Machine Tools CNC

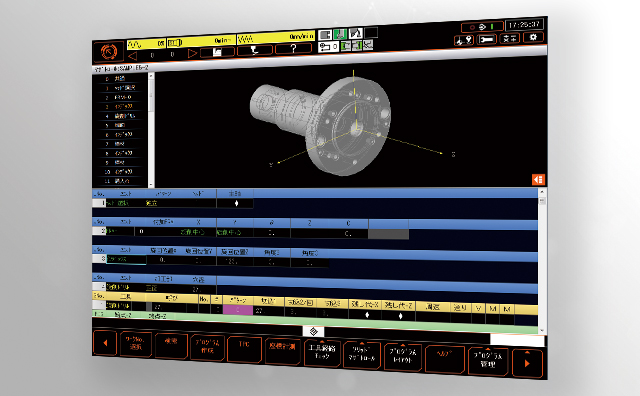

MAZATROL CNC system was introduced in 1981 as the world's first CNC system that enables conversational programming in everyday language. By incorporating features such as 3D model display programming, touch screen interface, and advanced machining cycles, the MAZATROL CNC system continually strives to enhance user-friendliness and efficiency in programming and machining processes. The system continues to evolve by incorporating customer feed back and embracing technological advancements.

Utilizing cutting-edge digital technologies such as AI and digital twins, the system not only enhances operability but also achieves reductions in programming and setup time, shortens cycle time, and stabilizes machining accuracy. Productivity can also be improved by enhancing automation systems. In addition, by linking with digital twin software "MAZATROL DX", it becomes possible to perform digital setup in the office, which greatly improves the machine utilization rate.

SOLID MAZATROL

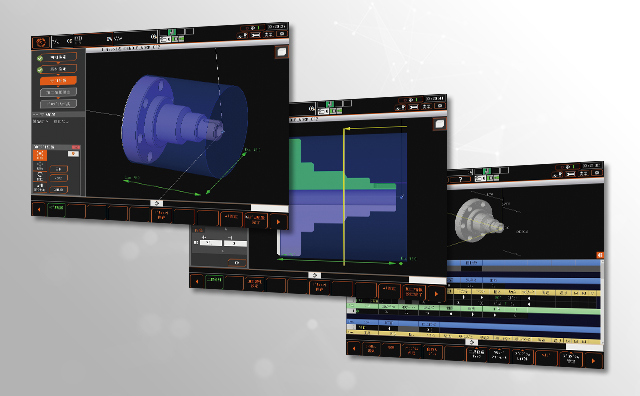

MAZATROL programs can be automatically generated from 3D models created with commercially available CAD software, greatly reducing program man-hours. By learning machining know-how from programs created in the past, AI can generate optimal machining programs.

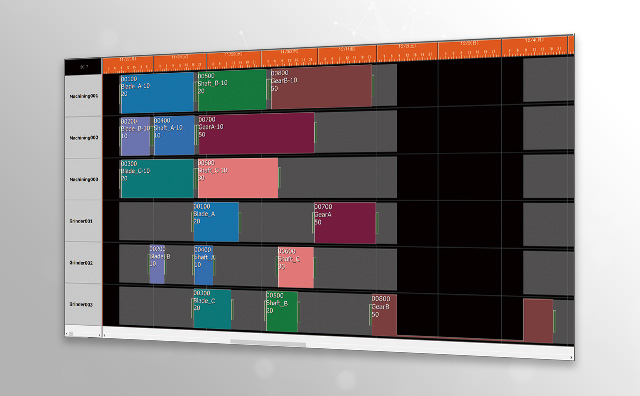

Optimum machining process thanks to AI learning

AI utilizes machining expertise from accumulated programming experience. Based on the know-how, the machining process and processing conditions are automatically estimated and output as an optimal program.

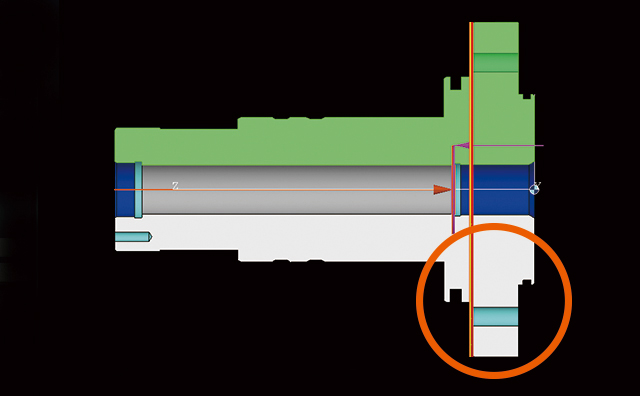

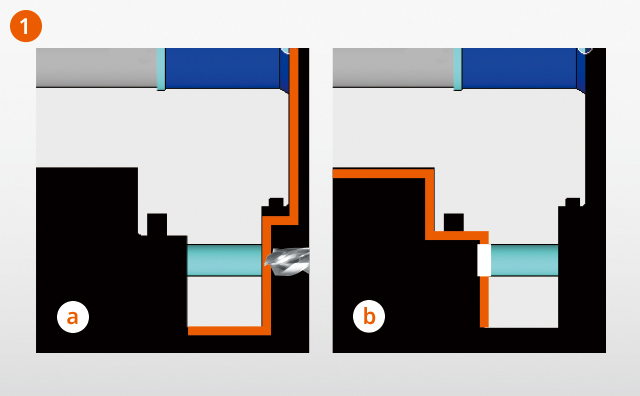

- 1: |[Without AI training]

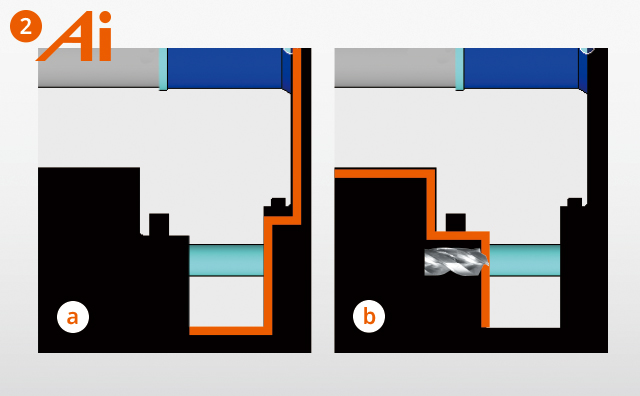

Interrupted cutting will be required in second process which will affect finished surface. - 2: |[With AI training]

Drilling is performed in the second process for high accuracy finished surface.

Examples of inferences (process division of machining)

Drilling/Turning

b: Second process

Turning

Turning

b: Second process

Drilling/Turning

- Example 01

- Example 02

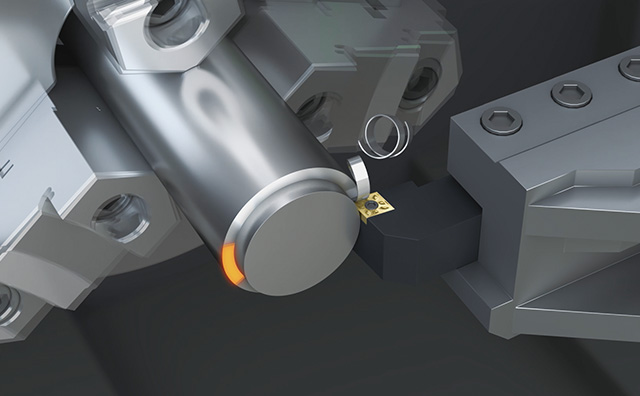

Overwhelmingly high-speed and high-accuracy CNC

Latest hardware and software for unprecedented speed and precision

Smooth graphical user interface

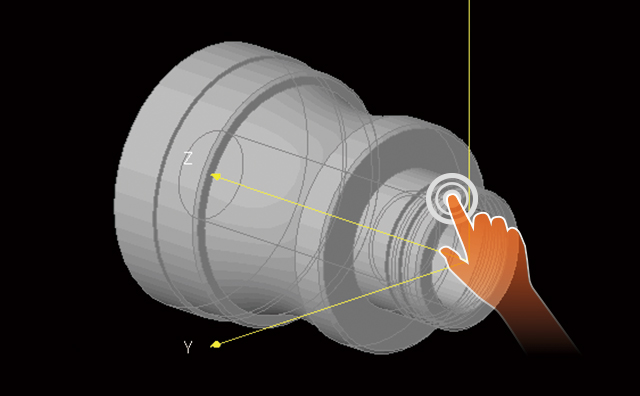

19-inch touch screen and 3D model-based graphical user interface for intuitive operation similar to that of smartphones and tablets

Designed for unsurpassed ease of operation

Smooth process management and advanced programmability

By linking with the optional MAZATROL DX, virtual machines accurately duplicate the operation of machines on your factory floor. Work efficiency is improved by digital setup.

Standard model CNC system for ease of operation

Ez Operation

Enhanced MAZATROL programming "QUICK MAZATROL"

15-inch touch screen for intuitive operation

Screen is designed for ease of use and display can be customized.

Ez Machining

Equipped with heat displacement compensation system "Thermal Shield"

SMC (SMOOTH MACHINING CONFIGURATION) can adjust machining features according to the processing shape and method.

Ez Setup

By linking with the optional MAZATROL DX, virtual machines accurately duplicate the operation of machines on your factory floor. Work efficiency is improved by digital setup.

Flexible layout

You can customize the layout of the CNC screen, including the displayed data, menus, and on-screen keyboard.

Moving the keyboard to a position that suits the height reduces the load on the operator.

Customizable display

You can display any combination of information. By customizing the combination according to the work process, you can check the data and work with a minimum of screen transitions.

QUICK MAZATROL

QUICK MAZATROL prevents programming errors and shortens the time required for programming. The use of a touch panel and 3D product models make it easy to create and check programs.