| Pallet size | 1250 mm × 1000 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 min-1 (rpm) |

| Max. workpiece size | Φ2350 mm × 1800 mm |

Horizontal Machining Centers

HCN-Q

- Deep boring of large workpieces

- Rigid machine structure for heavy-duty machining

- Designed for high speed and high accuracy performance

Capable of boring deep, large-diameter holes in large parts up to 10 tons

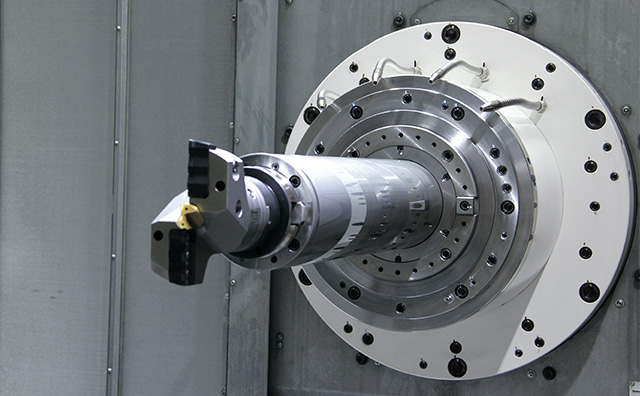

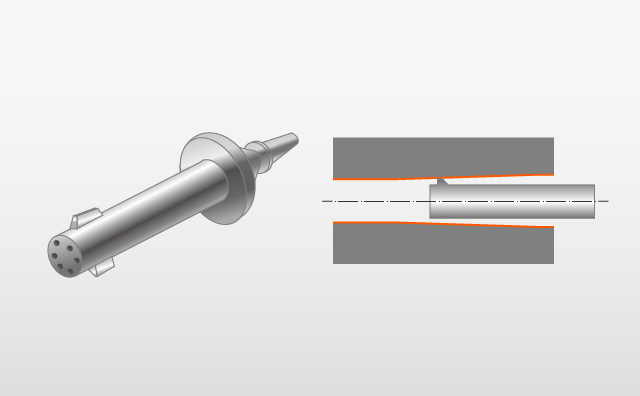

Quill spindle for higher machining efficiency

- Spindle bearing inside diameter Φ180 mm. The multiple-row front spindle bearings provide the rigidity required for heavy duty machining.

- Quill diameter Φ130 mm / core cooling available (option)

- High output, high torque gearless built-in motor spindle (Standard equipment)

Quill Spindle

| Maximum Speed | 3000 min-1 |

| Output | AC 45 kW (60 HP) [40% ED] |

| AC 37 kW (50 HP) [Cont. rating] | |

| Maximum Torque | 1849 N・m (188.4 kgf・m) [40% ED] |

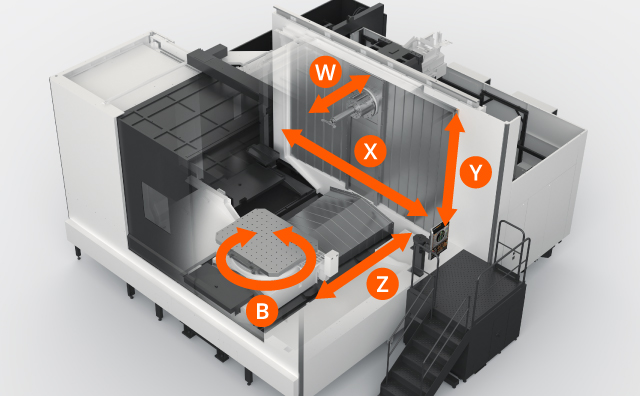

Rigid base, column and high accuracy linear guides

Y-axis twin ball screw

The spindle head is driven by 2 ball screws in the Y-axis.

Vibration is minimized to ensure accuracy stability during high speed machining.

Linear roller guides utilized on all axes

Linear roller guides on the X-, Y- and Z-axis are utilized by the HCN-Q series in order to provide high accuracy and heavy duty machining.

Variety of Attachment*

Optional automatic attachment changer increases parts processing flexibility through the use of various special operation attachments

* Compatible with HCN-12500Q, 16000Q, 16800Q (optional)

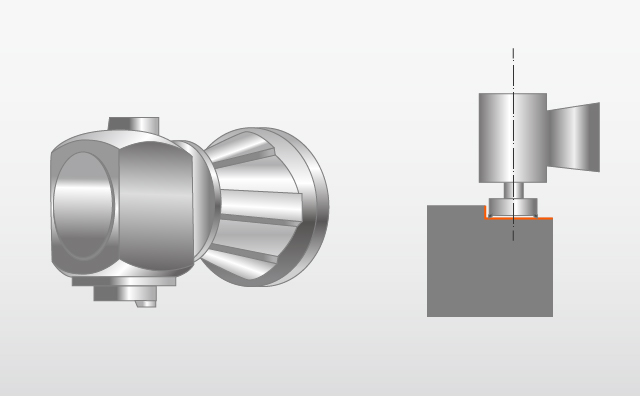

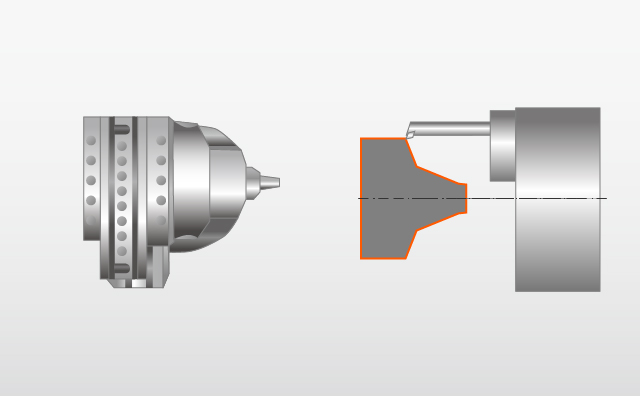

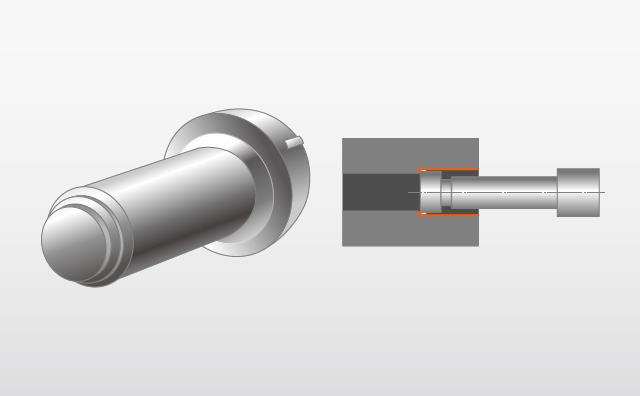

U-axis boring attachment

Angle attachment

U-axis facing attachment

Snout attachment

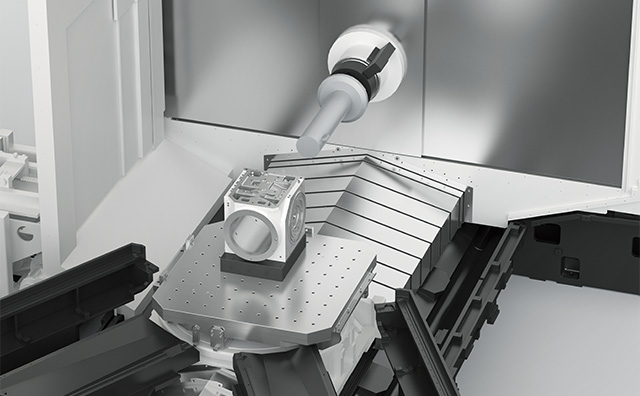

Automation available from single machine to a large-scale system

2-pallet changer*

The 2-pallet changer allows the unloading of a finished workpiece and the loading of the next workpiece during the machining of the current workpiece. It can handle heavy workpieces, and its stable, long-term operation improves productivity.

* Compatible with HCN-12500Q, 16000Q, 16800Q

PALLETECH SYSTEM*

This automated system makes it possible to achieve long-term unmanned operation of large workpieces, significantly shortening lead times. It is designed for convenient system expansion after the initial installation to easily respond to increased production requirements in the future.

* Compatible with HCN-12500Q, 16000Q, 16800Q (optional)

Reference Video

Photo: HCN-16000QS

Maximum workpiece height: 1800 mm

HCN-12500Q

HCN-12500QS

| Pallet size | 1250 mm × 1000 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 min-1 (rpm) |

| Max. workpiece size | Φ2350 mm × 1800 mm |

Maximum workpiece height: 2000 mm

HCN-16000Q

| Pallet size | 1600 mm × 1250 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 min-1 (rpm) |

| Max. workpiece size | Φ3000 mm × 2000 mm |

HCN-16000QS

| Pallet size | 1600 mm × 1250 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 mm-1 (rpm) |

| Max. workpiece size | Φ3000 mm × 2000 mm |

Maximum workpiece height: 2400 mm

HCN-16800Q

| Pallet size | 1600 mm × 1250 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 mm-1 (rpm) |

| Max. workpiece size | Φ3000 mm × 2400 mm |

HCN-16800QS

| Pallet size | 1600 mm × 1250 mm |

| Tool shank (standard) | BT50 |

| Max. spindle speed | 3000 min-1 (rpm) |

| Max. workpiece size | Φ3000 mm × 2400 mm |