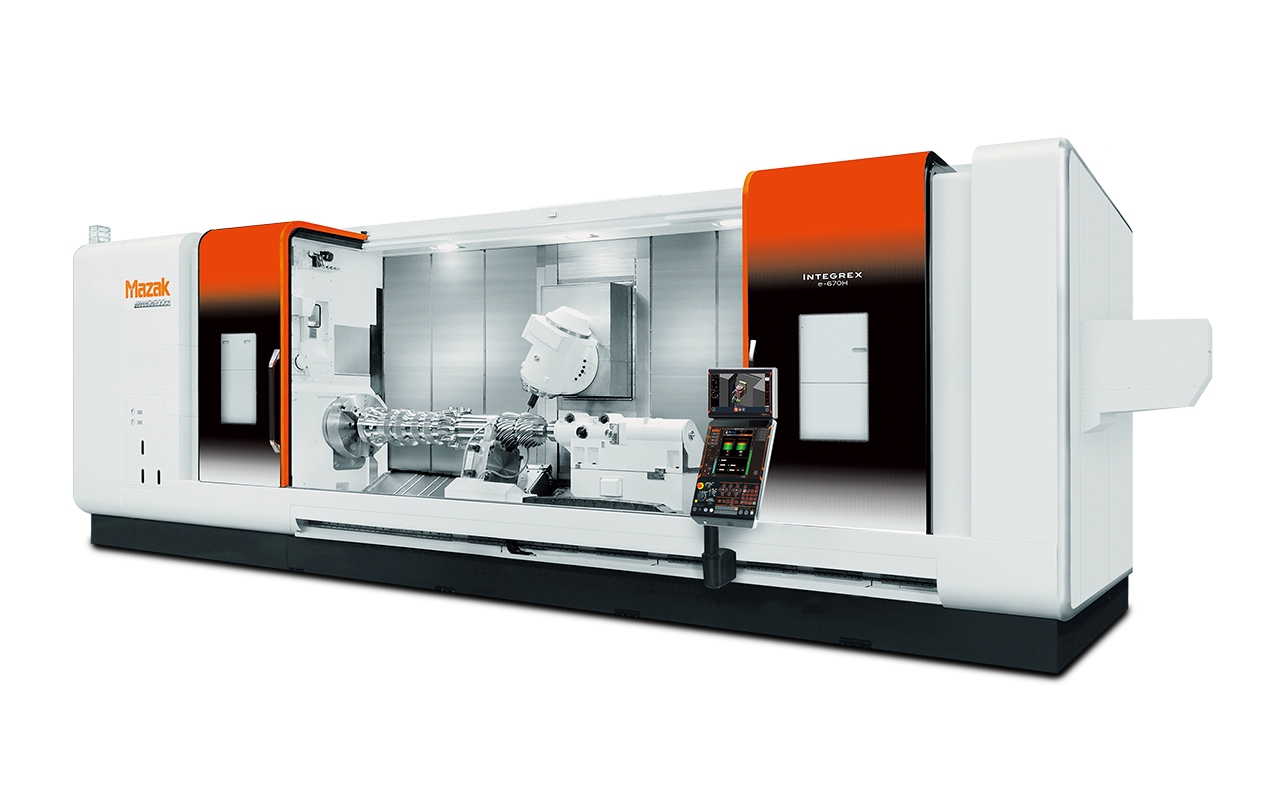

INTEGREX e-H Series

Horizontal multi-tasking machine for long and large diameter workpieces

Machines with a large Y-axis stroke, high output turning spindle, and milling spindle for large-scale machining

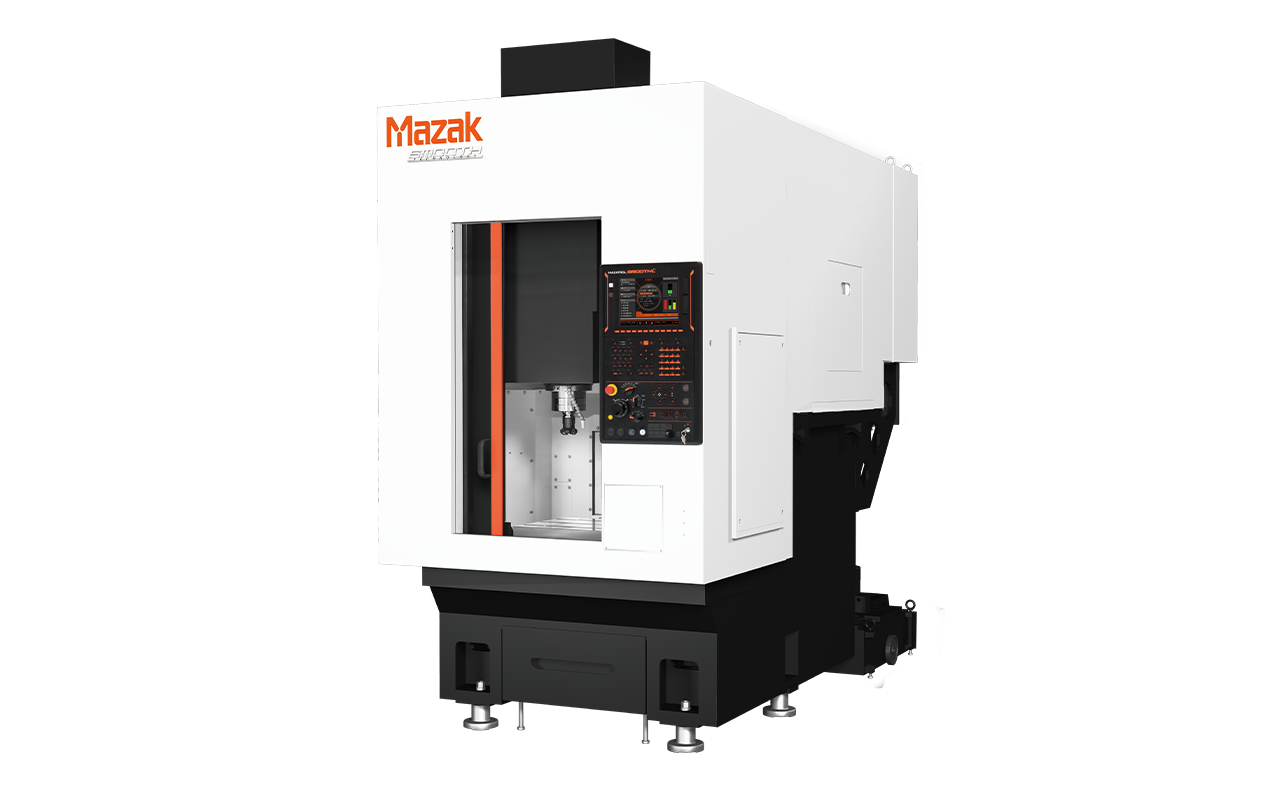

VARIAXIS i NEO Series

Simultaneous 5-axis Vertical Machining Center

The high-performance NEO series with high productivity and low environmental impact technologies

VARIAXIS j Series

High-precision multi-face machining centers

5-axis machining centers with a compact machine design that prioritizes user-friendliness

Global Support

At Mazak, we have established Technology Centers and Technical Centers worldwide to serve as support hubs for customers involved in automotive parts processing. Through our global network, we provide prompt after-sales service to ensure customer satisfaction.