| Chuck size | 6″ |

| Max. machining diameter | Φ350 |

| Max. machining length | 299 mm |

CNC Turning Centers

QTE

- Built-in motor for high cutting capacity

- Support of a wide range of specifications allows selection of models per production

- A variety of optional automation equipment can be chosen to increase productivity

- In-office digital setup will significantly reduce on-machine work*.

* Only MAZATROL SmoothEz is supported.

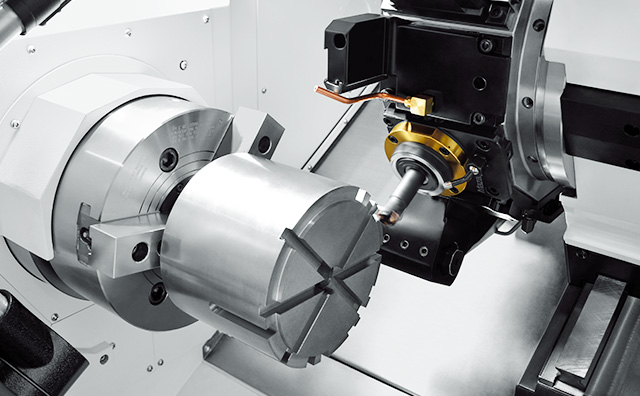

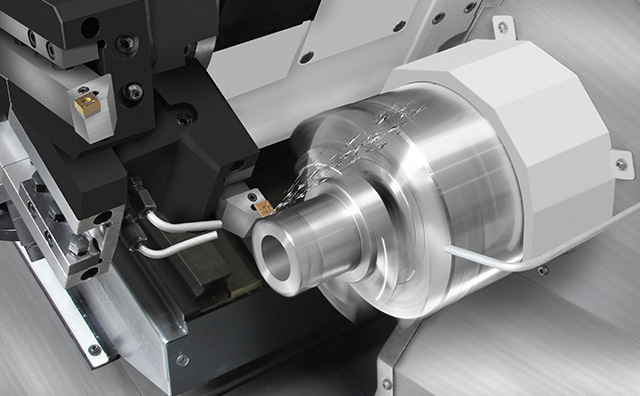

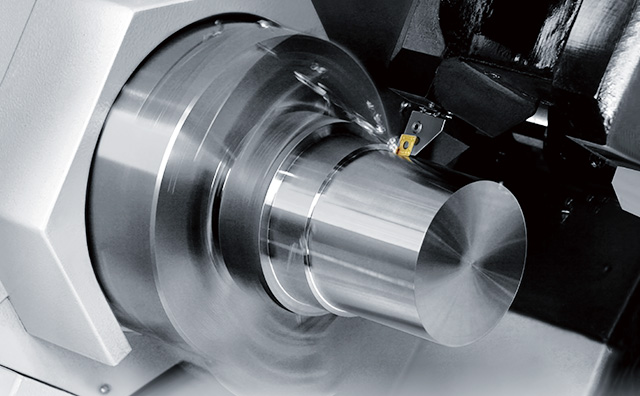

High-speed, high-torque, high-accuracy built-in motor spindle

High cutting capacity & maintenance free

The built-in motor spindle of the QTE series is designed to provide high torque even in the low-speed range, resulting in high cutting capacity. It is designed to have less causes of vibration as it has no gears or belts, so better roundness and surface accuracy can be acquired and power loss can be prevented. This simple structure leads to high reliability, as it does not require maintenance such as tension adjustment, which is needed for belt-driven models.

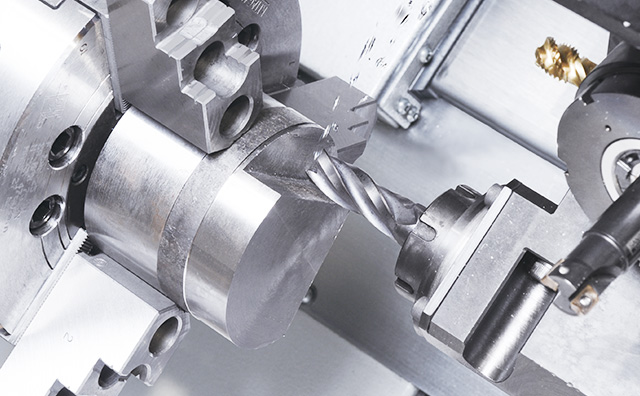

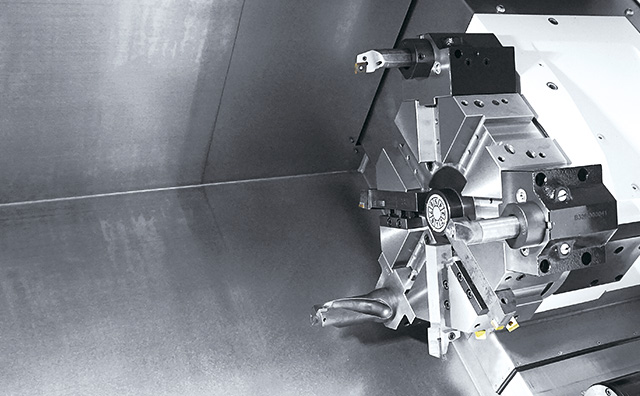

Selectable turrets

8 and 12 position drum turrets are available.

Non-lift rotary indexing for swift unclamping / clamping. The 25 mm × 25 mm tool shank ensures highly efficient machining.

| Supported models | Turret type |

| 100, 200, 300 | 8 Position Drum Turret |

| 12 Position Drum Turret (optional) | |

| 100M, 100MY, 100MS, 100MSY, 200M, 200MY, 200MS, 200MSY, 300M, 300MY, 300MS, 300MSY (Only MAZATROL SmoothEz is supported.) | 12 Position Drum Turret |

| 12 Position Drum Turret (24 position) (Optional) |

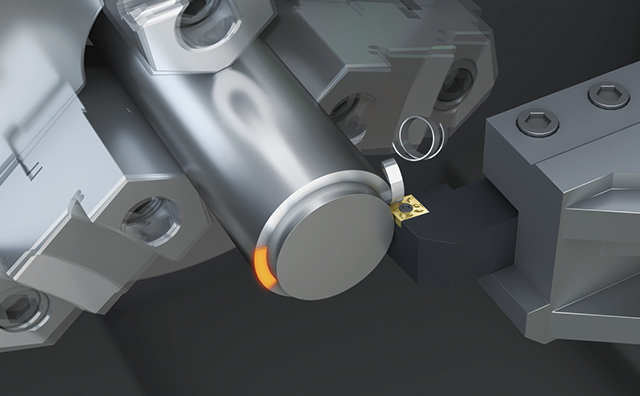

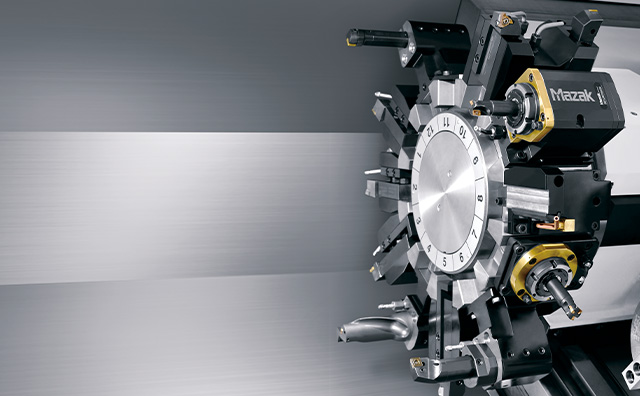

A wide range of specifications to suit your production style

A combination of turning, milling, Y-axis, and second spindle specifications can be used to select a model to suit production.

The machine sizes may be compact, but they can flexibly respond to the customization needs of our customers. Only MAZATROL SmoothEz is supported.

A variety of optional automation equipment can be chosen to increase productivity

Space-saving automation with collaborative robots "Ez LOADER series"

Ez LOADER, which uses a dedicated software, eliminates the need for complicated robot teaching tasks. It can be easily set up by anyone and also flexibly adapts to any changes in the floor layout.

Only MAZATROL SmoothEz is supported.

Gantry Loader: Automatic operation system for a wide range of applications

This system will easily make long-hour automatic operation possible with high speed / high accuracy workpiece loading/unloading. Different specification work loader hands and work conveyors are available to meet a wide range of production requirements.

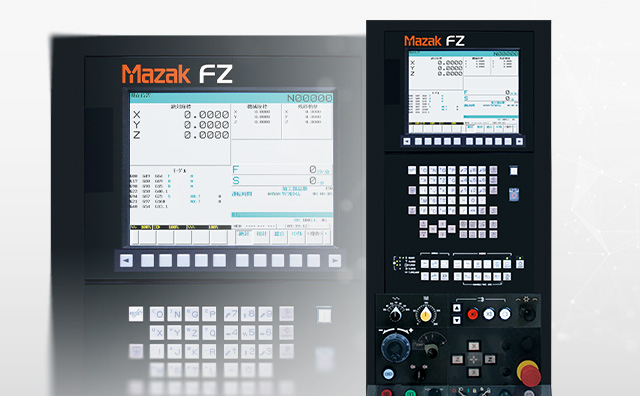

High-speed and high-accuracy simultaneous 4-axis CNC system

MAZATROL SmoothEz

The digital setup function can replicate the machine of your factory in the PC at your office. On the machine side, operation programs can be created while checking the workpiece shape and process, intuitively with touch panel controls.

MAZAK FZ

EIA / ISO programming functions are combined with MAZAK's unique and convenient menus for better usability.

MAZATROL DX transforms the manufacturing process

MAZATROL DX is a flat-rate digital service that revolutionizes the work process. It supports your work from automatic programming to setup work on the machine. In addition, it has essential functions for part machining, such as automatic quotation that automatically generates machining cost estimation.

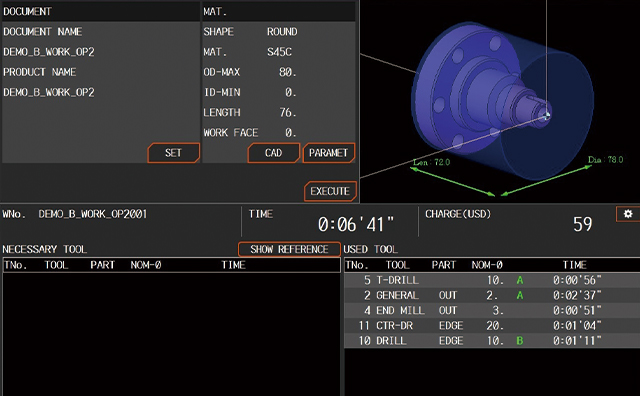

QUICK QUOTE (Automatic Quotation)

Quotations can easily and quickly be created from 3D models.

Machining cost, machining time and required tools are automatically calculated in about 30 seconds.

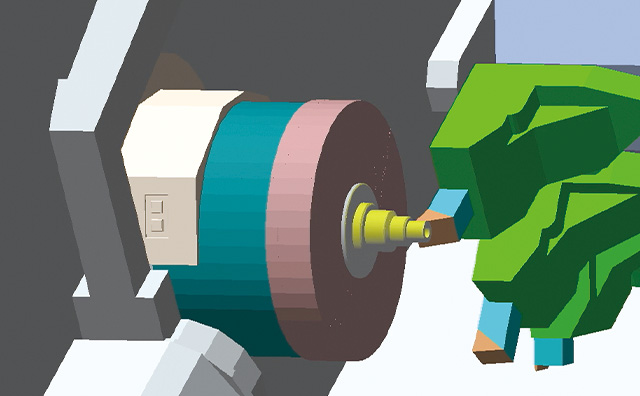

VIRTUAL MACHINING (Factory Simulation)

Digital setup in the office can greatly reduce on-machine work.

VIRTUAL MACHINING can accurately execute machining simulation under the same operating environment as the actual machine. This makes it possible for the user to confirm the machining shape and interference in advance, leading to highly productive operations from the beginning.

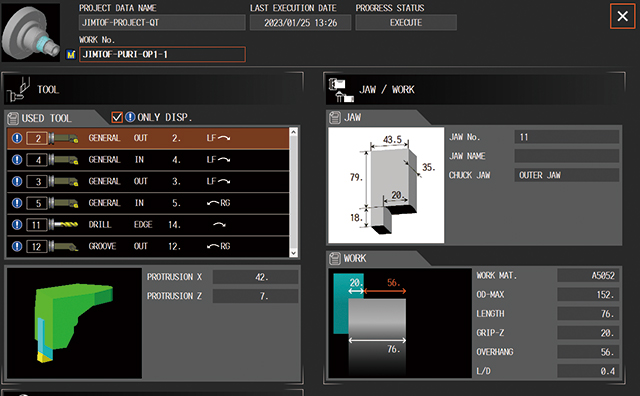

SETUP GUIDE (Tools・Fixtures・Materials Mounting / Automatic Measurement)

Automatic generation of setup instructions enables smooth installation and measurement work. It supports efficient, error-free on-machine setup.

QTE-100 SG

QTE-100M SG

| Chuck size | 6″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 554 mm |

QTE-100MS SG

| Chuck size | 6″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 596 mm |

QTE-100MSY SG

| Chuck size | 6″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 596 mm |

QTE-100MY SG

| Chuck size | 6″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 554 mm |

QTE-200 SG

| Chuck size | 8″ |

| Max. machining diameter | Φ350 |

| Max. machining length | 520 mm |

QTE-200M SG

| Chuck size | 8″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 1085 mm |

QTE-200MS SG

| Chuck size | 8″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 575 mm |

QTE-200MSY SG

| Chuck size | 8″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 575 mm |

QTE-200MY SG

| Chuck size | 8″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 1085 mm |

QTE-300 SG

| Chuck size | 10″ |

| Max. machining diameter | Φ390 |

| Max. machining length | 1063 mm |

QTE-300M SG

| Chuck size | 10″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 1054 mm |

QTE-300MS SG

| Chuck size | 10″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 539 mm |

QTE-300MSY SG

| Chuck size | 10″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 539 mm |

QTE-300MY SG

| Chuck size | 10″ |

| Max. machining diameter | Φ340 |

| Max. machining length | 1054 mm |