| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Table size | 900 mm × 460 mm |

Vertical Machining Centers

VCN

- Built-in motor spindle with enhanced cutting performance

- Spindle rigidity and best balance of rigid machine structure for heavy-duty machining capacity

- Large machining area and table size with extended Y-axis travel

- Machine specifications and functions for stable high-accuracy machining

Maximum 54% increase in machining capacity, BT40 spindle as standard equipment

The 18.5 kW, 12000 min-1 specification standard spindle on the VCN-460 and VCN-600 has achieved 41% improvement in machining capacity for Φ80 mm face mills and 54% improvement for Φ50 mm end mills, compared to the conventional machines. In addition, Φ50 mm U-drilling and M30 tapping are available. An optional 18,000 min-1 spindle is available for aluminum machining and metal mold machining.

| Φ80 mm face mill | Machining Capacity | Workpiece material: S45C | ||

| Conventional spindle | 361 cm3 | 41%UP | ||

| new spindle | 508 cm3 | 41%UP | ||

| Φ50 mm end mill | Machining Capacity | Workpiece material: S45C | ||

| Conventional spindle | 418 cm3 | 54%UP | ||

| New spindle | 645 cm3 | 54%UP | ||

High-performance built-in motor spindle with 30 kW and BT50 output

VCN-535C and VCN-700D are available in a total of four spindle types: a standard 8000 min-1 spindle for various materials ranging from steel to aluminum, and high-speed and high-torque specifications. It can be used for a wide range of applications from high speed machining to heavy cutting.

| Model | Spindle | |||

|---|---|---|---|---|

| 7000 min-1 | 8000 min-1 | 10000 min-1 | 18000 min-1* | |

| VCN-535C | ● | 〇 | ||

| VCN-700D | 〇 | ● | 〇 | 〇 |

●: Standard, 〇: Option, -: Not supported *BT40 only

Spindle rigidity and best balance of rigid machine structure

3D design with structural analysis

Using CAD FEA, the main machine components such as the bed and column are designed to minimize distortion. Compared to the conventional model, distortion on the column caused by heat displacement has been improved by 40%.

The low-vibration, high-performance spindle reduces thermal expansion by adopting outer cylinder cooling with machine temperature synchronization. Stable machining accuracy can be obtained.

* VCN-460

* Photo shows VCN-460.

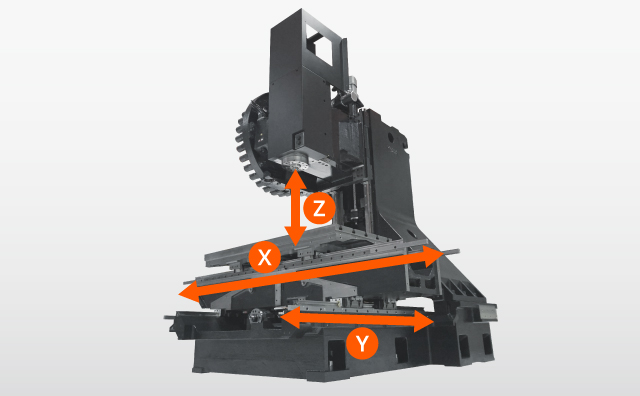

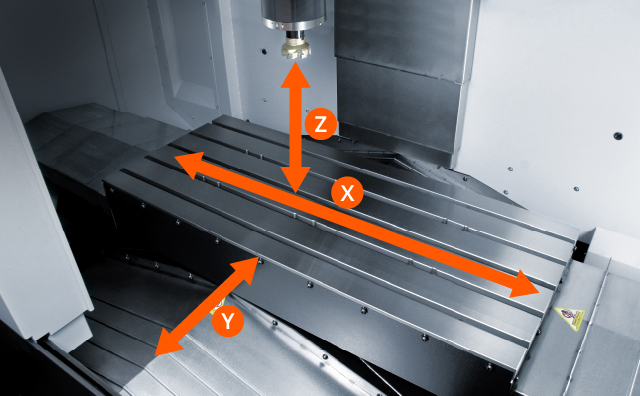

Large machining area and table size

The VCN series tables provide a large machining area with extended Y-axis stroke. Large fixtures and workpieces can be mounted. The optimal table size can be selected according to the workpiece.

| Y-axis stroke | Table size | Max. workpiece dimensions | |

| VCN-460 | 460 mm | 900 mm × 460 mm | 900 mm × 460 mm × 570 mm |

| VCN-600 | 600 mm | 1300 mm × 600 mm | 1740 mm × 650 mm × 770 mm |

| VCN-535C | 530 mm | 1300 mm × 550 mm | 1300 mm × 550 mm × 570 / 770* mm |

| VCN-700D | 700 mm | 1740 mm × 700 mm | 1740 mm × 700 mm × 770 mm |

* Maximum workpiece dimensions for high column specifications.

CNC systems that can be selected according to ease of use and processing applications

CNC system can be selected from standard models to high speed and high precision control functions. Equipped with "Quick Mazatrol" for enhanced Mazatrol programming.

Reference Video

VCN-460

VCN-600

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Table size | 1300 mm × 600 mm |

VCN-535C

| Tool shank (standard) | BT50 |

| Max. spindle speed | 8000 min-1 (rpm) |

| Table size | 1300 mm × 550 mm |

VCN-700D

| Tool shank (standard) | BT50 |

| Max. spindle speed | 8000 min-1 (rpm) |

| Table size | 1740 mm × 700 mm |