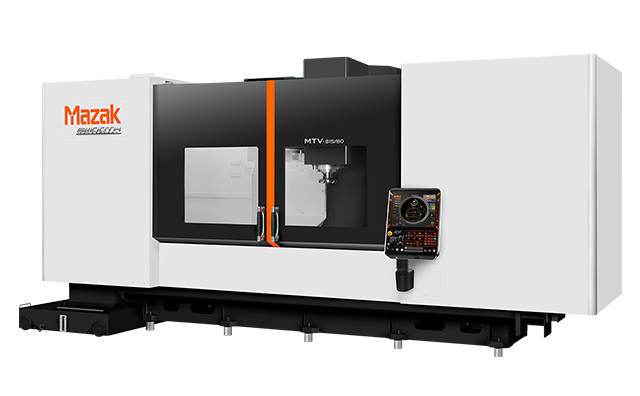

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 1300 mm × 550 mm |

Vertical Machining Center

MTV

- Equipped with BT50 high-torque spindle. Demonstrates high productivity from heavy-duty cutting of long and heavy workpieces to machining of difficult-to-machine materials.

- Highly rigid machine structure with back and forth column and horizontal table travel system

- Tables with a wide machining area and outstanding load capacity

- Equipped with touch panel CNC system MAZATROL SmoothG

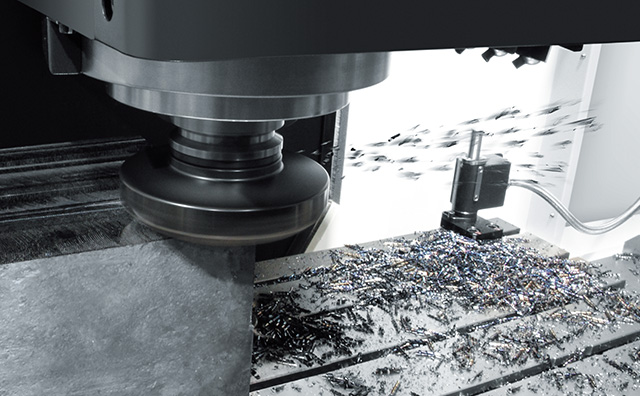

BT50 high-torque spindle for hard materials

The MTV series spindles have high torque and quick start-up even in the low RPM range, and perform high machining capacity for powerful cutting of heavy, long, and large workpieces. For applications such as steel and difficult-to-machine materials that require machining torque.

| Spindle output* | Max. torque* | |

|---|---|---|

| 6000 min-1 standard spindle | 18.5 kW | 759 N・m |

| 6000 min-1 high torque spindle | 26.0 kW | 1067 N・m |

- * |The figures are based on 40% ED for both spindle output and torque.

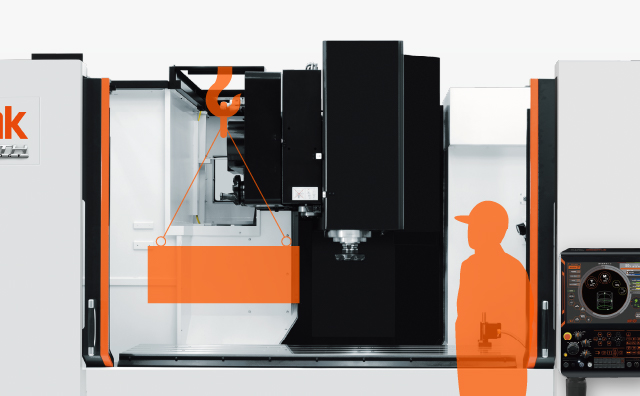

Machine design for ease of operation and maintenance

The ergonomic design emphasizes operability based on the operator's point of view.

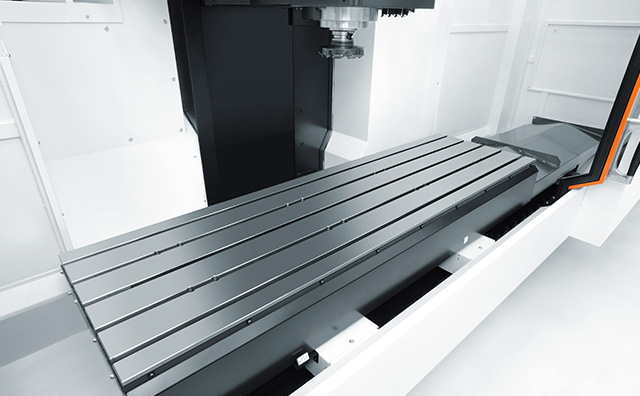

Machine structure with excellent workability and good crane access

The column moves back and forth, providing good access to the table and making it easy to check tools and tips. Good crane access from the ceiling for easy loading and unloading of heavy loads.

Tables with a wide machining area and outstanding load capacity

MTV series tables with a large machining area, can be used for machining tall workpieces and long materials.

Wide range of table lineup

You can select the optimum table size according to your workpiece size.

| Table size | Max. workpiece dimensions | Maximum loading capacity | |

|---|---|---|---|

| MTV-515/40 | 1300 mm × 550 mm | 1300 mm × 550 mm × 680 mm | 1500 kg |

| MTV-655/60 | 1740 mm × 650 mm | 1740 mm × 650 mm × 770 mm | 2000 kg |

| MTV-655/80 | 2240 mm × 650 mm | 2240 mm × 650 mm × 770 mm | 2500 kg |

| MTV-815/80 | 2240 mm × 810 mm | 2240 mm × 810 mm × 870 mm | 3000 kg |

| MTV-815/120 | 3240 mm × 810 mm | 3240 mm × 810 mm × 870 mm | 3000 kg |

Equipped with touch screen CNC system MAZATROL SmoothG

MAZATROL SmoothG is a CNC system with a graphical user interface and touch screen for easy operation. Various functions are provided to help reduce programming time and improve machining efficiency.

QUICK MAZATROL

Mazatrol conversational program using everyday language allows you to easily create and edit programs by simply inputting dimensions. Even inexperienced operators can create programs quickly.

Smooth Machining Configuration

SMC is equipped with functions to easily adjust machine characteristics related to machining time, smooth finished surfaces, and accuracy according to the workpiece and machining method.

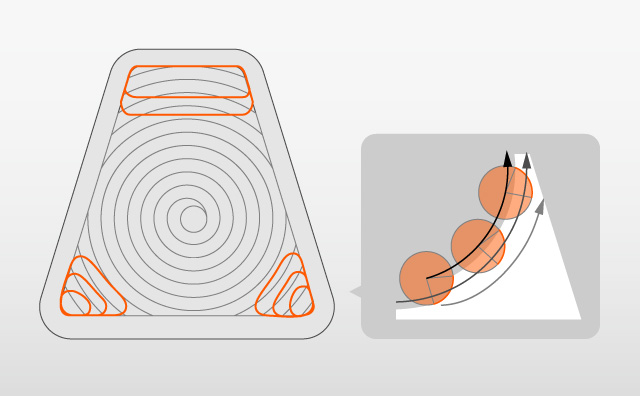

Pocket milling cycle

Easily and automatically generates a tool path that maintains a constant contact angle between the tool cutting edge and the workpiece during pocket milling. It reduces fluctuations in machining load, thereby extending tool life and improving machining efficiency.

MTV-515/40

MTV-655/60

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 1740 mm × 650 mm |

MTV-655/80

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 2240 mm × 650 mm |

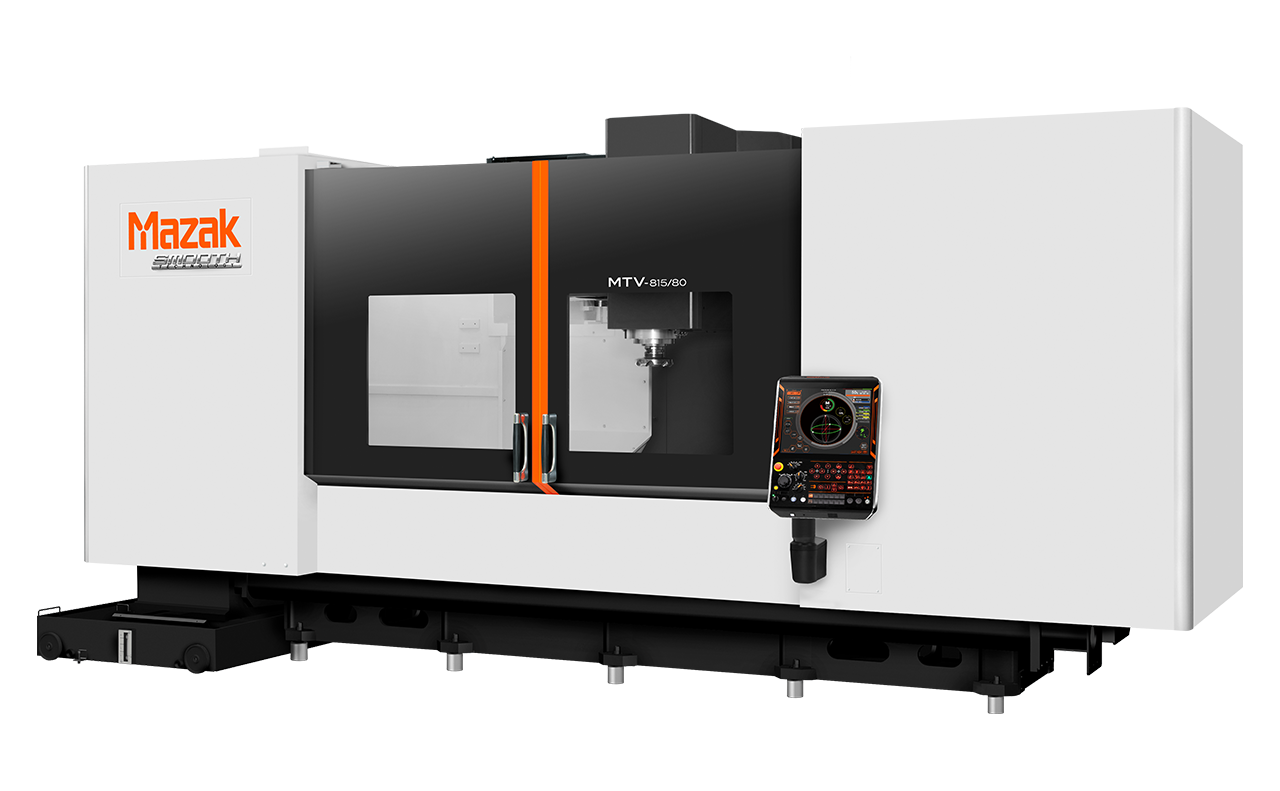

MTV-815/80

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 2240 mm × 810 mm |

MTV-815/120

| Tool shank (standard) | BT50 |

| Max. spindle speed | 6000 min-1 (rpm) |

| Table size | 3240 mm × 810 mm |