| Pallet size | Φ500 mm × 400 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ500 mm × 350 mm |

5-axis Machining Centers

VARIAXIS i

- Multi-face machining and simultaneous 5-axis machining with one chucking

- Wide variety of table sizes, spindles, and automation systems

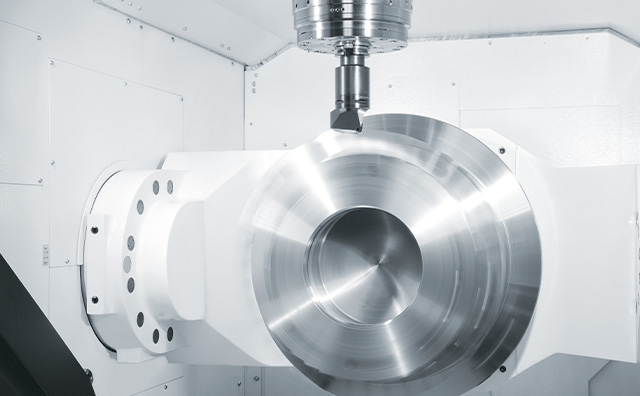

- Turning capability for further process integration (i-700T, i-800T, i-1050T)

Machining from raw material to final product in just one machine

Higher productivity with process integration by turning and milling

- Reduction of setup process

- Significant reduction in production lead time

- Reduction of fixture and equipment costs

- Reduction of machine installation space

- Minimization of cumulative errors by process integration to ensure high accuracy

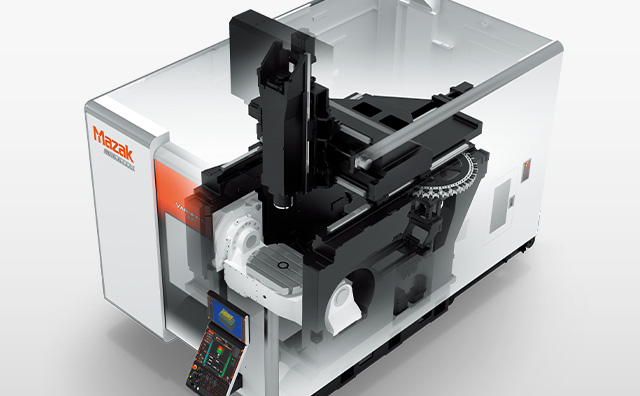

High rigidity for long-term high-accuracy machining

Full gantry construction without overhang

Machine construction was designed utilizing FEM analysis. Vibration is minimized during acceleration / deacceleration to ensure high accuracy machining stability. (Note: The construction of VARIAXIS i-500 is different.)

Built-in motor spindle

Built-in motor minimizes vibration during high speed operation. For high accuracy machining, temperature controlled cooling oil is circulated around the spindle bearings and headstock to minimize any thermal change to the spindle.

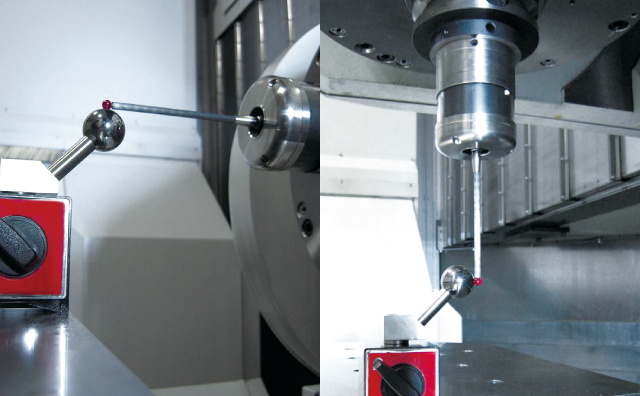

High-accuracy 5-axis calibration MAZA-CHECK

Position misalignment and incline of the rotary axes can automatically be measured and compensated to realize high accuracy 5-axis machining. The centers of rotation of both the C- and A-axis can be automatically measured and compensated.

Automated system best suited for multi-product processing

2-pallet changer

The next workpiece can be setup while machining is in progress, improving productivity.

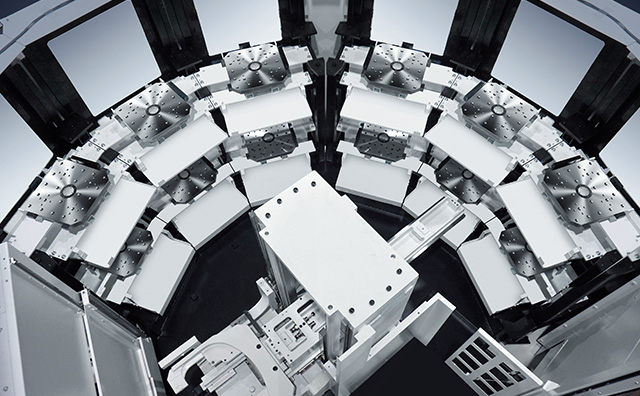

MPP (MULTI PALLET POOL)

MPP (MULTI PALLET POOL) is a space-saving multi-stage pallet stocker system developed in response to the growing demand for automation. As the most suitable automation system for multi-product machining, the system dramatically improves productivity.

PALLETECH SYSTEM

The PALLETECH system improves productivity by making effective use of machines and fixtures with minimal capital investment and by improving system uptime.

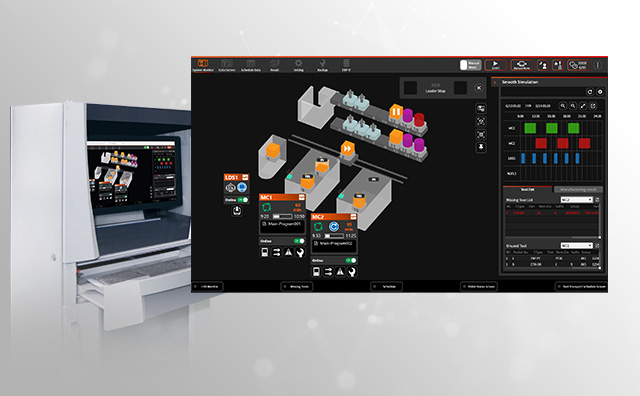

PMC NEO

PMC NEO is management software for automated operation of PALLETECH system. With a redesigned graphical user interface and the adoption of 3D images, it has become easier to grasp the operational status of the system. The convenience of data input and registration has also been improved.

By displaying work and tool lists in chronological order, the Setup Guide function assists the operator.

Reference Video

VARIAXIS i-500

VARIAXIS i-600

| Pallet size | Φ600 mm × 500 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ700 mm × 450 mm |

VARIAXIS i-1050

| Pallet size | Φ1050 mm × 800 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ1250 mm × 900 mm |

VARIAXIS i-700T

| Pallet size | Φ630 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 18000 min-1 (rpm) |

| Max. workpiece size | Φ850 mm × 500 mm |

VARIAXIS i-800T

| Pallet size | Φ800 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ1000 mm × 375 mm Φ800 mm × 500 mm |

VARIAXIS i-1050T

| Pallet size | Φ1050 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 10000 mm-1 (rpm) |

| Max. workpiece size | Φ1250 mm × 900 mm |