| Chuck size | 6″ |

| Max. Machining Diameter | Φ280 |

| Max. Machining Length | 409 mm |

CNC Turning Centers

QUICK TURN

- Built-in motor spindle and high rigidity machine construction provide unsurpassed performance

- Turning, milling, Y-axis and second spindle specifications designed to meet your production requirements

- Wide range of chuck size and center distance for both small and large machining

Evolving best-selling machines: QUICK TURN series

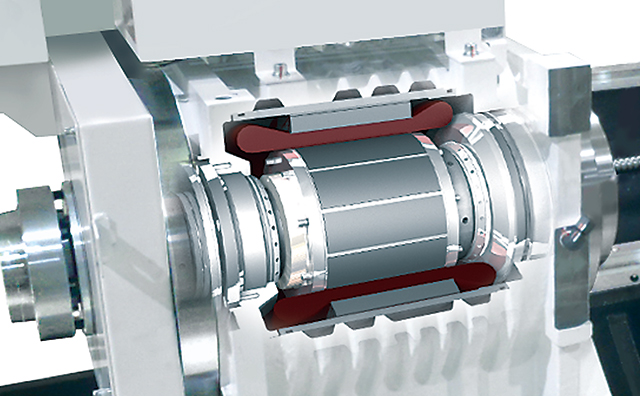

Spindle specifications to meet your machining requirements

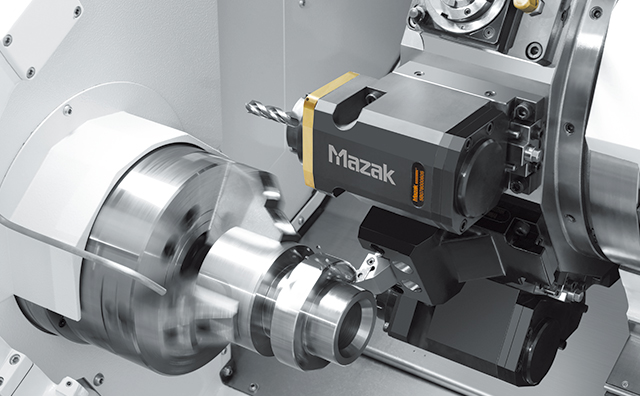

Built-in motor spindle, which is equipped on all models of series can perform heavy duty machining of difficult machining materials or ferrous metals, as well as high speed machining of non-ferrous materials such as aluminum. You can select the optimal spindle, including high speed and high torque specifications to meet your machining requirements.

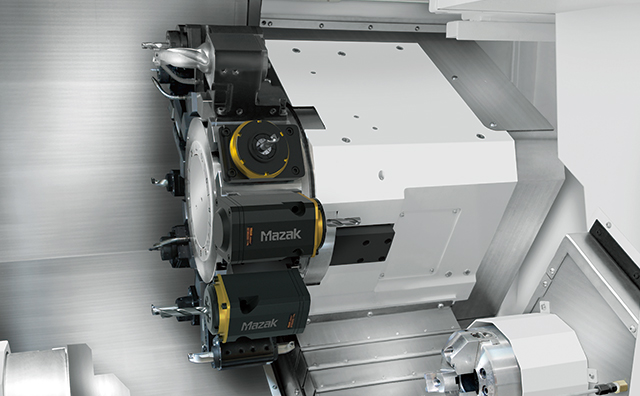

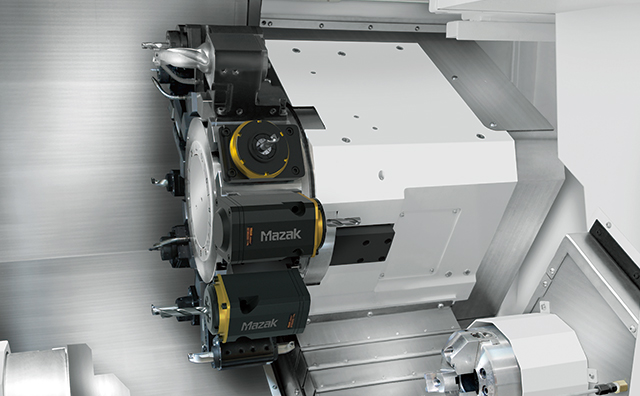

Continuous machining of the first and second process with a second spindle

The second spindle can also perform high-speed and high-quality turning and milling with its built-in motor spindle. C-axis indexing in 0.0001° minimum increments is standard. Contouring is optionally available.

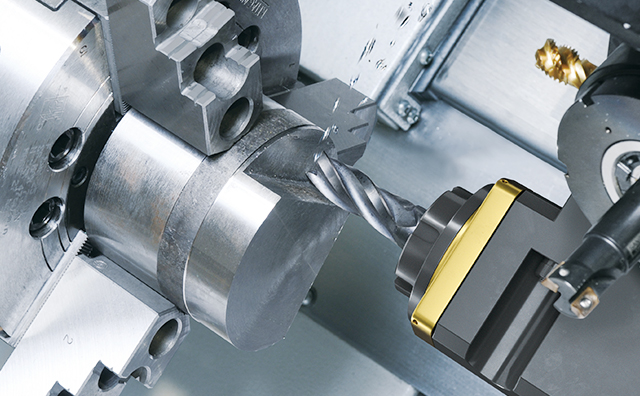

Y-axis machining for a wide range of applications

The long Y-axis stroke ensures high-accuracy and high-efficiency machining of complex workpieces. Multi-tasking machining of large workpieces is available in a compact machine.

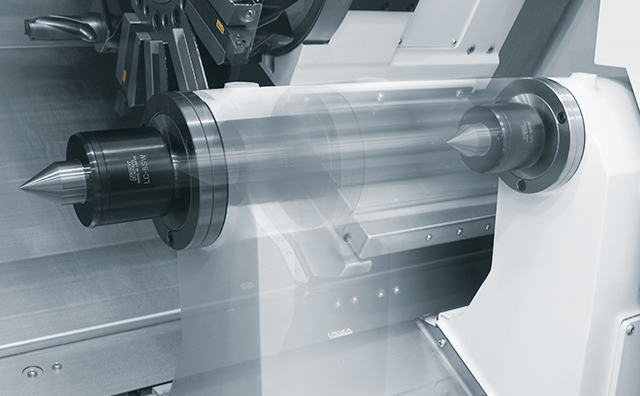

NC tailstock and steady rest

The operator can move the NC tailstock to the correct position and set the optimal thrust force, supporting high-accuracy machining of shaft workpieces. Together, NC tailstock and steady rest effectively suppress and maintain stability of long and small diameter workpieces and large-diameter workpieces machining.

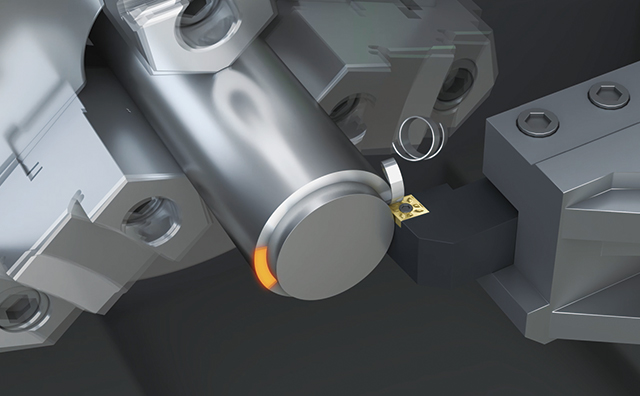

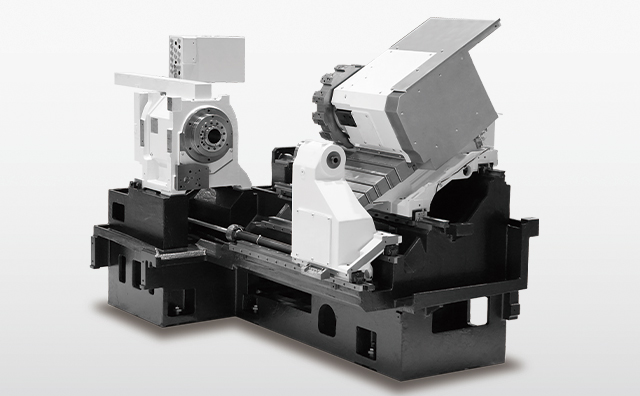

High rigidity construction

Machine construction and CNC technology provide even more stable machining accuracy

The rigid machine construction is designed to ensure high precision during heavy-duty machining and high-speed feedrates.

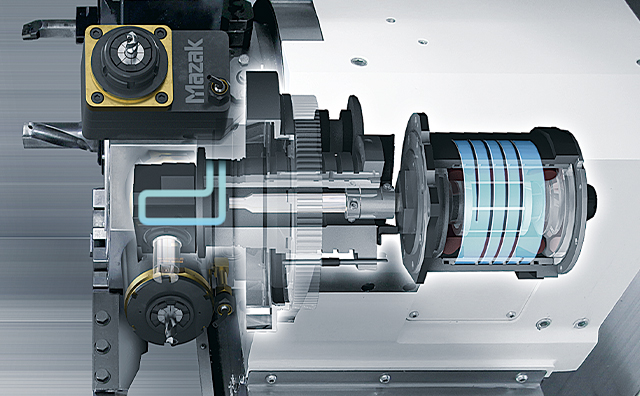

Without gear belt, built-in motor spindle minimizes vibration and improves roundness and machined surface accuracy.

Roller guides with excellent speed and durability are used on all axes.

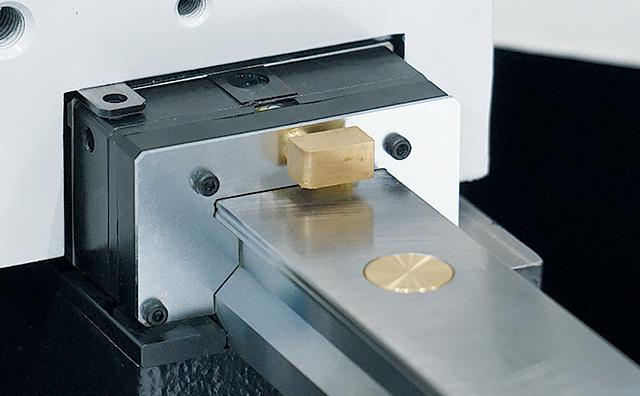

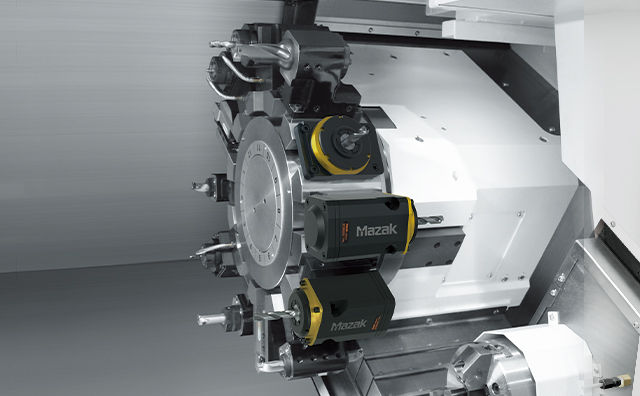

High speed drum turret with minimum interface

Three types of turrets are available for different applications

Depending on the model, 12 position drum turret, 16 position drum turret and 12 position drum turret (24 position) can be selected. Drum turret with minimum interface and non-lift rotary indexing perform high-speed clamping / unclamping. Tool holder can be selected between bolt-on or VDI.

High precision, high speed spindle

An integral motor is utilized for the turret milling spindle to minimize vibration for high accuracy. The motor unit is cooled to minimize heat generated during high-speed revolution.

A variety of optional automation equipment to increase productivity

Ez LOADER

Ez LOADER is a space-saving automation system with collaborative robots. With the specialized software, Ez LOADER eliminates tedious robot teaching tasks and can be easily set up by anyone.

Gantry Loader System

The unique structure of the gantry loader system provides unparalleled flexibility, enabling positioning conveyors on its left and right, adding measuring instruments, and connecting two machines. By adding automatic door and robot interfaces, the gantry loader can be retrofit on already installed machines.

High-speed and high-accuracy simultaneous 4-axis CNC system

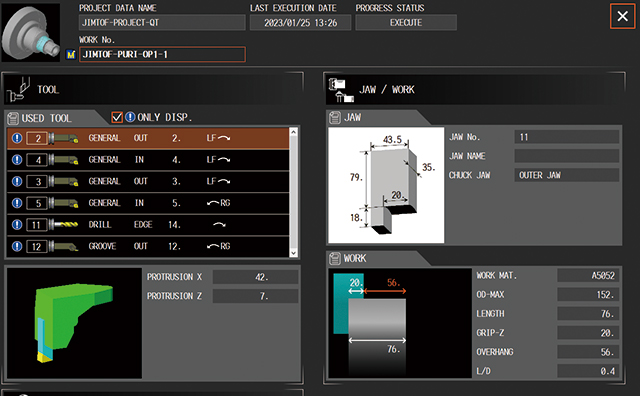

MAZATROL SmoothG

The touch panel is intuitive, and the 3D model display allows you to create programs while checking the machining shape and process. It prevents program errors and shortens program creation time. G code programming is also available.

MAZATROL DX transforms the manufacturing process

MAZATROL DX is a flat-rate digital service that revolutionizes the work process. It supports your work from automatic programming to setup work on the machine. In addition, it has essential functions for part machining, such as automatic quotation that automatically generates machining cost estimation.

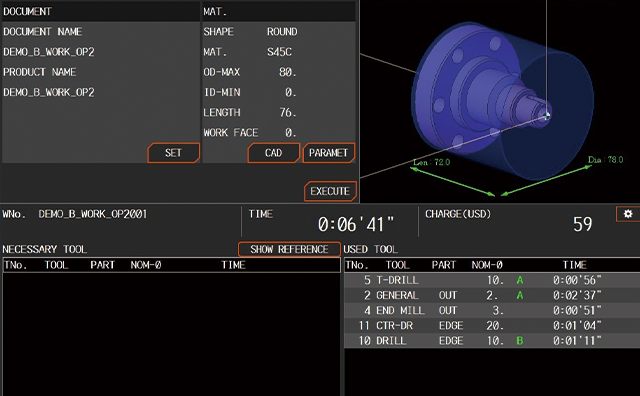

QUICK QUOTE (Automatic Quotation)

Anyone can easily and quickly create quotations from 3D models. Machining cost, machining time and required tools are automatically calculated in about 30 seconds. The program and other information used in the quotations is accumulated, so it can be used in later processes.

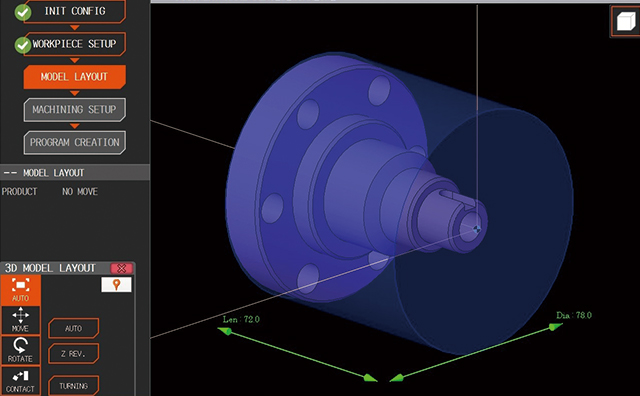

SOLID MAZATROL (Automatic / Conversational Programming)

MAZATROL programs are automatically generated from 3D models created with commercially available CAD/CAM software. An optimal program is generated by learning the appropriate machining pattern for the machining shape from programs created in the past.

SETUP GUIDE (Tools・Fixtures・Materials Mounting / Automatic Measurement)

Automatic generation of setup instructions enables smooth installation and measurement work. It supports efficient, error-free on-machine setup.

Reference Video

QUICK TURN 100MS

QUICK TURN 100MY

| Chuck size | 6″ |

| Max. Machining Diameter | Φ280 |

| Max. Machining Length | 340 mm |

QUICK TURN 100MSY

| Chuck size | 6″ |

| Max. Machining Diameter | Φ280 |

| Max. Machining Length | 409 mm |

QUICK TURN 200

| Chuck size | 8″ |

| Max. machining diameter | Φ350 |

| Max. Machining Length | 541mm / 1063 mm |

QUICK TURN 200MA

| Chuck size | 8″ |

| Max. Machining Diameter | Φ360 |

| Max. Machining Length | 535mm / 1055 mm |

QUICK TURN 200MB

| Chuck size | 8″ |

| Max. Machining Diameter | Φ380 |

| Max. Machining Length | 541 mm / 1047 mm |

QUICK TURN 200MY

| Chuck size | 8″ |

| Max. Machining Diameter | Φ380 |

| Max. Machining Length | 555 mm / 1020 mm |

QUICK TURN 200MSY

| Chuck size | 8″ |

| Max. Machining Diameter | Φ380 |

| Max. Machining Length | 578 mm |

Spindle 18.5 kW (25 HP)

Boring bar shank diameter Φ40 / Turning tool shank size 25 mm

QUICK TURN 250

| Chuck size | 10″ |

| Max. Machining Diameter | Φ380 |

| Max. Machining Length | 510.5 mm / 1032.5 mm |

QUICK TURN 250MA

| Chuck size | 10″ |

| Max. Machining Diameter | Φ360 |

| Max. Machining Length | 504.5 mm / 1024.5 mm |

QUICK TURN 250MB

| Chuck size | 10″ |

| Max. Machining Diameter | Φ276 |

| Max. Machining Length | 512 mm / 1018 mm |

QUICK TURN 250MY

| Chuck size | 10″ |

| Max. Machining Diameter | Φ276 |

| Max. Machining Length | 526 mm / 991 mm |

QUICK TURN 250MSY

| Chuck size | 10″ |

| Max. Machining Diameter | Φ276 |

| Max. Machining Length | 547 mm |

Spindle 26 kW (35 HP)

Boring bar shank diameter Φ50 / Turning tool shank size 25 mm

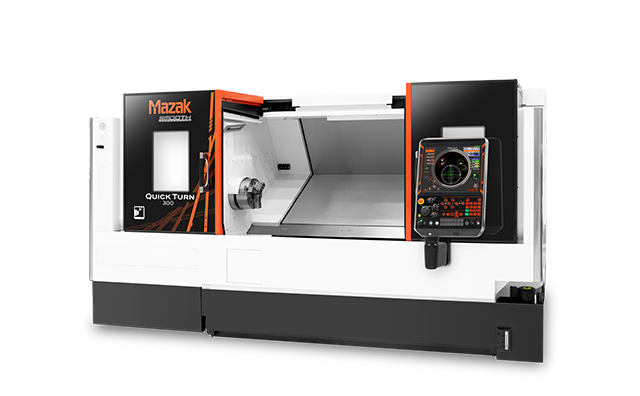

QUICK TURN 300

| Chuck size | 10″ |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 662 mm / 1282 mm / 1597 mm |

QUICK TURN 300MA

| Chuck size | 10″ |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 662 mm / 1282 mm |

QUICK TURN 300MB

| Chuck size | 10″ |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 652 mm / 1247 mm |

QUICK TURN 300MY

| Chuck size | 10″ |

| Max. Machining Diameter | Φ430 |

| Max. Machining Length | 658 mm / 1253 mm / 1593 mm |

Spindle 30 kW (40 HP)

Boring bar shank diameter Φ50 / Turning tool shank size 25 mm

QUICK TURN 350

| Chuck size | 12" |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 614 mm / 1234 mm / 1549 mm |

QUICK TURN 350MA

| Chuck size | 12" |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 614 mm / 1234 mm |

QUICK TURN 350MB

| Chuck size | 12" |

| Max. Machining Diameter | Φ420 |

| Max. Machining Length | 604 mm / 1199 mm |

QUICK TURN 350MY

| Chuck size | 12" |

| Max. Machining Diameter | Φ430 |

| Max. Machining Length | 610 mm / 1205 mm / 1545 mm |

Spindle 37 kW (50 HP)

Boring bar shank diameter Φ50 / Turning tool shank size 32 mm

QUICK TURN 400

| Chuck size | 12" |

| Max. Machining Diameter | Φ580 |

| Max. Machining Length | 1024 mm / 2074 mm |

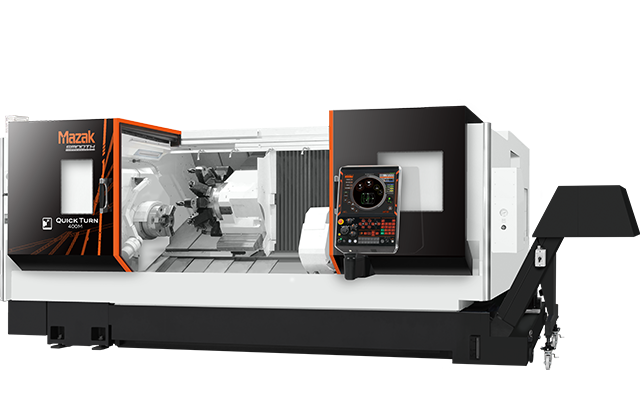

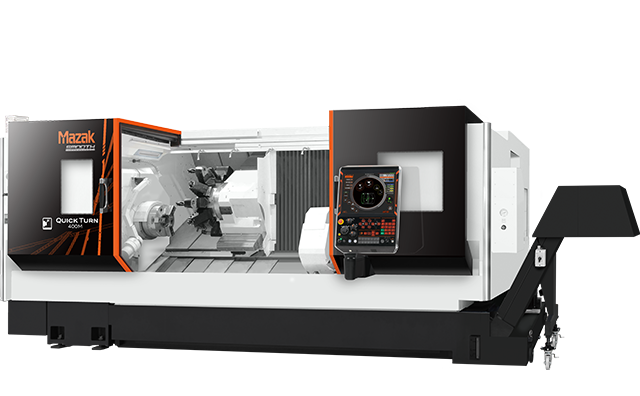

QUICK TURN 400M

| Chuck size | 12" |

| Max. Machining Diameter | Φ580 |

| Max. Machining Length | 996.5 mm / 2080.5 mm |

Photo: QUICK TURN 400M shown with optional equipment

Spindle 37 kW (50 HP)

Boring bar shank diameter Φ50 / Turning tool shank size 32 mm

QUICK TURN 450

| Chuck size | 18" |

| Max. Machining Diameter | Φ580 |

QUICK TURN 450M

| Chuck size | 18" |

| Max. Machining Diameter | Φ580 |