| Chuck size | 8″ |

| Max. machining diameter | Φ500 mm |

| Max. machining length | 500 mm / 1016 mm |

Multi-Tasking Machines

INTEGREX j

- Exceptional milling versatility makes up the weak points of turret lathe

- DONE IN ONE machine for all processes

- CNC system designed for ease of use

Make up for weak points of turret lathe

Weak points of turret lathe

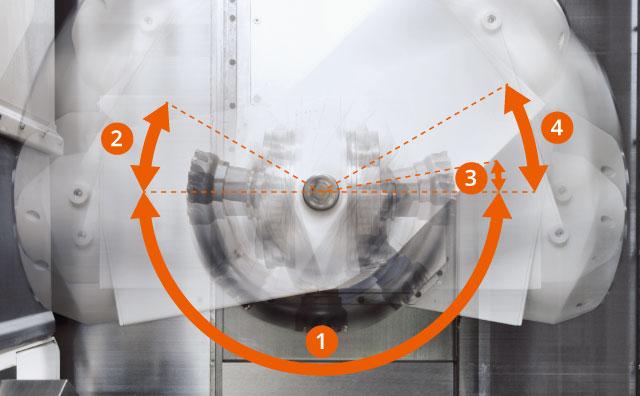

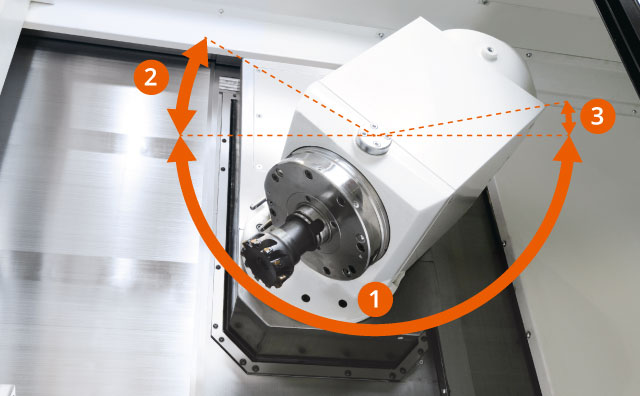

Exceptional milling versatility for multi-face machining

The milling spindle unit can be indexed in 5 degree increments from -30° to 190°, enabling outer diameter machining, end facing, and diagonal machining to be performed with a single tool. As a result, machining cycle times can be reduced without changing tool. 1 degree indexing specifications are also available as an option.

- 1: |180°

- 2: |30°

- 3: |10°

- 4: |30° *30° indexing only for INTEGREX j-200S

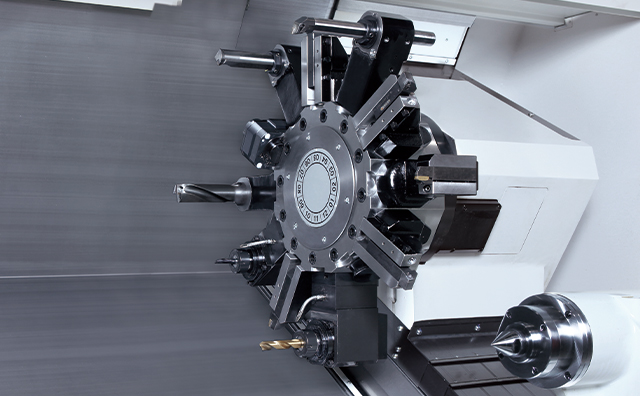

High-performance milling spindle

The milling spindle has a substantial cutting capacity equivalent to that of small machining centers and achieves high productivity.

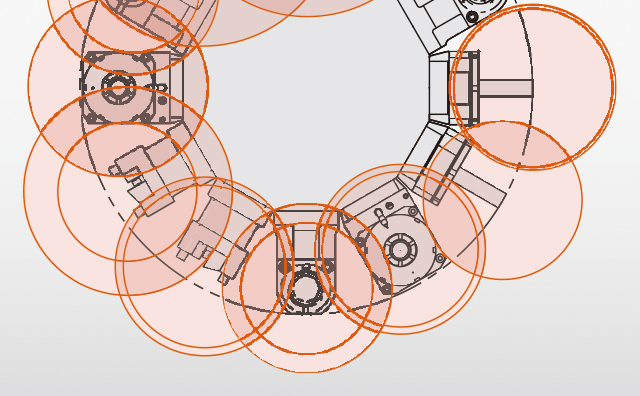

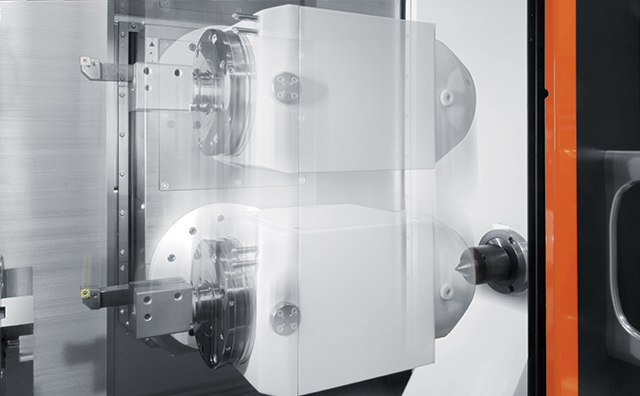

Machine design considering interference

The tailstock has sufficient stroke so that it does not interfere with the milling spindle. The same is true for the second spindle. The setup can be performed without any interference, resulting in improved work efficiency.

Increased efficiency of setup

Front-positioned tool magazine

The tool magazine (20 tools as standard and 36 or 72 tools as option) is conveniently located at the front of the machine for easy tool setups.

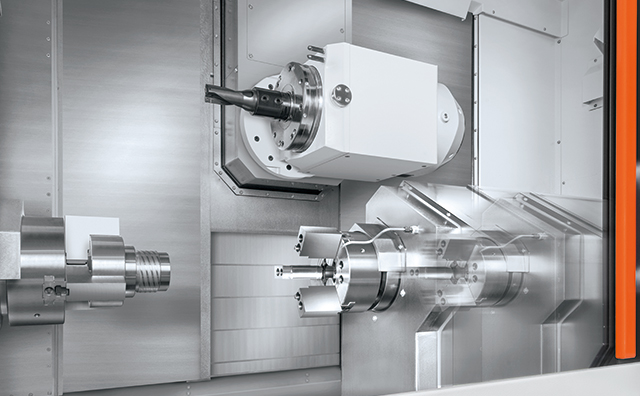

Second spindle performs continuous machining (INTEGREX j-200S)

The second spindle is a built-in motor spindle equivalent to that of the main spindle.

This is effective in reducing setup time for workpieces that require phase alignment.

High productivity and high-accuracy machining without C-axis indexing

The machining area is large and has a long stroke. The X-axis and Y-axis have large traveling travel, allowing machining without C-axis indexing, such as milling the edge of a workpiece, for high productivity and accuracy. Since the tools not in use are outside the machine, machining can be done without worrying about interference more than with a turret lathe.

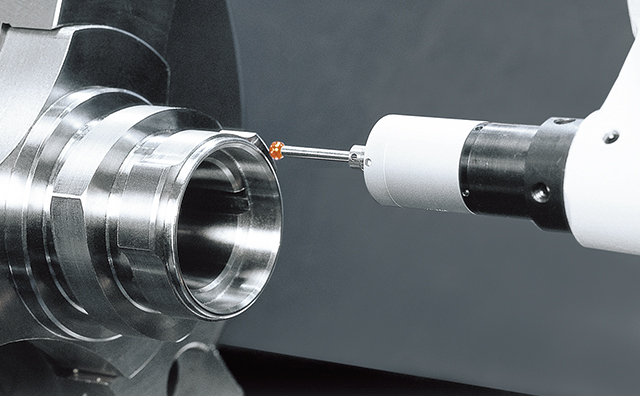

Stable, high positioning accuracy and high-accuracy machining

High accuracy coupling realizes high machining accuracy

The milling spindle turret (B-axis) is clamped by a high-precision index coupling to achieve the same high indexing accuracy as a turning center with drum turret.

- 1: |180°

- 2: |30°

- 3: |10°

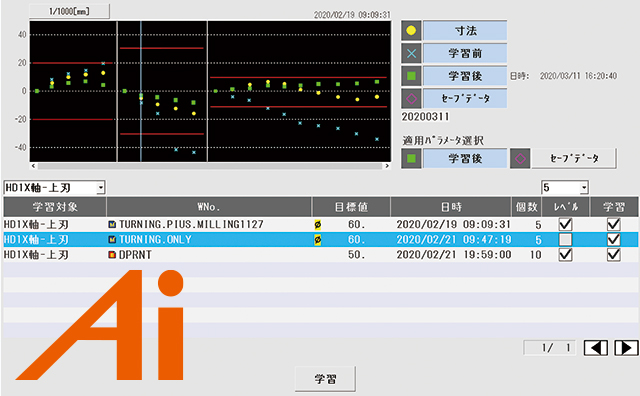

Ai Thermal Shield

Based on spindle speed and temperature of the machine, Ai Thermal Shield suppresses changes in the cutting edge position. It stabilizes continuous machining accuracy through meticulous machine control that takes into account temperature changes, machine position, coolant ON/OFF, and other factors. New algorithms have improved the accuracy of compensation. Furthermore, by accumulating and learning data from subsequent measurements, thermal displacement compensation can be optimized for each machining environment to stabilize machining accuracy.

- Machining

- Workpiece inspection

- Simulation

Reference Video

INTEGREX j-200

INTEGREX j-200S

| Chuck size | 8″ |

| Max. machining diameter | Φ500 mm |

| Max. machining length | 910 mm |

INTEGREX j-300

| Chuck size | 10″ |

| Max. machining diameter | Φ500 mm |

| Max. machining length | 629 mm / 1165 mm |

INTEGREX j-400

| Chuck size | 12" |

| Max. machining diameter | Φ500 mm |

| Max. machining length | 629 mm / 1165 mm |