| Spindle bore | Φ61 mm |

| Chuck size | 6″ |

| Max. machining diameter | Φ300 mm |

| Max. machining length | 620 mm |

CNC Turning Center

HQR

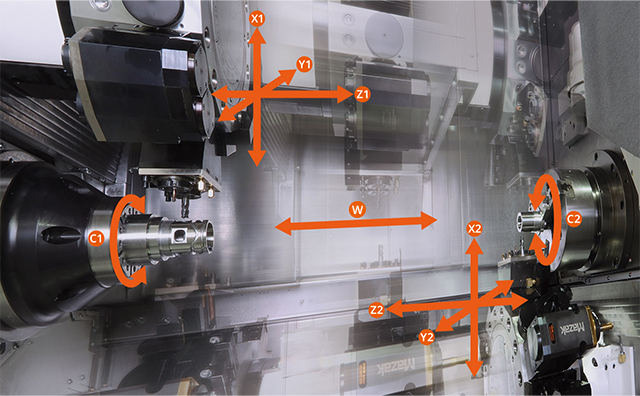

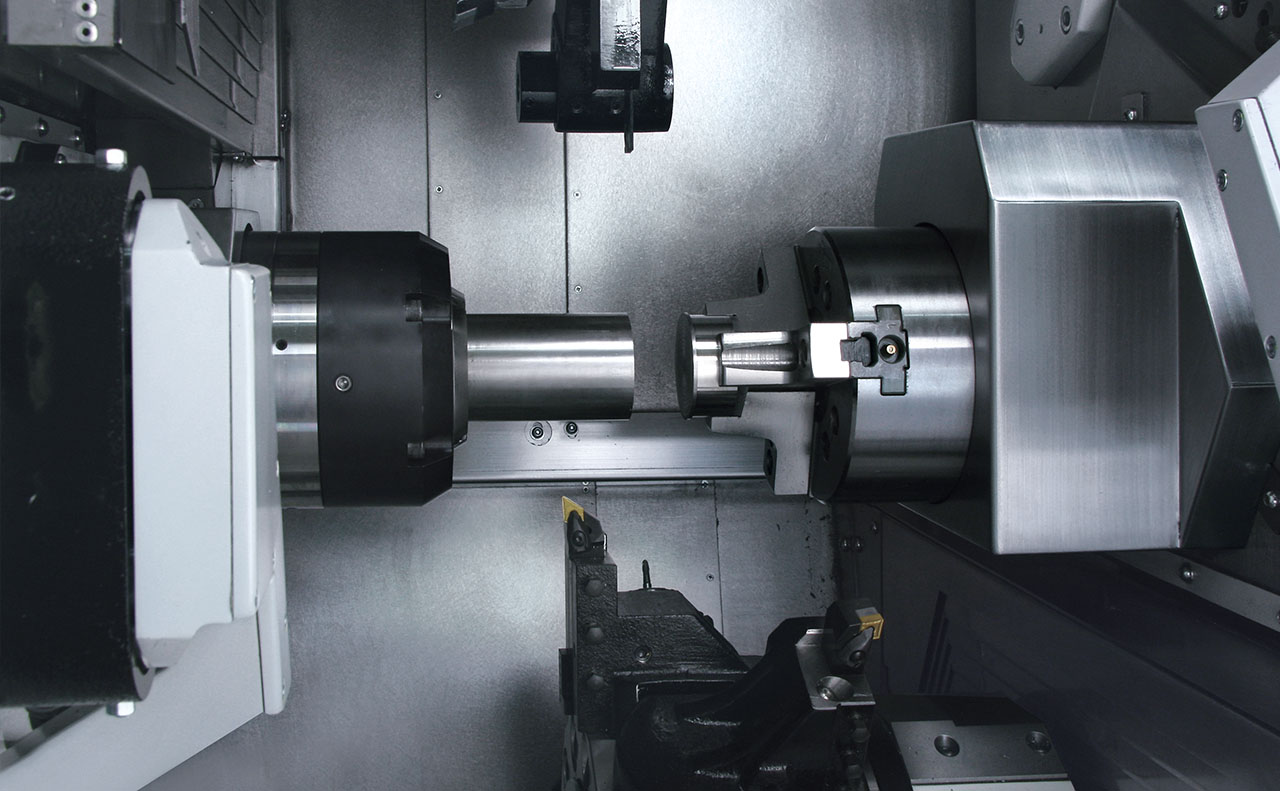

- 2 turret / 2 spindle configuration for significantly reduced cycle time

- Easy programing of balance cutting and simultaneous left and right machining with the conversational MAZATROL program

- Long-term automatic operation enabled by optional bar feeders, work loaders, and other automation options

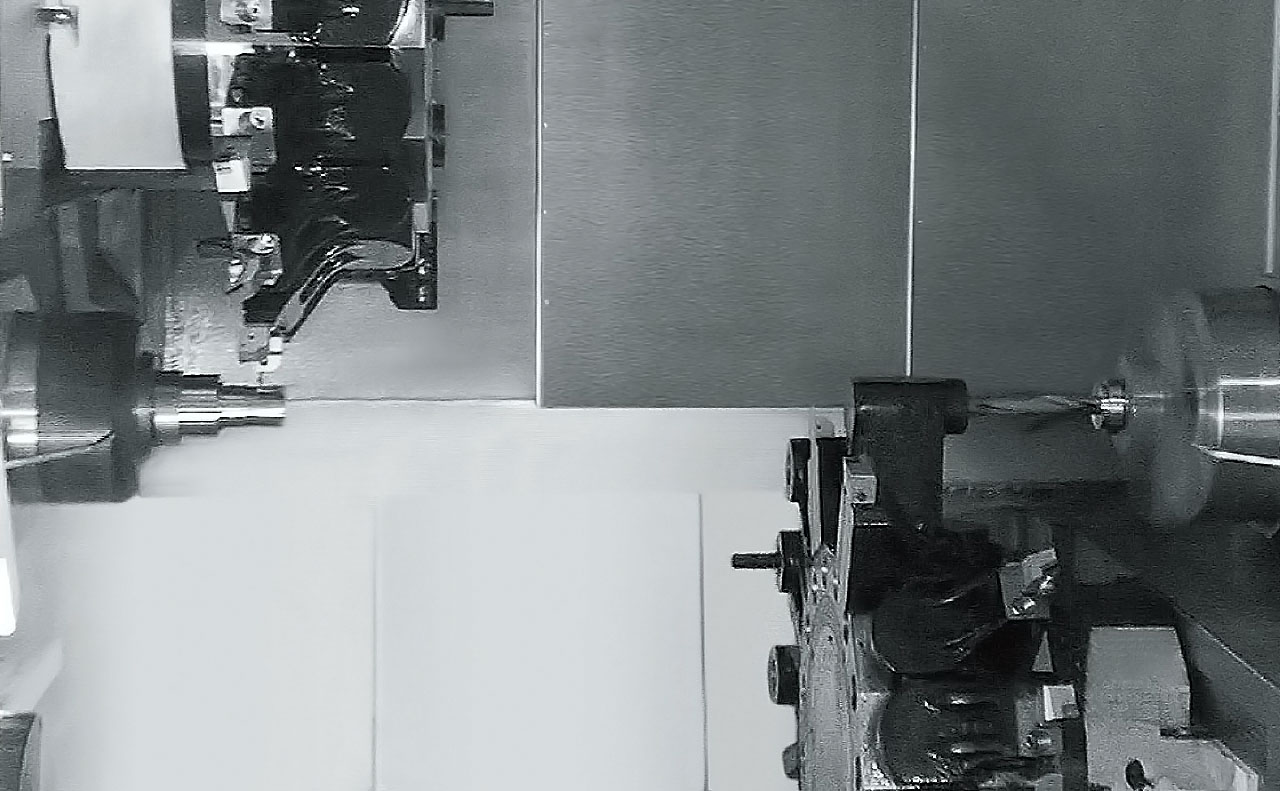

Machine construction for significantly reduced cycle time

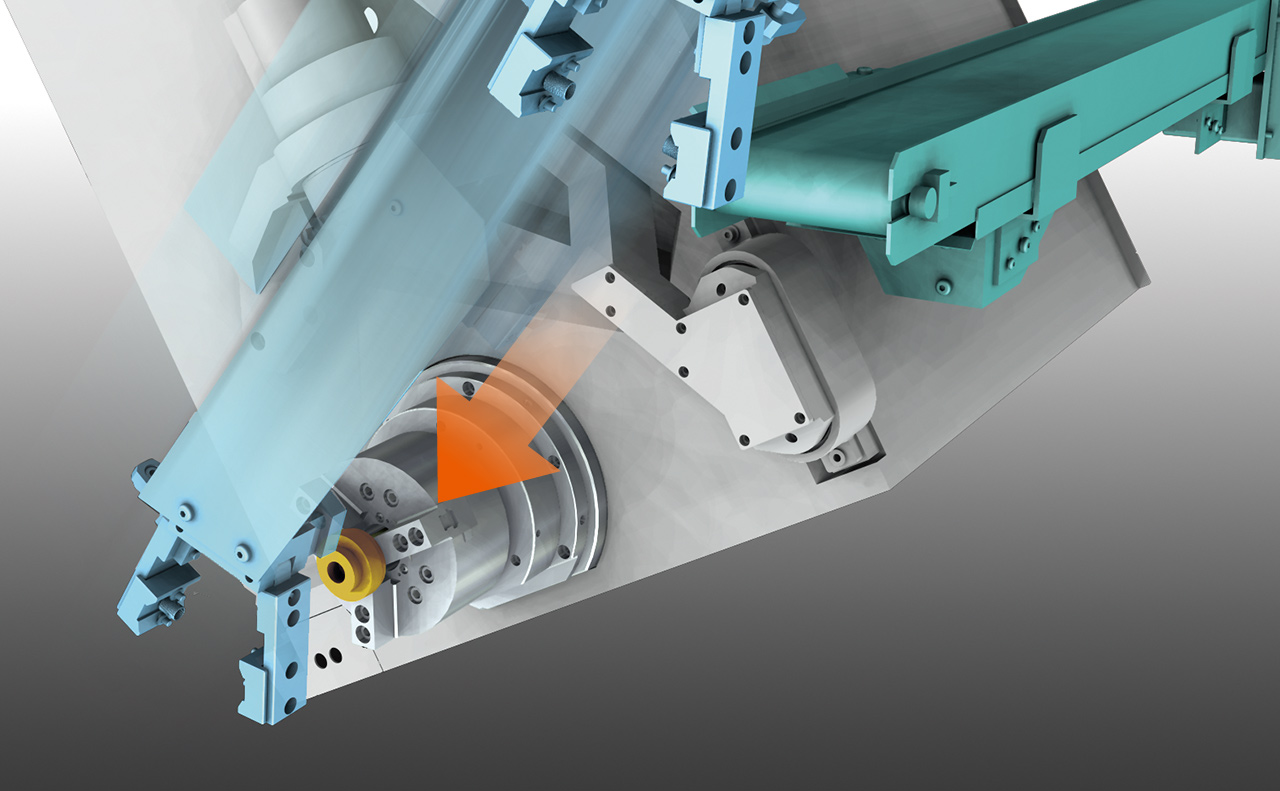

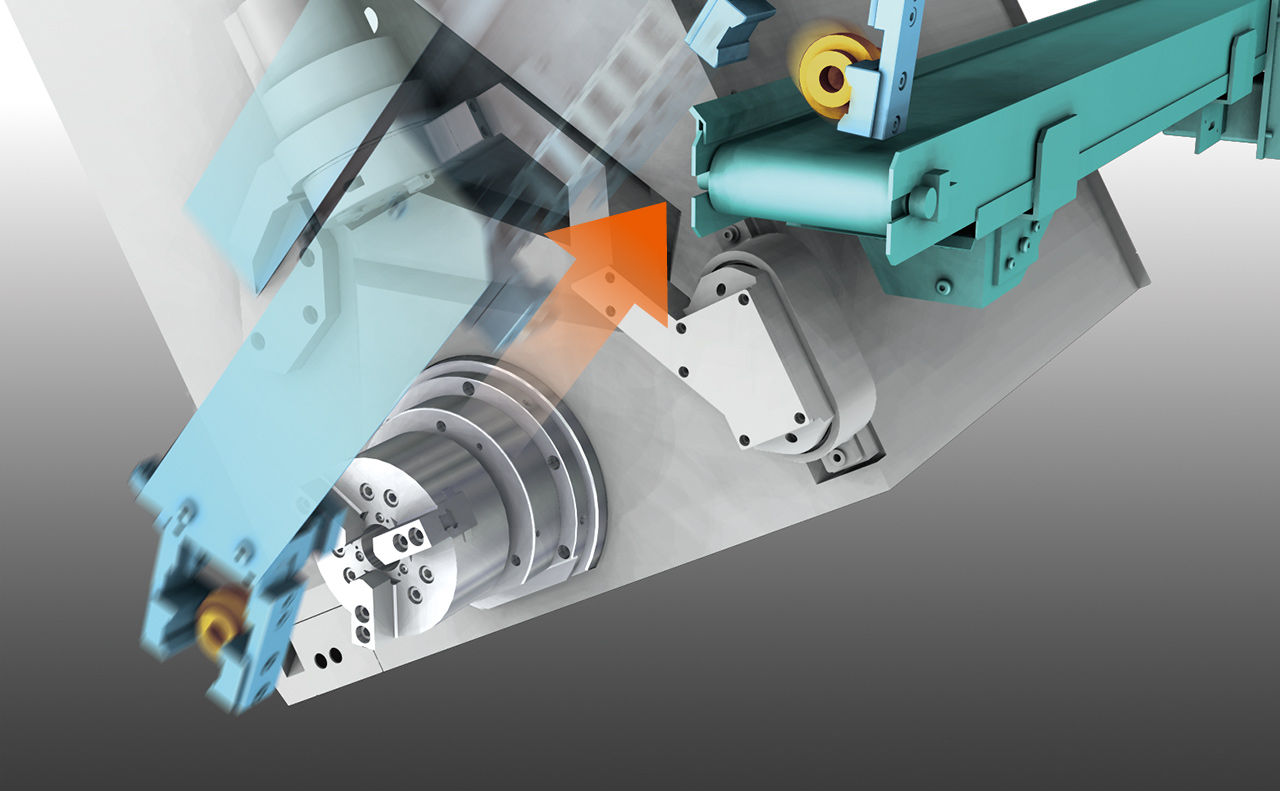

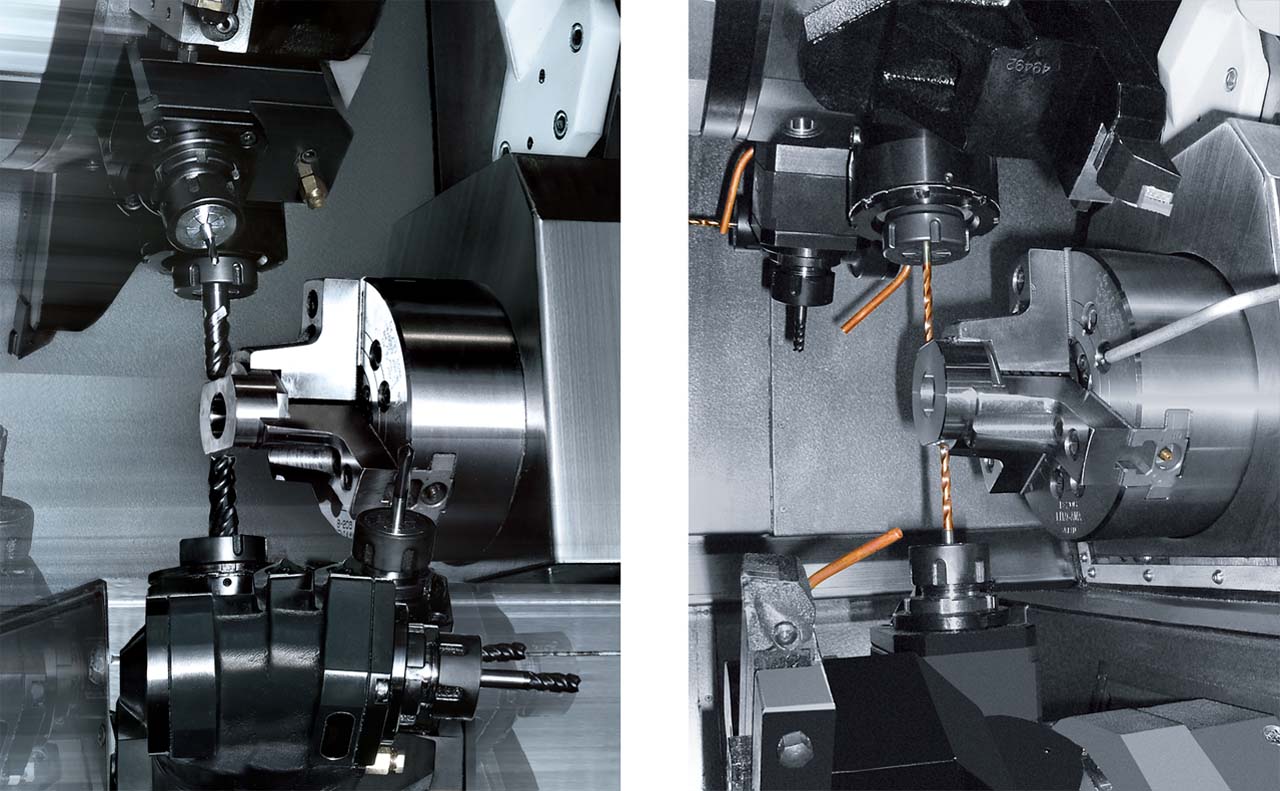

Simultaneous machining with upper and lower turret to significantly reduce cycle time

The upper and lower turrets are arranged in a straight line in the X-axis direction. By synchronized machining of both turrets, balance cutting that minimizes workpiece displacement can be performed. Additionally, simultaneous turning of the left / right workpieces reduces cycle time.

W: 2nd spindle (W-axis)

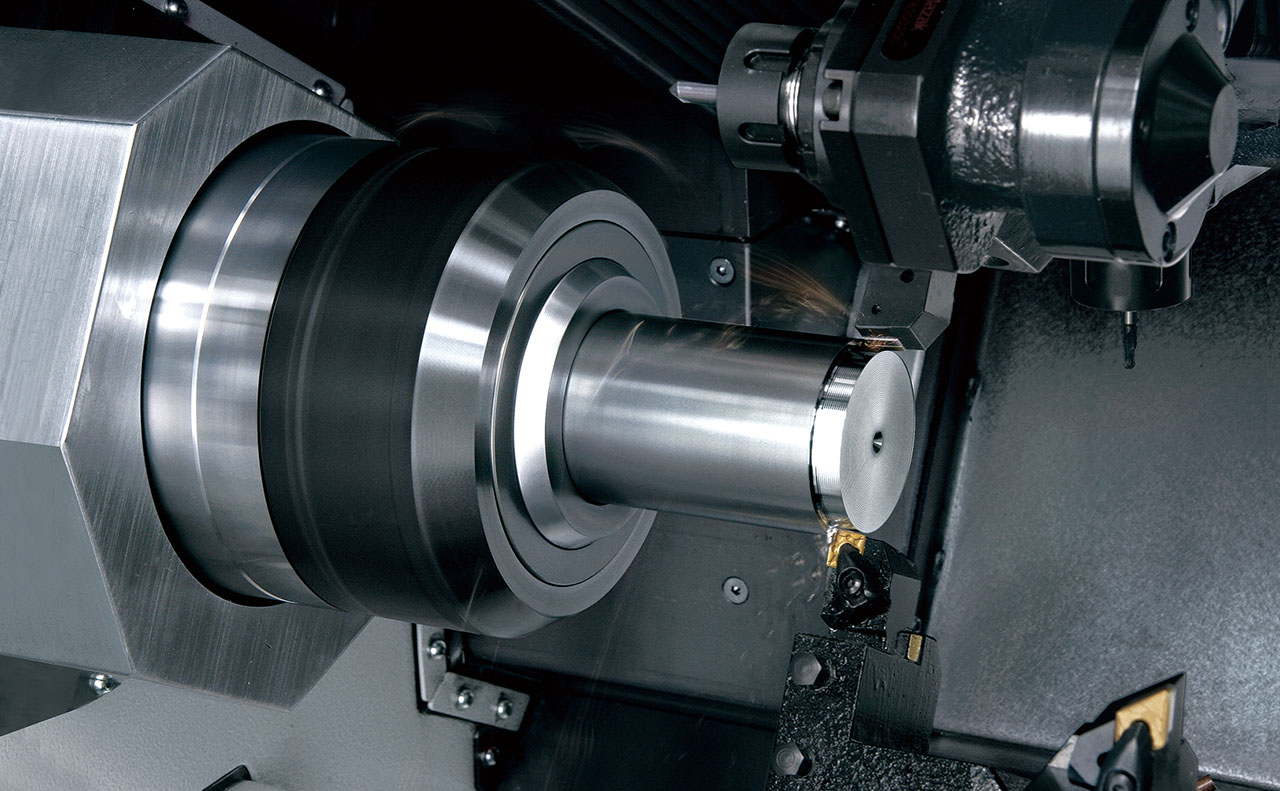

Balanced turning on main spindle

Simultaneous machining of two workpieces

Balanced milling on second spindle

Cut-off

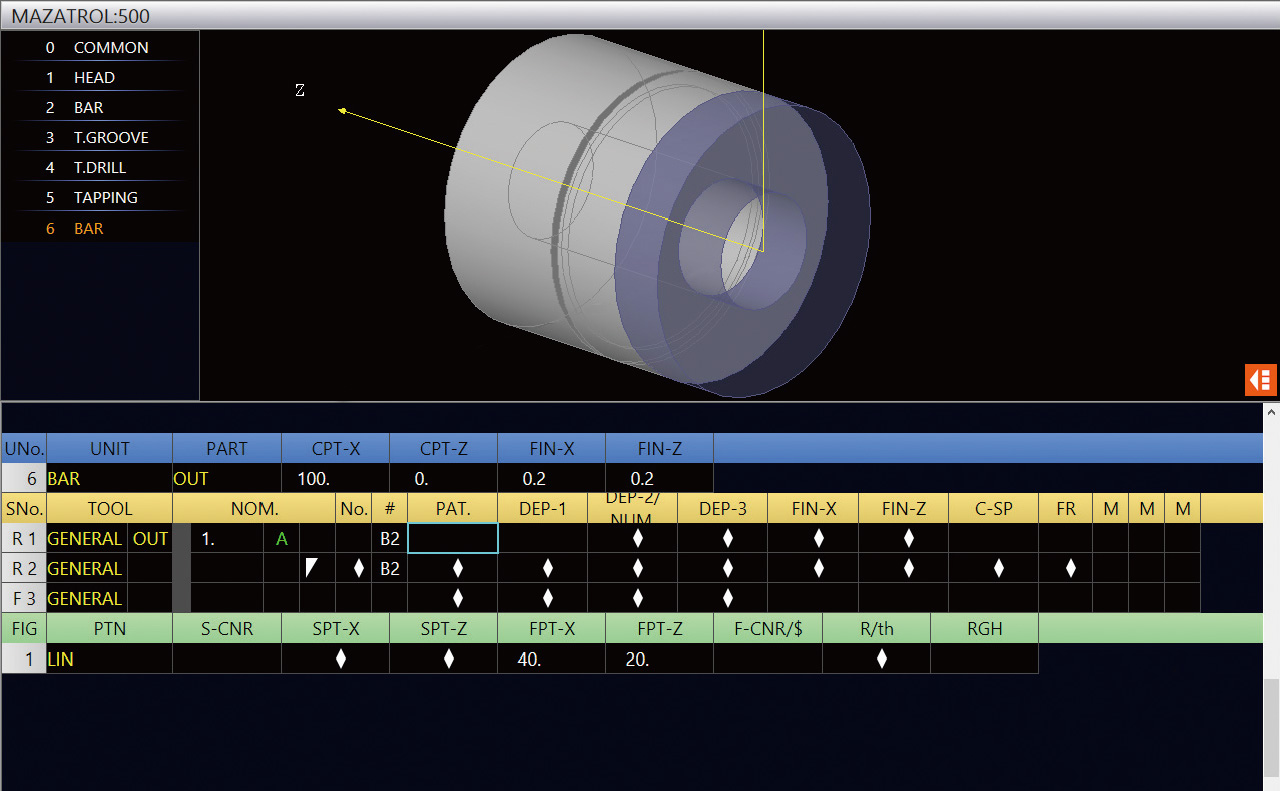

Simplified programming

The conversational MAZATROL program can simplify programming for various machining operations. High-efficiency machining programs that utilize the upper and lower turrets and the main and second spindles can also be easily created. It is also possible to create programs in EIA/ISO programs.

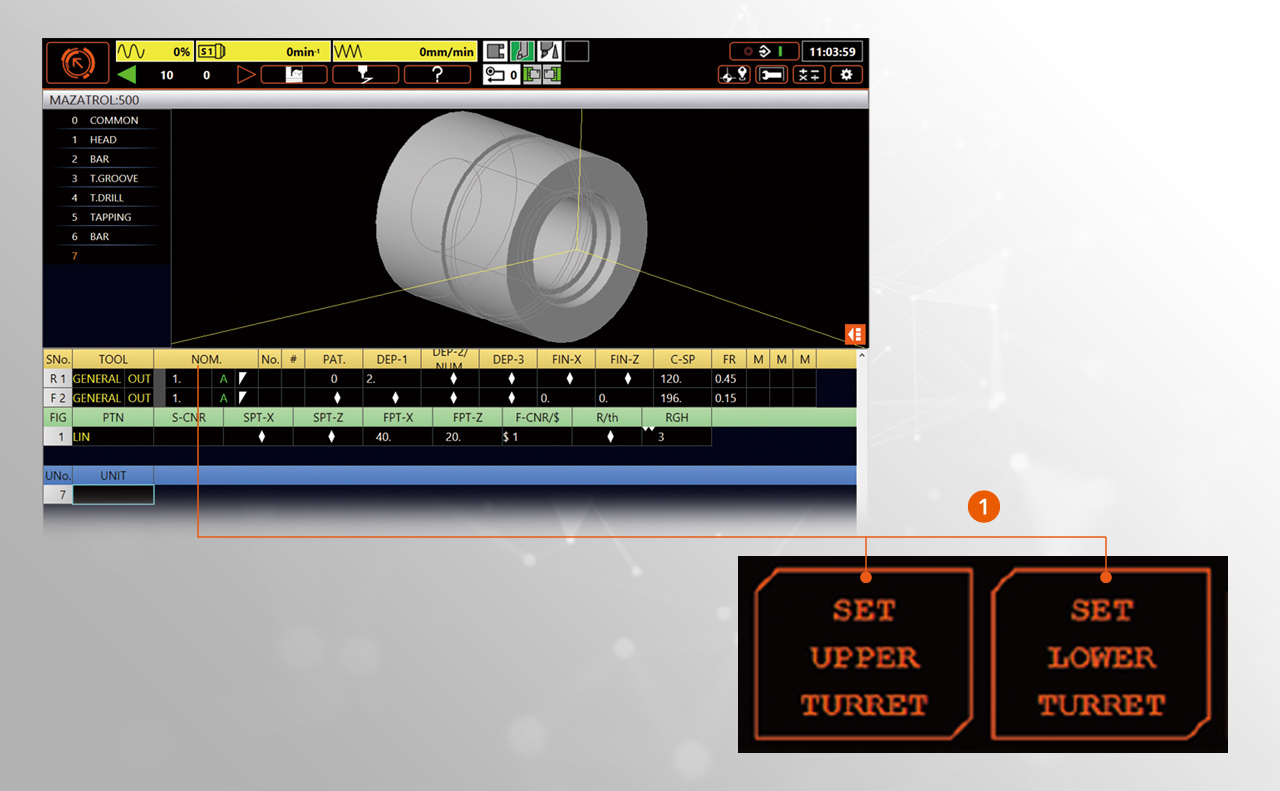

Easy programming of upper and lower turrets

By simply selecting requirements for machining - such as workpiece material and surface finish - from the conversational menu and inputting data, cutting conditions and the tool path are automatically made. Different from standard EIA / ISO programs, the feedrate for each axis movement does not have to be determined and input.

To use the lower turret, all that is required is to input the "lower turret mark” to the respective tool. Single, simultaneous, and balanced cuts with upper and lower turrets can also be easily created with the conversational program.

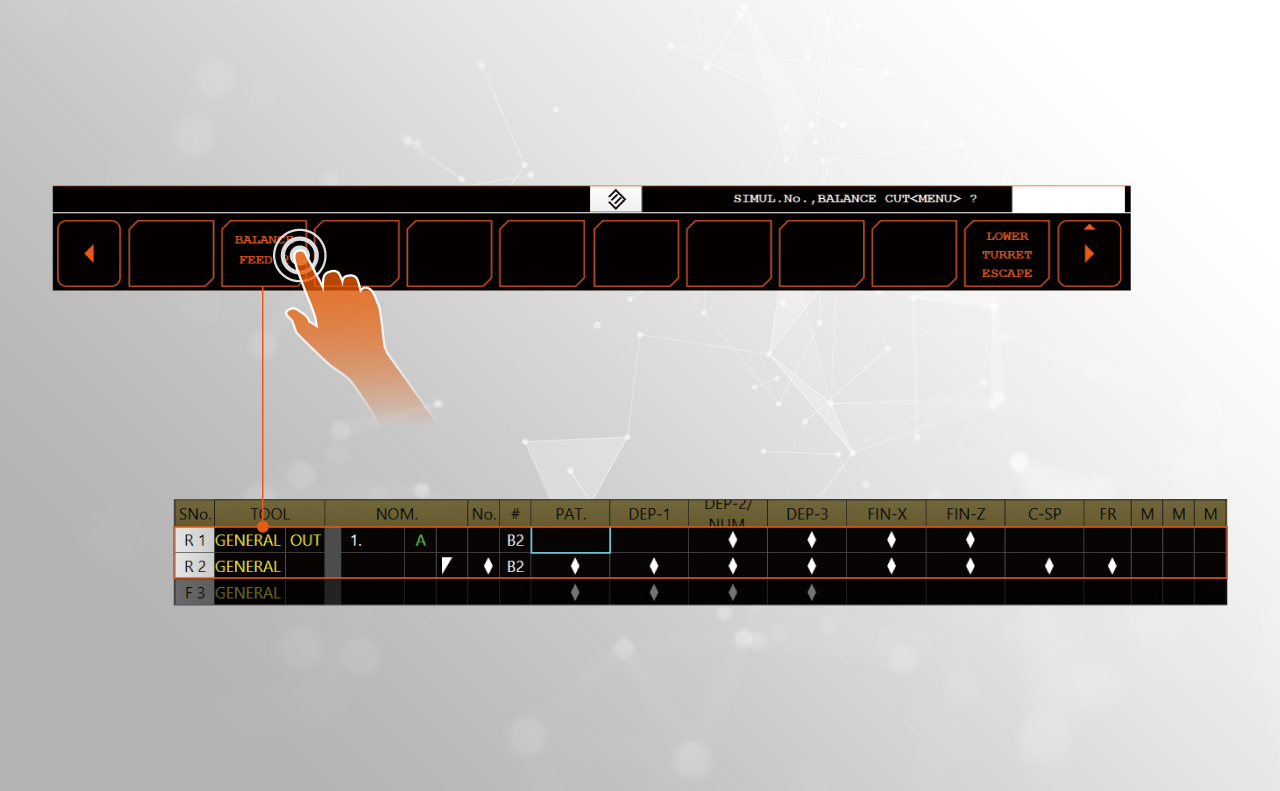

Simple programming for balance cutting

The balance cut program can be conveniently made by just selecting balance cut on the turning program unit.

Pursue even higher productivity through automation

A variety of automation equipment such as bar feeders, workpiece unloaders and robots are optionally available support long-term automatic operation.

Bar feeder and workpiece unloader

Effective operation from bar material to finished workpiece. By using a workpiece unloader instead of the auto parts catcher, the workpiece is removed from the machine without damaging the high-quality finished surface.

- Step 1

- Step 2

Reference Video

HQR-100MSY

HQR-150MSY

| Spindle bore | Φ76 mm |

| Chuck size | 6″ |

| Max. machining diameter | Φ300 mm |

| Max. machining length | 620 mm |

HQR-200MSY

| Spindle bore | Φ76 mm |

| Chuck size | 8″ |

| Max. machining diameter | Φ344 mm |

| Max. machining length | 860 mm / 1325 mm |

HQR-250MSY

| Spindle bore | Φ91 mm |

| Chuck size | 10″ |

| Max. machining diameter | Φ344 mm |

| Max. machining length | 860 mm / 1325 mm |