| Tool shank (standard) | BT30 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Table size | 600 mm × 400 mm |

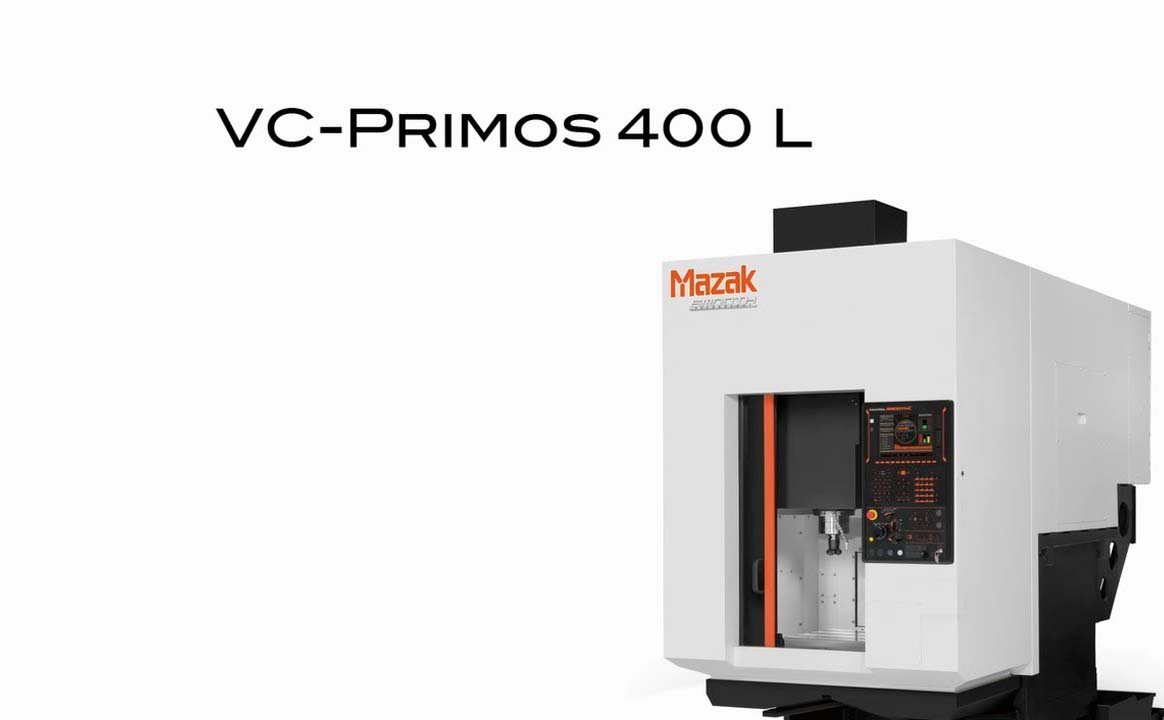

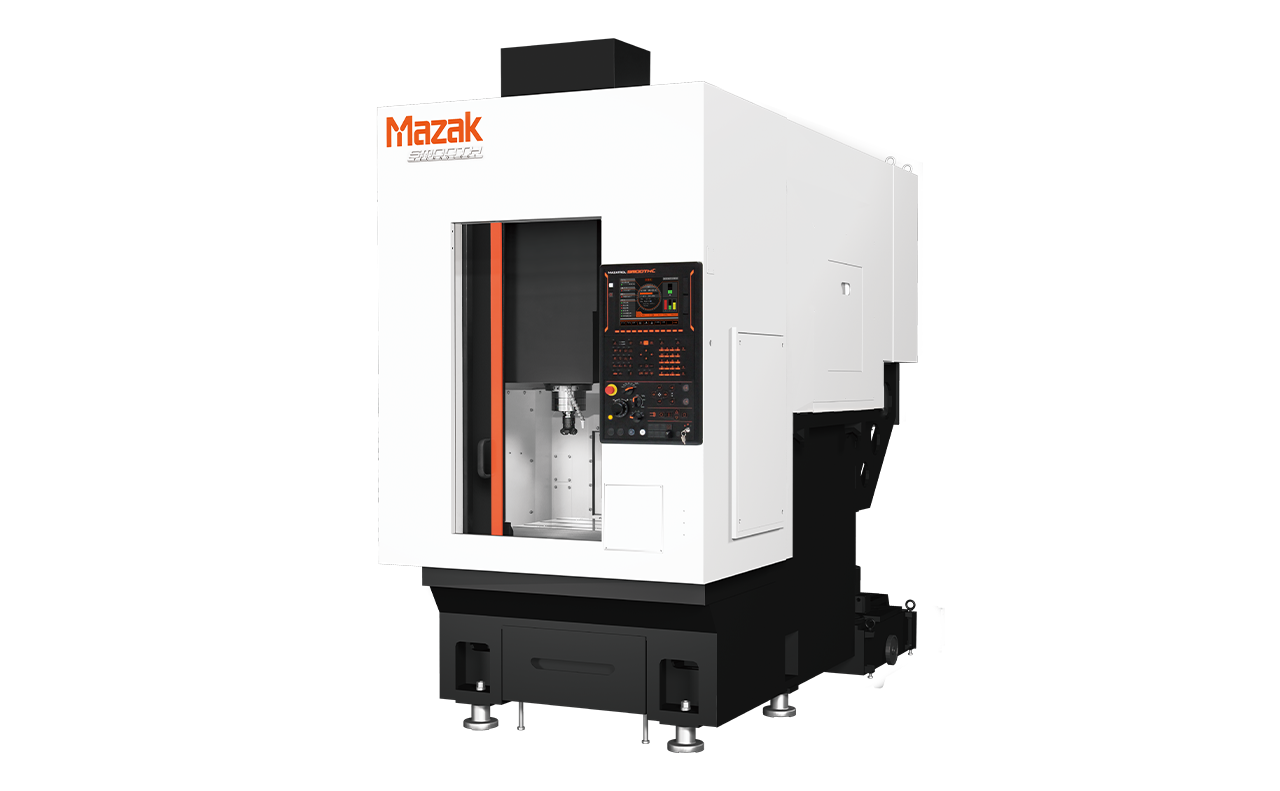

Vertical Machining Centers

VC-PRIMOS

- Equipped with high speed, high accuracy, compact BT-30 spindle for machining small parts

- Machine structure with large table and strokes relative to machine width for improved chips disposal

- Fixed table design for a wide variety of production systems and automation

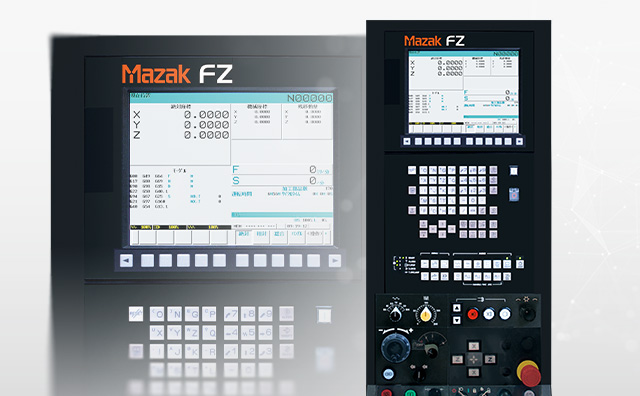

- CNC system can be selected from MAZATROL SmoothC and MAZAK FZ

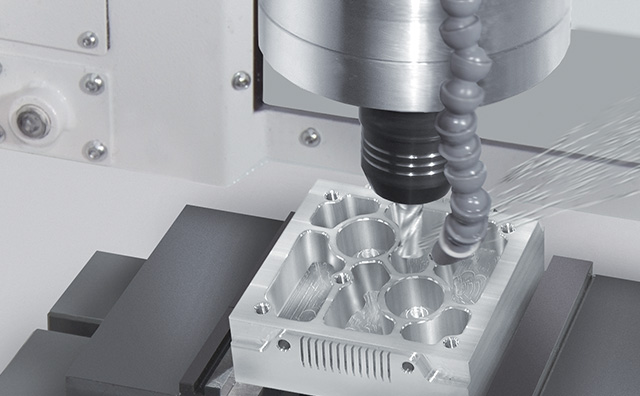

Equipped with high speed, high accuracy, compact BT-30 spindle for small parts machining

Spindle specification for a variety of applications

Equipped with a 12,000 min-1 compact spindle with excellent performance as a standard spindle. Suited for general materials such as iron, cast metal, aluminum, and can operate cutting efficiently.

Standard spindle: 12000 min-1

High speed spindle (option) 20000 min-1

High torque spindle (option) 12000 min-1

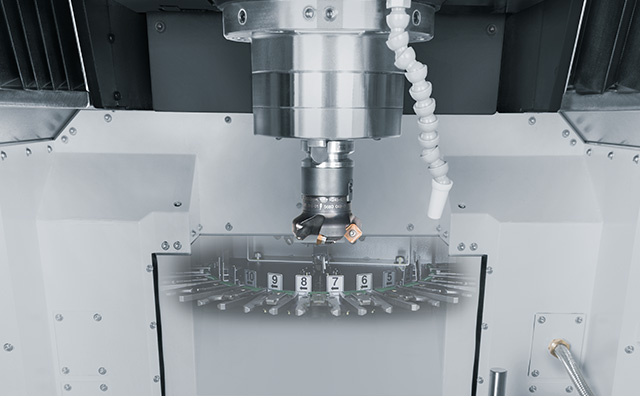

High speed armless tool changer

Tool change time (chip-to-chip): 2.6 sec

The standard tool magazine has a storage capacity of 14 tools. 19 and 21 tool magazines are optionally available.

High speed positioning

Rapid traverse rate (X-, Y-, Z-axis): 60 m/min

Compact, but highly productive

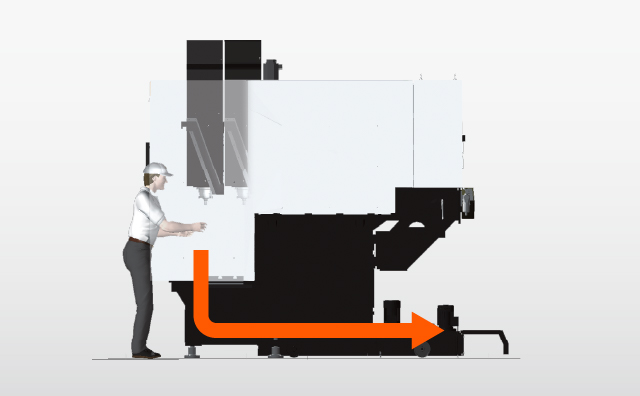

Smallest machine width in its class at 1280 mm

Chips are disposed from the rear side, making daily maintenance space unneeded for the left and right side of the machine. Production line can be organized with minimal space.

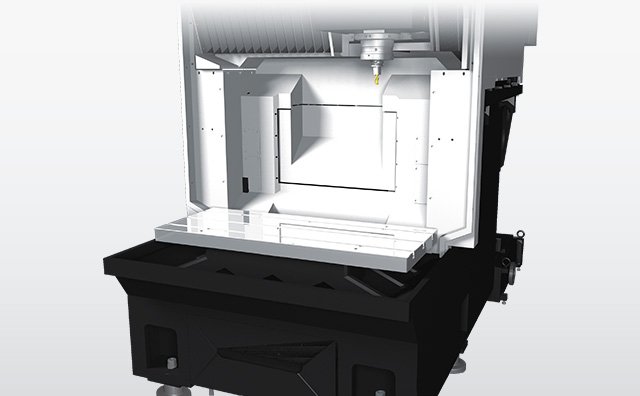

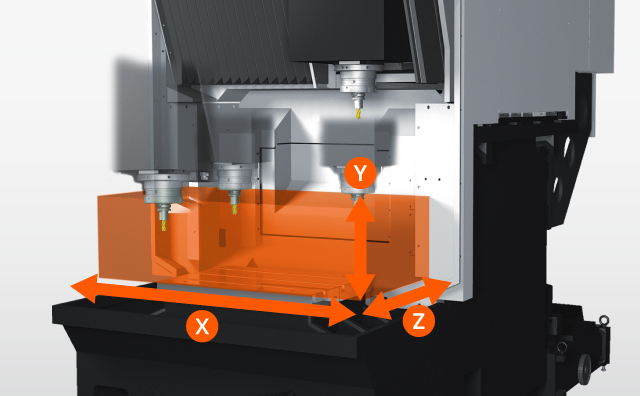

Large machining area

A jig (fixture) can be placed on a 600 mm × 400 mm table within a wide area of 1000 mm × 500 mm.

Stroke

| X-axis (saddle left / right) | 500 mm |

| Y-axis (column front / rear) | 400 mm |

| Z-axis (above / below spindle head) | 350 mm |

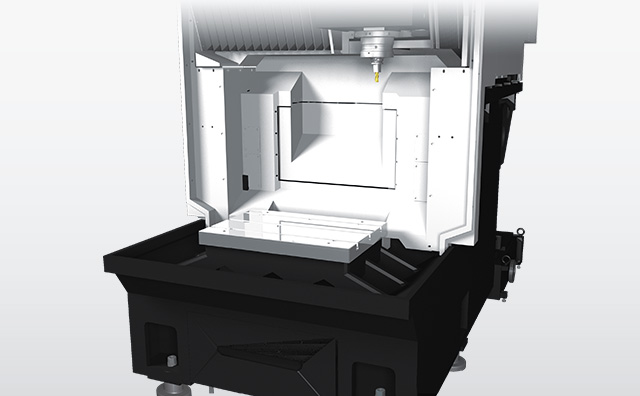

Center trough structure for improved chips disposal

X, Y, Z axes ball screws and servo motors are located on top of machine. Shower coolant is equipped to prevent chips from accumulating as standard, and chips are disposed directly under the table from both the left and right sides. The pull-out chip bucket smoothly collects chips, reducing the operator's workload.

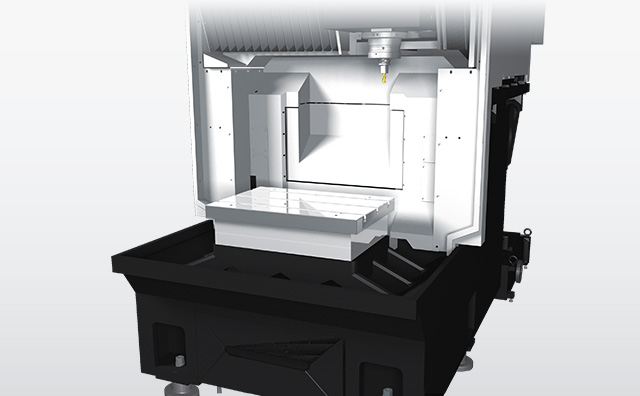

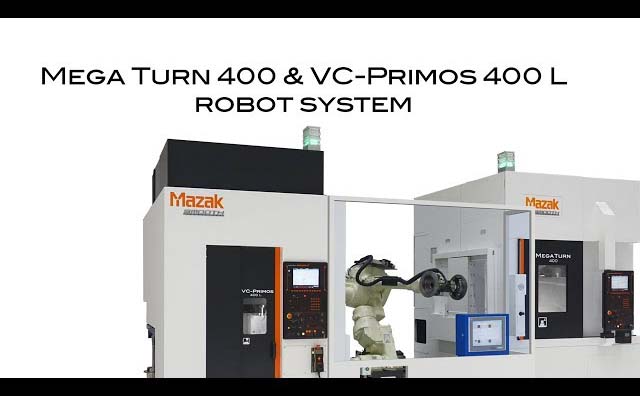

Compatible with various production systems and automation

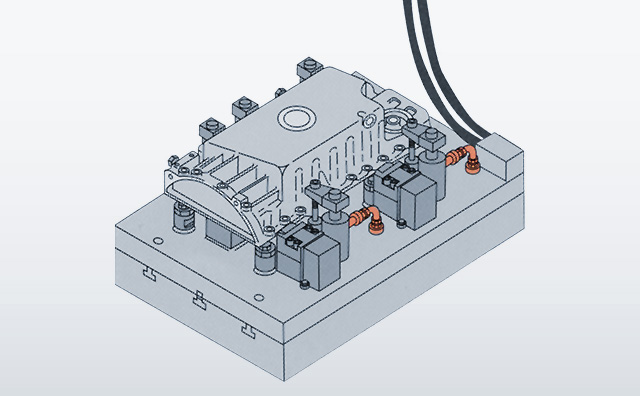

Customizable fixed table design. Easy wiring and piping for NC rotary tables and hydraulic / pneumatic fixtures for a wide variety of production systems and automation

Table Variation

Automation

CNC system can be selected from MAZATROL SmoothC and MAZAK FZ

MAZATROL SmoothC