| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 1740 mm × 750 mm |

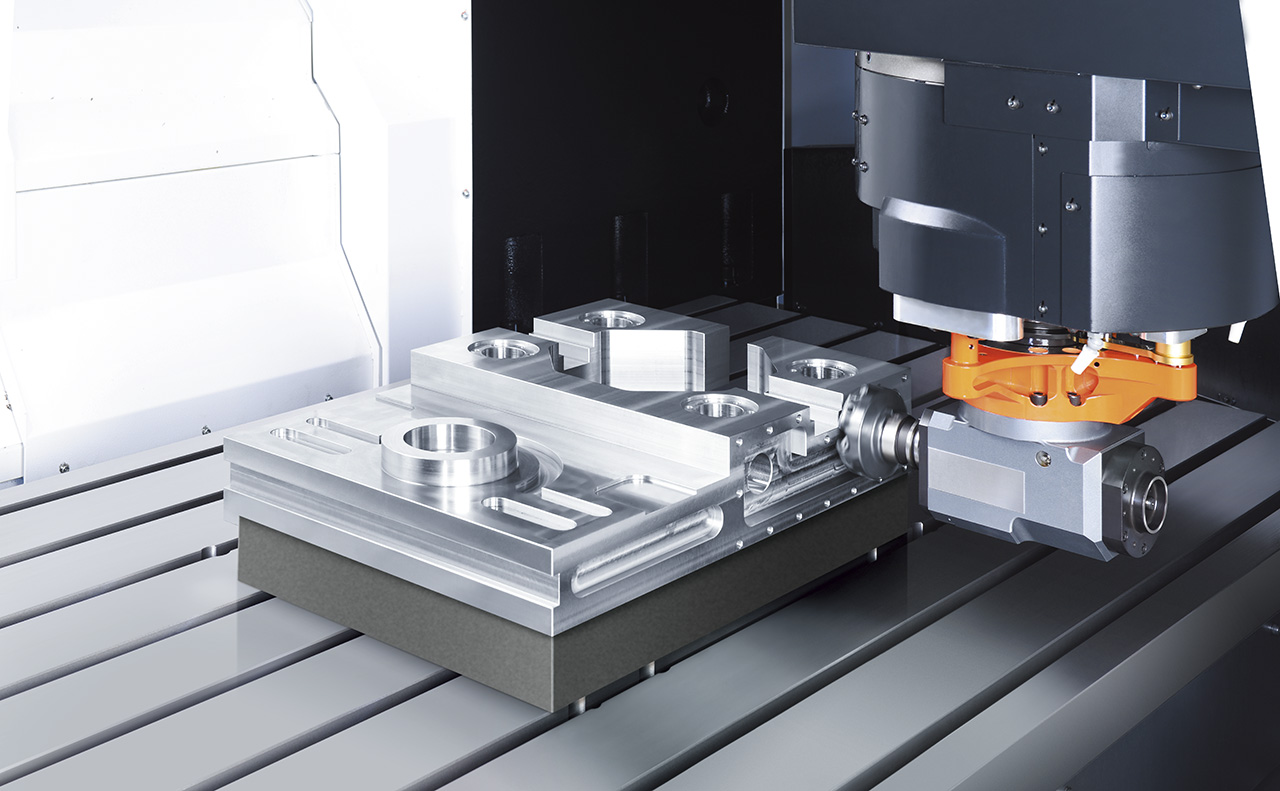

Vertical Machining Centers

FJV 5 Face

- Units and functions that make 5-surface machining accessible as standard equipment, achieving process integration

- Highly rigidity double column construction for high accuracy machining

- High-accuracy built-in motor spindle for high-efficiency machining

- Designed for high efficiency in machining large workpieces, with a wide lineup that can handle long shaft workpieces

- Equipped with touch screen CNC system MAZATROL SmoothG

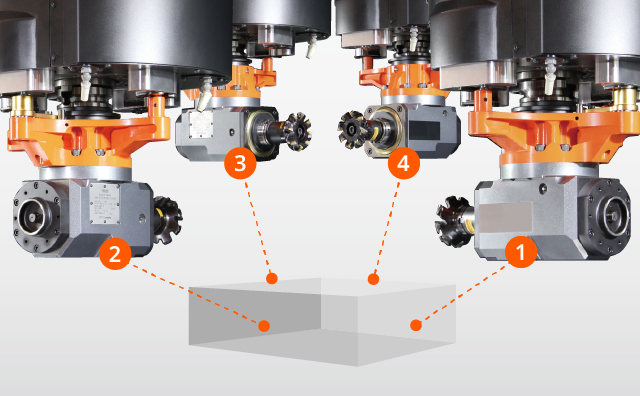

Units and functions that make 5-Face machining accessible as standard equipment

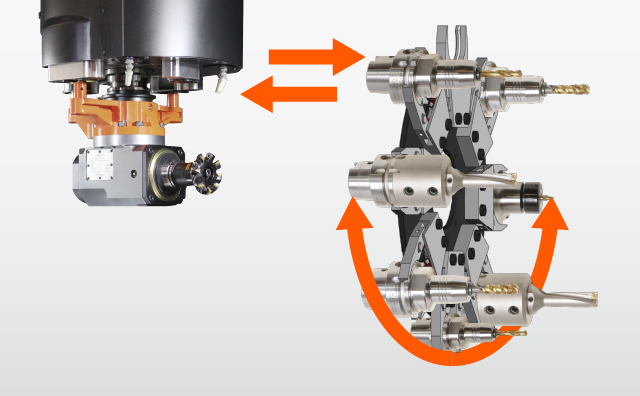

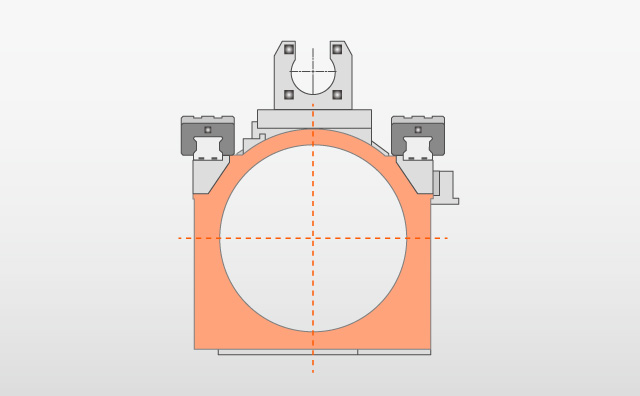

Four side face machining with one angle tool

The MAZAK 5 Face angle head is capable of powerful cutting with its unique hydraulic pressure clamping unit that provides strong fixation.

Wide angle head cutting range

Compact angle head reduces interference with workpiece for large machining area.

Enhanced versatility

The dedicated angle tool magazine has a storage capacity of 8 tools, which makes it possible to handle a wide variety of workpieces.

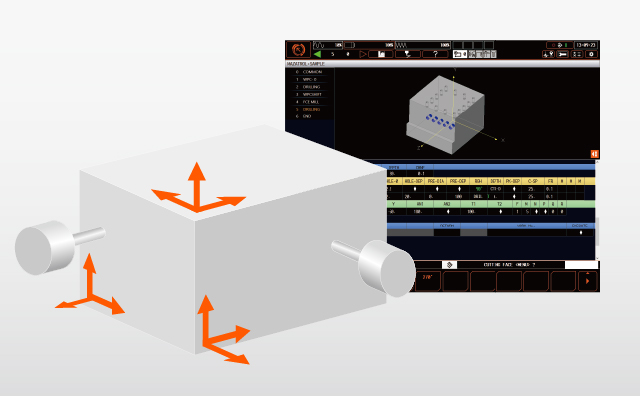

Simplified programming

The MAZATROL conversational program for 5-surface machining makes it easy to create programs for side face machining.

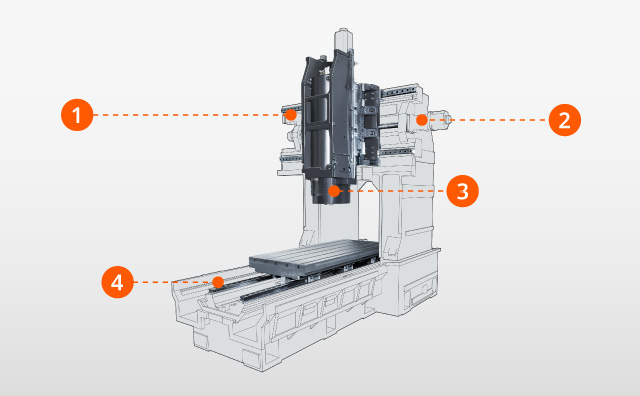

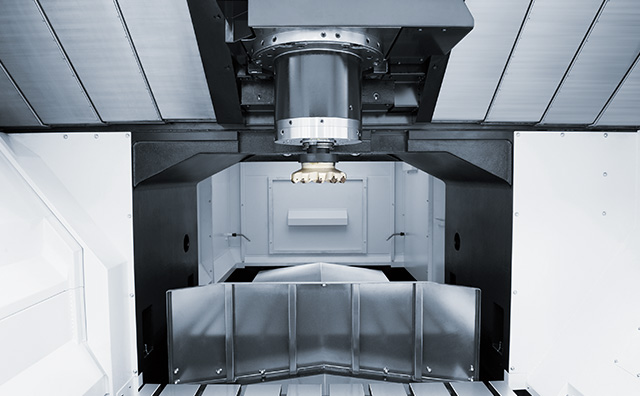

Double column machine construction provides high speed and high accuracy performance

- 1: |The double column construction delivers high accuracy machining over extended periods of operation

- 2: |High-accuracy positioning by ball screw and direct servo mounting

- 3: |Spindle temperature control prevents changes in machining accuracy

- 4: |Linear roller guides for high rigidity are used on all axes

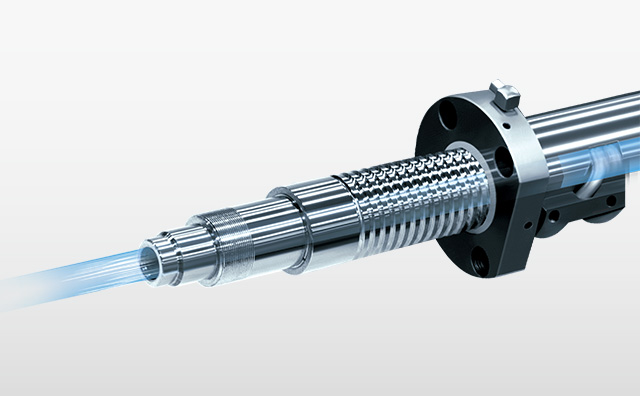

Ball screw core cooling

Temperature controlled cooling oil circulates through the ball screw cores. It ensures stable machining accuracy over extended periods of high speed operation.

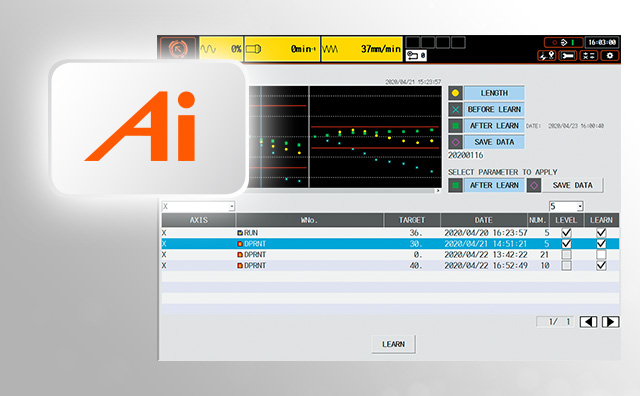

Ai Thermal Shield

Based on spindle speed and temperature of the machine, Ai Thermal Shield suppresses changes in the cutting edge position. It stabilizes continuous machining accuracy through meticulous machine control that takes into account temperature changes, machine position, coolant ON/OFF, and other factors.

High-accuracy built-in motor spindle for high-efficiency machining

Equipped with a built-in spindle, it eliminates the need for driving gear. It can reduce power loss and minimize vibration during high-speed operation to ensure exceptional surface finishes and maximum tool life.

High torque spindle and high speed spindle (BT40) are available as options

A 10000 min -1 standard spindle that can handle the machining of various materials such as cast iron, steel, and nonferrous metal , a 7000 min -1 high torque spindle (optional) that is effective for rough machining of steel and cast iron , and a BT40 18000 min -1 high-speed spindle (optional) that enables highly efficient machining of nonferrous metal and difficult machining material through high speed machining are available.

| Standard spindle | High torque spindle | High speed spindle(BT40) | ||

|---|---|---|---|---|

Max speed | 10000 min-1 | 7000 min-1 | 18000 min-1 | |

Motor output | 30 min. rating [40%ED] | 37 kW (50 HP) | 30 kW (40 HP) | 35 kW (47 HP) |

(Cont. rating) | 30 kW (40 HP) | 22 kW (30 HP) | 26 kW (35 HP) | |

Motor torque | 30 min. rating [40%ED] | 350 N・m | 442 N・m | 84 N・m |

(Cont. rating) | 239 N・m | 318 N・m | 57 N・m | |

Tool shank | BT50, | BT50*, | BT40*, |

- * Optional

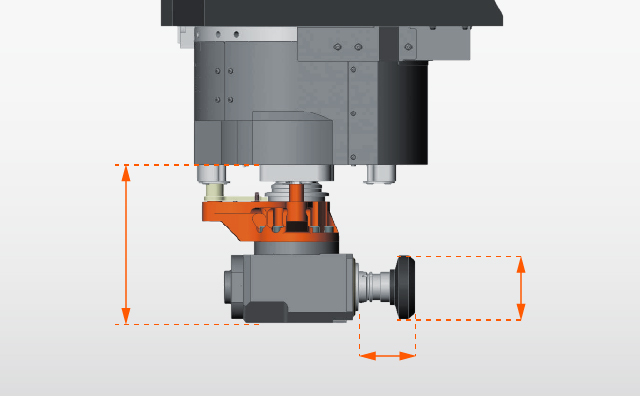

The compact spindle cartridge is designed for minimum interference.

This provides a wider machining area as well as the ability to use shorter tools for improved machining performance and accuracy.

Symmetrical spindle unit design

The symmetrical spindle unit design minimizes spindle displacement due to heat generation during machine operation.

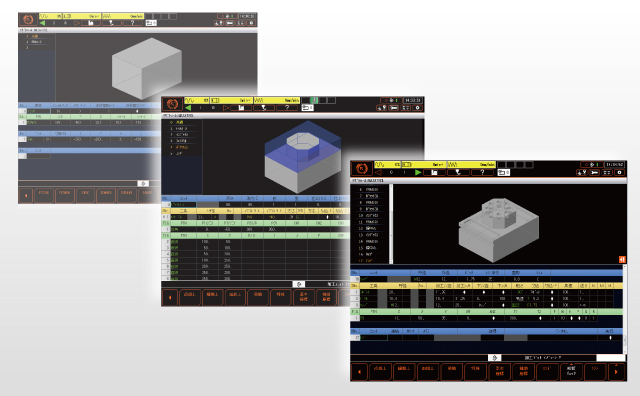

Equipped with touch screen CNC system MAZATROL SmoothG

MAZATROL SmoothG is a CNC system with a graphical user interface and touch screen for easy operation. Various functions are provided to help reduce programming time and improve machining efficiency.

QUICK MAZATROL

[Reduces program creation time]

Programs can be created while checking the machining shape and process, which helps prevent mistakes and shorten creation time. By touching the 3D model, you are instantly moved to the corresponding processing unit, making it easy to modify the program.

3D ASSIST

[Create programs directly from 3D CAD data]

Workpiece and coordinates data can be imported from 3D CAD data to a MAZATROL program. No coordinate value inputs are required. It can reduce input errors and time for program checking.

QUICK EIA

[Visualization of G code(EIA) programs]

By visualizing the G code(EIA) program, it supports checking and editing of small program increments. Visible search on touch screen can reduce the time for program checking.

Reference Video

FJV 5 Face-35/60

FJV 5 Face-35/80

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 2240 mm × 750 mm |

FJV 5 Face-35/120

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 3240 mm × 750 mm |

FJV 5 Face-60/80

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 2240 mm × 1250 mm |

FJV 5 Face-60/120

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 3000 mm × 1250 mm |

FJV 5 Face-60/160

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 4000 mm × 1250 mm |

Distance between columns: 2500 mm

FJV 5 Face-100/120

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 3000 mm × 2000 mm |

FJV 5 Face-100/160

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Table size | 4000 mm × 2000 mm |