| Tool shank | BT50 |

| Max. workpiece size | Φ1250 mm × 1250 mm |

| Max. spindle speed | 500 min-1 (rpm) |

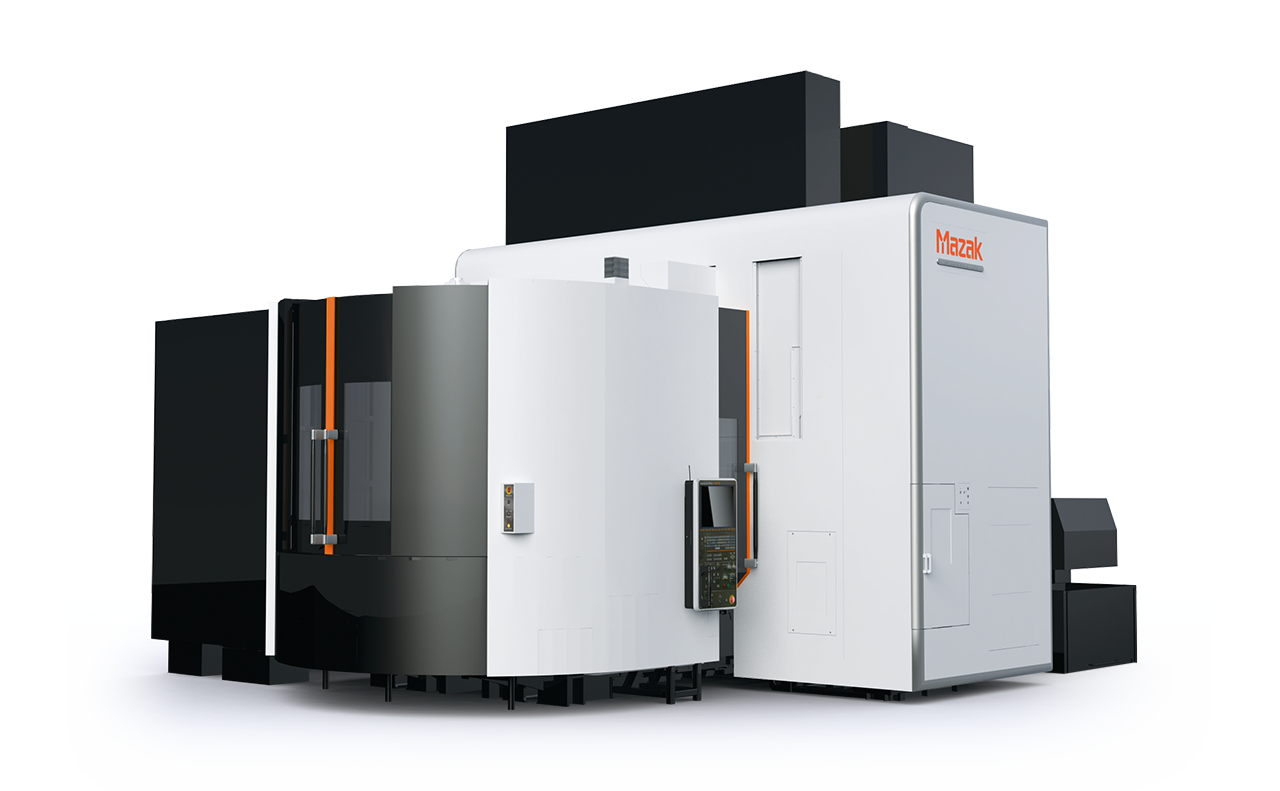

Multi-Tasking Machines

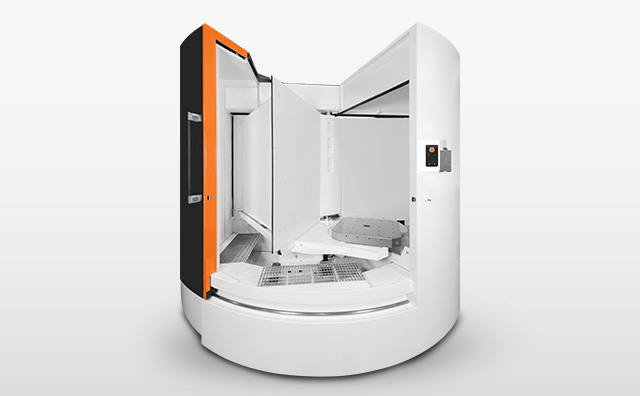

INTEGREX e-RAMTEC

- Long X-axis and Y-axis strokes for high-accuracy machining of large parts

- Ram spindle for deep inner diameter boring and milling

High-accuracy machining with double column construction

Double column construction suitable for top face machining of large parts

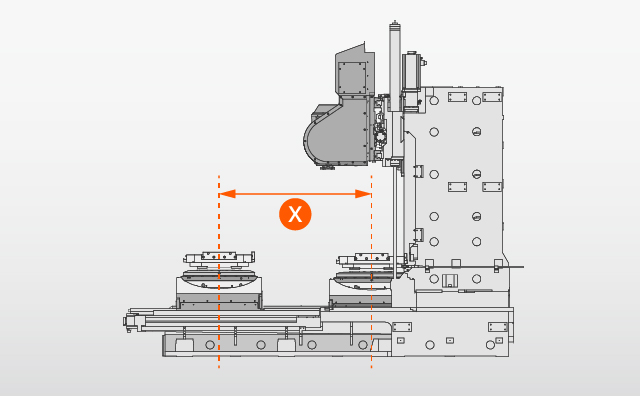

By taking advantage of the double column construction and the long X-axis stroke beyond the milling spindle, top face milling can be performed with only linear X- and Y-axis positioning, resulting in stable machining accuracy and higher productivity.

X-axis stroke

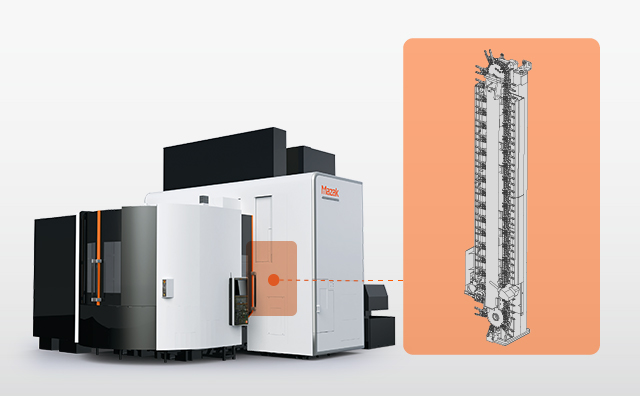

Ram spindle mounted on 5-axis controlled vertical multi-tasking machines

Ram spindle

The ram spindle with a vertical stroke of 900 mm, mounted next to the milling spindle, performs deep inner diameter turning and milling that cannot be machined even with long tools, thus achieving further process integration.

Automatic ram spindle tool changer

A dedicated tool magazine is prepared to hold 40 turning and milling tools. The machine can handle a wide variety of machining and change to spare tools during long-term machining.

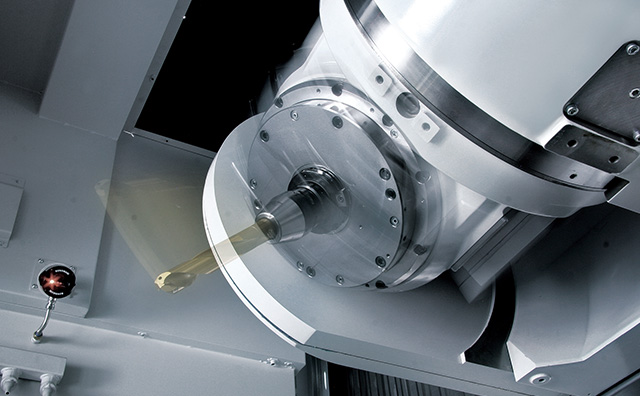

Milling spindle

Built-in motor milling spindle is both compact and high power. In addition to the 10,000 min-1 standard spindle for various materials, the lineup includes a 5,000 min-1 optional spindle suitable for high-torque machining of difficult-to-machine materials and a 15,000 min-1 optional spindle that enables high-speed machining.

* Option

The B-axis (travel: 150°) is indexed and positioned with high precision over the long term using a roller gear cam which eliminates backlash.

Turning spindle

The high power, high-torque turning spindle performs efficient rough machining and finishing of large-diameter, heavy-duty workpieces. In addition, the C-axis can position in 0.0001° increments and ensures high-accuracy machining.

Higher productivity in multi-product machining

2-pallet changer for efficient setup

2-pallet changer promptly replace pallets loaded with heavy workpieces. Setup station rotates with high precision. In addition, the optional workpiece centering tool supports the operator to smoothly perform the alignment work required for turning.

* Option

TOOL HIVE*

TOOL HIVE is a rack-type magazine that combines storage for over 180 tools with space-saving design. Loading/unloading and data editing of tools are available by the dedicated operation panel TOOL HIVE TERMINAL, reducing setup time. Storage can be expanded after the first installation.

* Option

INTEGREX e-RAMTEC V/8

INTEGREX e-RAMTEC V/10

| Tool shank | BT50 |

| Max. workpiece size | Φ2000 mm × 1440 mm |

| Max. spindle speed | 300 min-1 (rpm) |

INTEGREX e-RAMTEC V/12

| Tool shank | BT50 |

| Max. workpiece size | Φ2350 mm × 1800 mm |

| Max. spindle speed | 250 min-1 (rpm) |