| Pallet size | 800 mm × 800 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ1450 mm × 1600 mm |

5-Axis Machining Centers

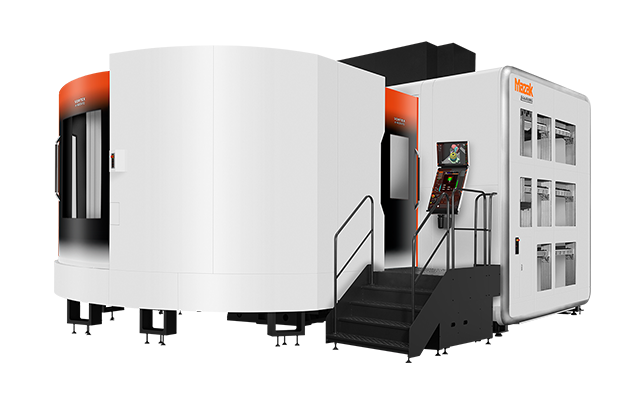

VORTEX e-V

- High-accuracy machining with double column structure

- A direct drive motor for table swivel axis (C-axis) is equipped for high-speed cutting feed during 5-axis machining

- Automated systems for diverse workpieces and production volumes

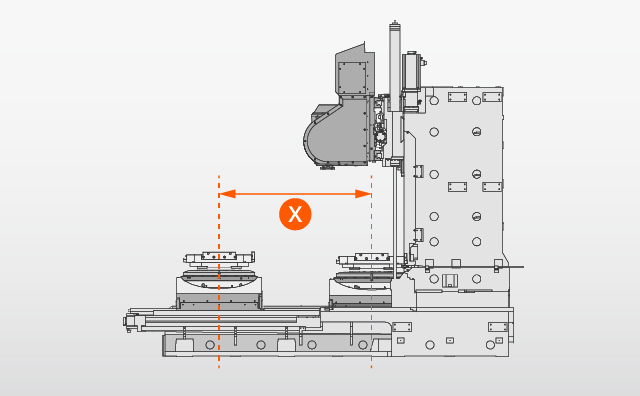

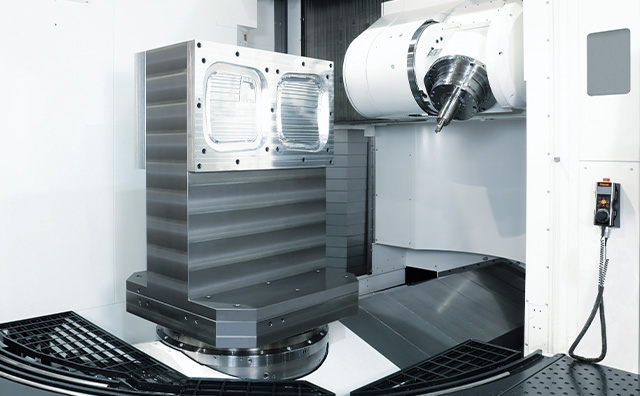

Wide range milling with double column structure

Double column construction suitable for top face machining of large workpiece

By utilizing double column structure together with long axes strokes, top face milling can be performed with only linear X- and Y-axis positioning, resulting in stable machining accuracy and higher productivity.

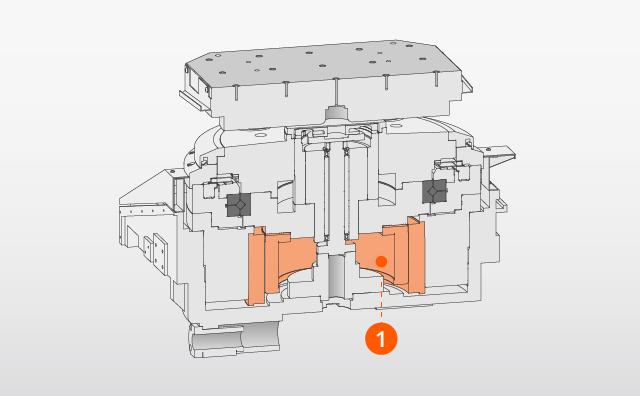

Direct drive motor for high-speed cutting feed in 5-axis machining

High-speed, high-precision table (C-axis)

The table uses a direct drive motor for high speed C-axis feed. Since a direct drive motor directly delivers power to C-axis with less power loss, high speed feed is ensured with 5-axis control for enhanced productivity.

Automated systems for diverse workpieces and production volumes

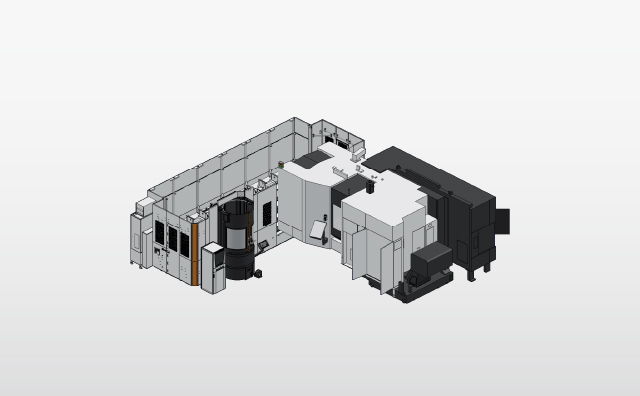

PALLETECH HIGH-RISE SYSTEM (2 levels)

- *Compatible only with VORTEX e-1250V/8

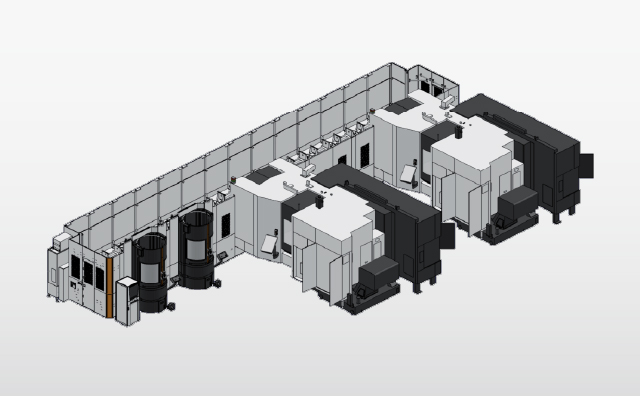

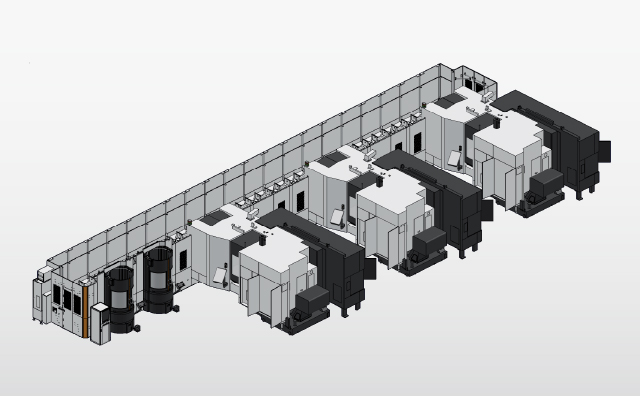

PALLETECH MANUFACTURING CELL (1 level)

- Flexible system expansion is possible in response to changes of production volume

- Different types of Mazak machines can be flexibly integrated into the system

- Flexible linkage with peripheral equipment and systems that increase the rate of automation of long-time automatic operations and machining processes

- Example: PALLETECH MANUFACTURING CELL (1 level)

- Step 1

- Step 2

- Step 3

*The starter set is the required configuration of PALLETECH MANUFACTURING CELL (1 level)

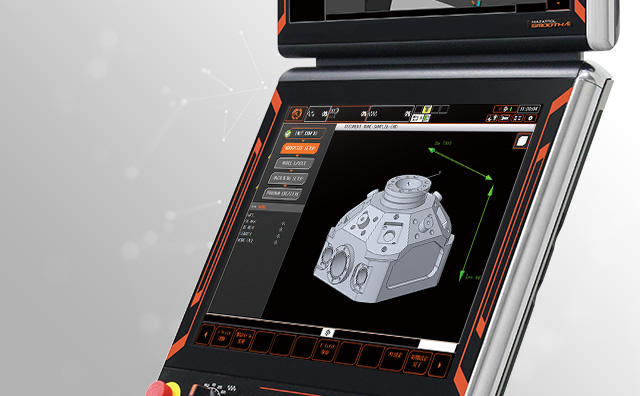

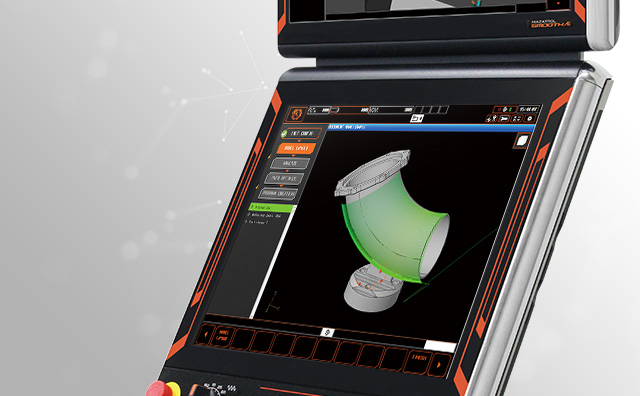

CNC System: MAZATROL SmoothAi

Innovative MAZATROL CNC system for higher productivity

MAZATROL SmoothAi provides unsurpassed productivity through even faster and higher precision control while elevating your production with AI and digital twin technology and advanced automation capabilities.

MAZATROL DX

The same environment as the actual MAZATROL SmoothAi machine can be reproduced on an office PC using digital twin technology.

Multiple virtual machines can be built, which can make programming, editing, simulation, and function analysis possible.

The setting data of the actual machine is synchronized, which ensures the accuracy of the digital setup.

- AI Programming

- High speed simulation

- Processing analysis / optimization

Automation

Software development and functions to support automation

VORTEX e-1250V/8

VORTEX e-1250V/8S

| Pallet size | 800 mm × 800 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ1500 mm × 1655 mm |

VORTEX e-1600V/10

| Pallet size | 1000 mm × 1000 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ2050 mm × 1600 mm |

VORTEX e-1600V/10S

| Pallet size | 1250 mm × 1250 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ2300 mm × 1684 mm |