| Distance between columns | 2650 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 4000 mm × 2000 mm |

Vertical Machining Centers

FJW

- A 5-surface machining center with capacity for powerful cutting of large workpieces and process integration

- Angle head attachment comes as standard equipment

- Equipped with a BT50 high torque spindle, effective in rough machining of steel and cast iron.

- Column height of 1650 mm achieved by utilizing W-axis controlled cross rail

- Machine design to simplify the machining of large workpieces

- Equipped with touch screen CNC system MAZATROL SmoothG

Powerful cutting of large workpieces and process integration

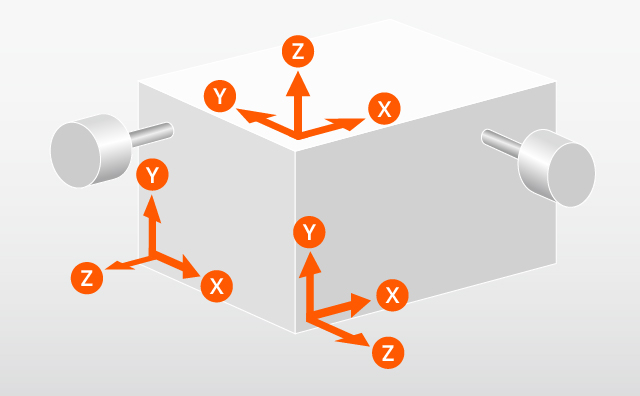

Process integration by 5 face machining / Large workpiece capacity / High-power machining

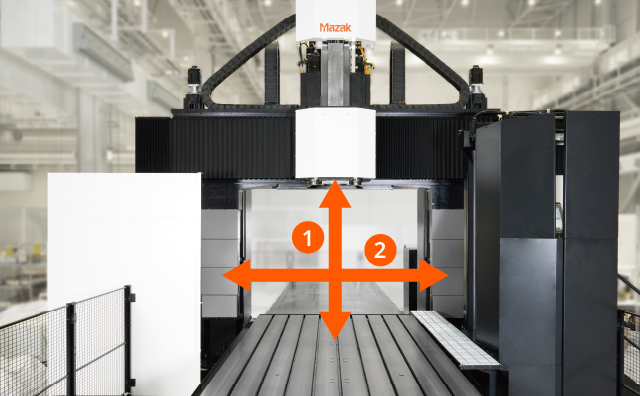

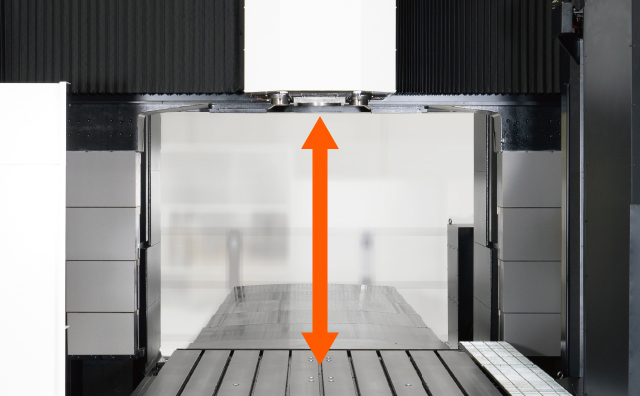

- 1: | Column height: 1.65 m

- 2: | Distance between columns: 2.65 m

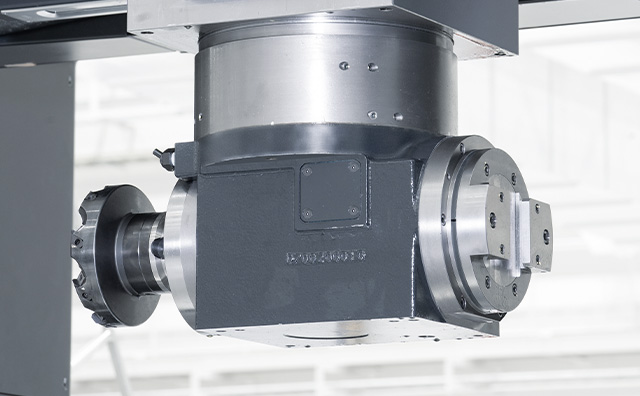

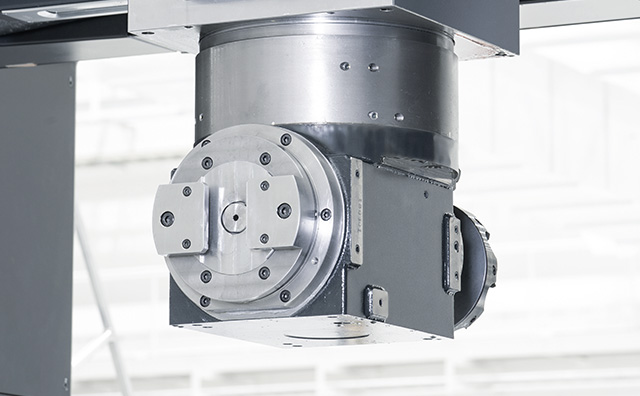

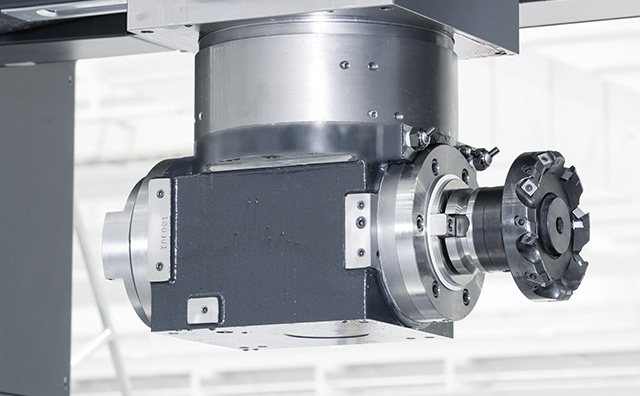

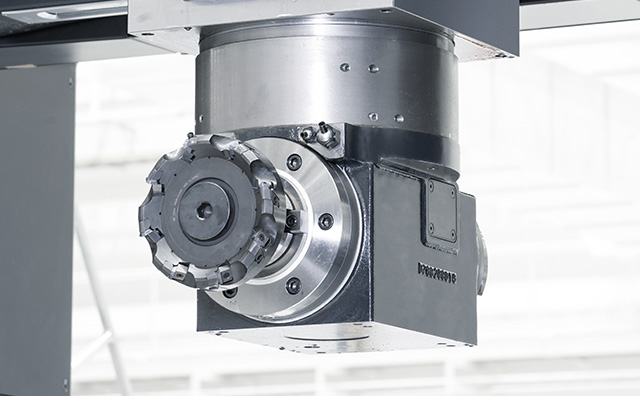

Comes standard with a compact angle head attachment

The angle head attachment can be automatically attached to and detached from the spindle. It can also automatically change the tools.

It can be indexed to 72 positions every 5°, allowing continuous machining of the top and side surface .

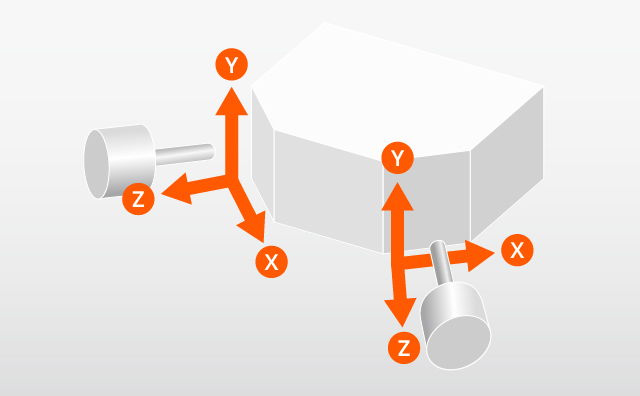

Program functions for 5 face machining and 5° index machining

Convenient programming for 5 surface machining with MAZATROL conversational program

Programs for 5 face machining can be made by G code (EIA/ISO) programs and machining by angle head attachment every 5° indexing can be performed.

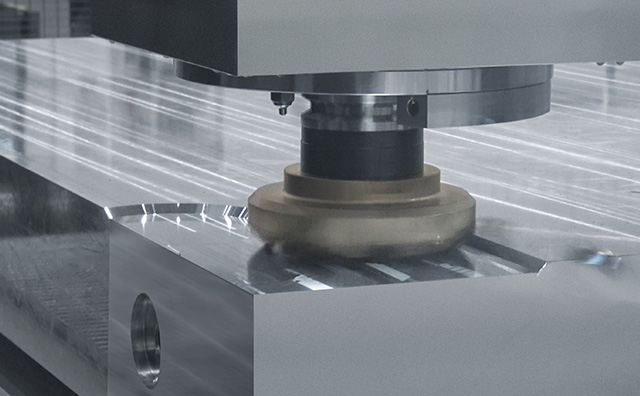

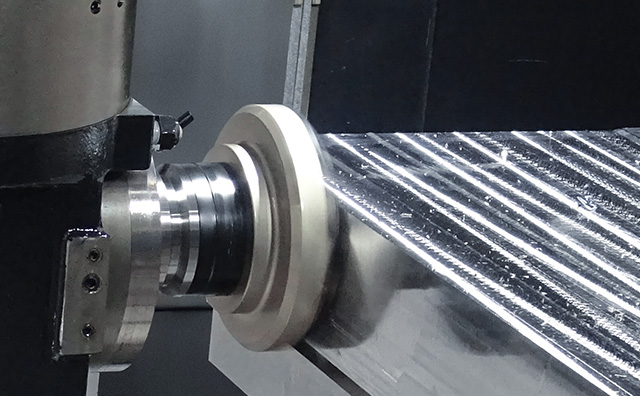

Equipped with BT50 high torque spindle for powerful cutting

High torque spindle with a maximum torque of 828 N・m

Equipped with a high torque spindle with a maximum speed of 6000 min -1 and a maximum torque of 828 N・m [40% ED]. It is effective for rough machining of materials such as steel and cast iron.

Top face machining

| Material | S50C | |

|---|---|---|

| Cutting Efficiency | 840 cc/min | 735 cc/min |

| Tool | Φ200 mm face mill (10 teeth) | Φ160 mm face mill (8 teeth) |

| Cutting speed | 189 m/min | 220 m/min |

| D.O.C × Cutting width | 5 × 160 mm | 5 × 120 mm |

| Feedrate | 1053 mm/min | 1225 mm/min |

| Z- axis extension | 800 mm | |

Side surface machining

| Material | S50C | |

|---|---|---|

| Cutting Efficiency | 763 cc/min | 603 cc/min |

| Tool | Φ200 mm face mill (10 teeth) | Φ160 mm face mill (8 teeth) |

| Cutting speed | 189 m/min | 220 m/min |

| D.O.C × Cutting width | 5 × 145 mm | 4.1 × 120 mm |

| Feedrate | 1053 mm/min | 1225 mm/min |

| Z- axis extension | 800 mm | |

Structure and function for large-sized workpieces

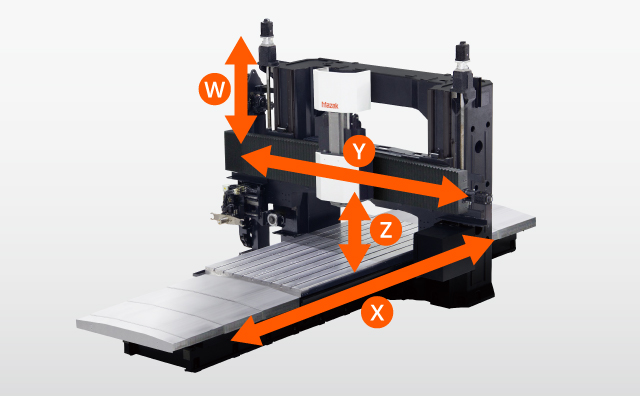

Powerful machining on all areas

Powerful machining can be performed by X-axis (table travel forward / backward) utilizing high rigidity roller guide, and slide ways on Y-axis (spindle head forward / backward) and Z-axis (spindle head travel up / down) with high rigidity and minimized vibration.

Highly rigid double column structure with columns connected by the cross beam.

It has sufficient rigidity against horizontal, vertical and torsional loads, ensuring stable machining accuracy.

W- axis controlled cross rail lift

Column height 1.65 m by simultaneous operation of ram (Z-axis stroke of 0.8 m) and cross rail (W-axis) for tall workpiece machining.

Equipped with touch screen CNC system MAZATROL SmoothG

MAZATROL SmoothG is a CNC system with a graphical user interface and touch screen for easy operation.