| Clamp interface | HSK-A100 holder |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ350 mm × 315 mm |

5-Axis Machining Centers

VARIAXIS i-300 AWC

- Compact workpiece stocker and tool magazine enable continuous machining

- Standard Smooth AWC software for Auto Work Changer management and operation

- High-speed and high-precision machining of complex components

A compact automation system for efficient machining of a wide variety of small lot parts

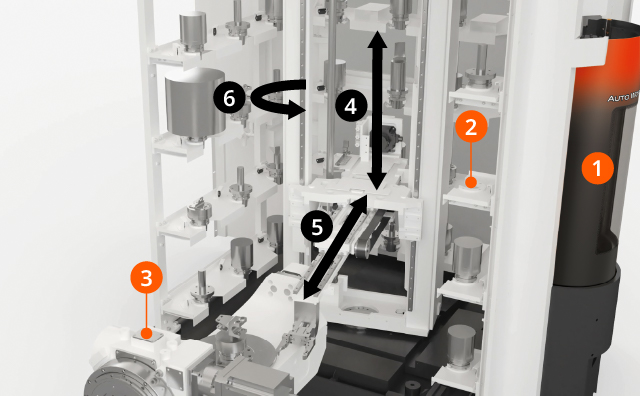

Automatic Work Changer (AWC)

Materials stored in the work stocker are carried into the machine, and after machining is complete, they are removed and stored in the work stocker. According to the set schedule, materials are loaded and unloaded in sequence for continuous machining.

- 1: Loading station

- 2: Work stocker

- 3: Table

- 4: Loader vertical movement

- 5: Loader horizontal movement

- 6: Loader rotation

Selectable work stocker

After the initial installation, the work stocker can be expanded from 32 to 40 work stockers, depending on the production situation.

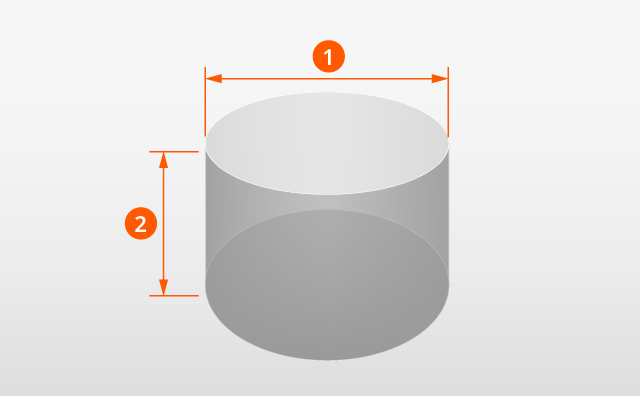

Transportable workpiece specifications

Max. workpiece size

1: Diameter: Φ350 mm

2: Height: 315 mm

The maximum weight is 65 kg including the work holder.

Smooth AWC

Smooth AWC is a setup management and automatic operation software for the VARIAXIS i-300 AWC incorporated in the CNC system, MAZATROL SmoothAi.

- 19 inch touch panel for intuitive operation

- The system monitoring screen displays the status of the entire AWC system

- Easy operation even when machining different workpieces with the same fixture on the work holder

- Setup instructions are displayed during automatic operation

You can switch between the CNC screens on this machine to operate it.

- 1: Schedule

- 2: Missing and unnecessary tools list

- 3: Production schedule

- 4: Setup work instructions

- 5: Alarm display

Compact tool magazine with large tool storage capacity

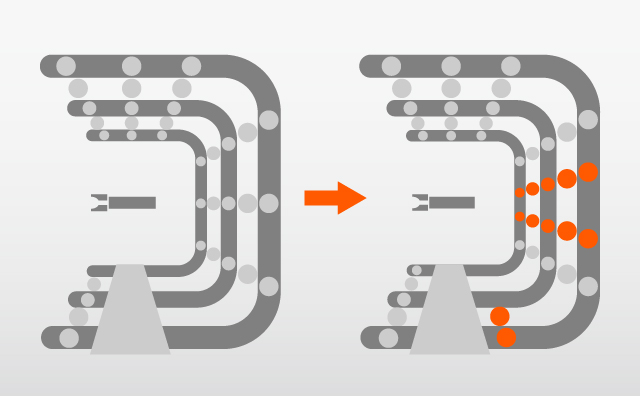

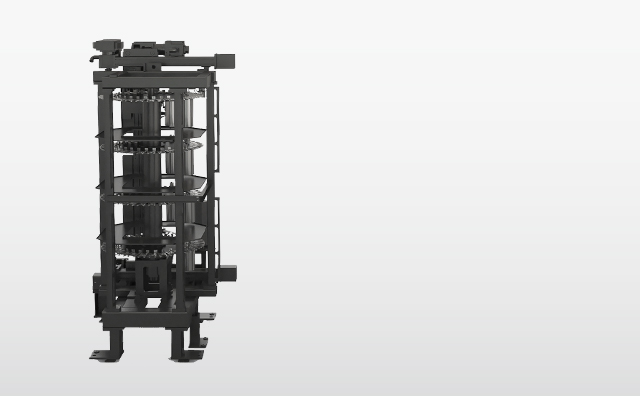

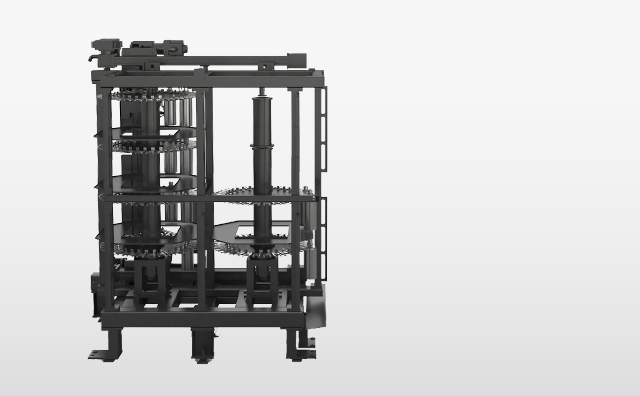

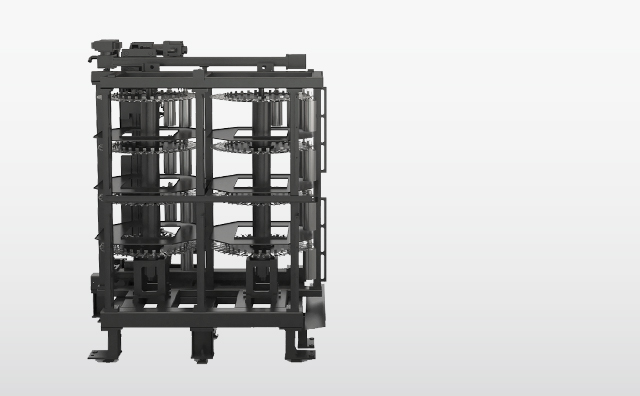

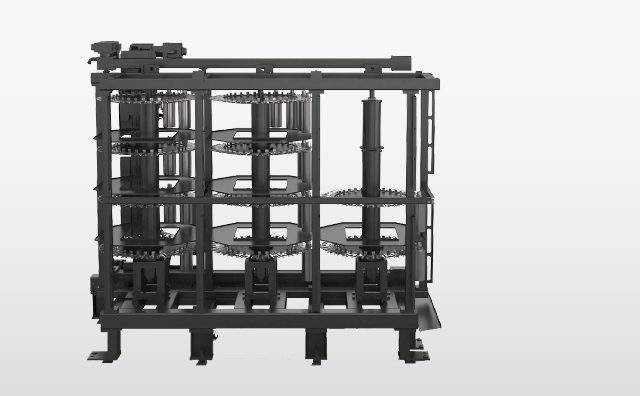

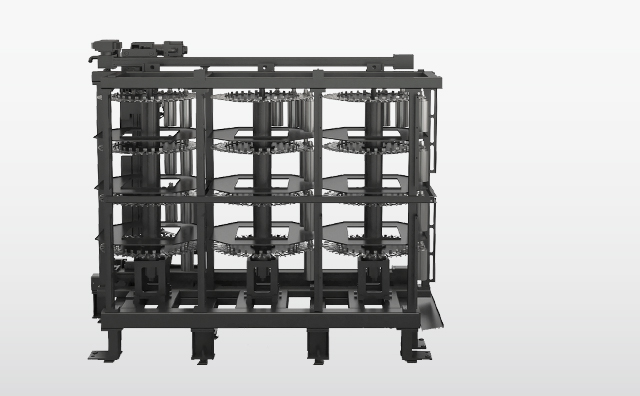

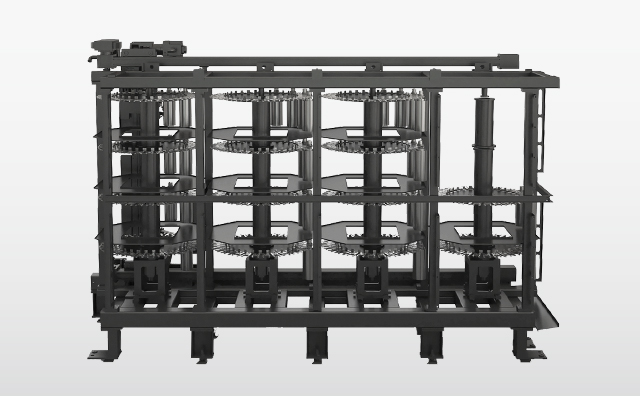

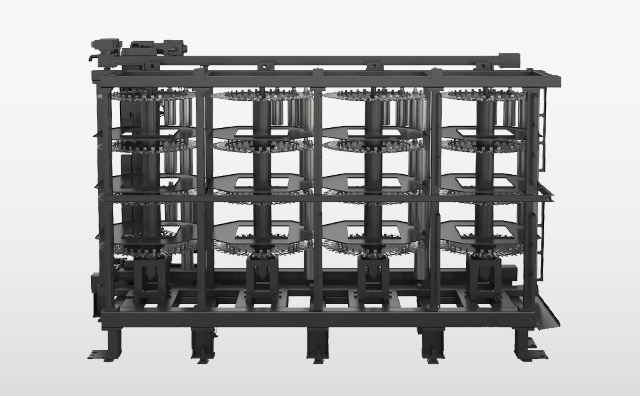

Multiple drum tool magazine

Multiple drum tool magazine automatically supplies tools to the tool magazine on the machine. It supplies up to 505 tools. With this system, operator can safely setup/remove tools and input tool data even during machining.

Space saving

We have pursued a more space-efficient tool magazine. By stacking drum magazines that can hold 30 tools, the system have minimized space expansion even when the number of tools is increased.

Compared to the rack-type, large-capacity tool magazine "Tool Hive," the floor space has been reduced by 35.6%.

Large-capacity, space-saving tool storage for the machining of a wide variety of small-lot parts

The number of magazines can be selected according to the number of tools required.

- image 1

- image 2

- image 3

- image 4

- image 5

- image 6

- image 6

Wide range of spindle variations

A wide range of spindles is available, from high-torque types suitable for heavy-duty cutting of difficult-to-cut materials, steel and castings, to high-speed machining spindles for aluminum, which are required for high-precision parts and aerospace components.

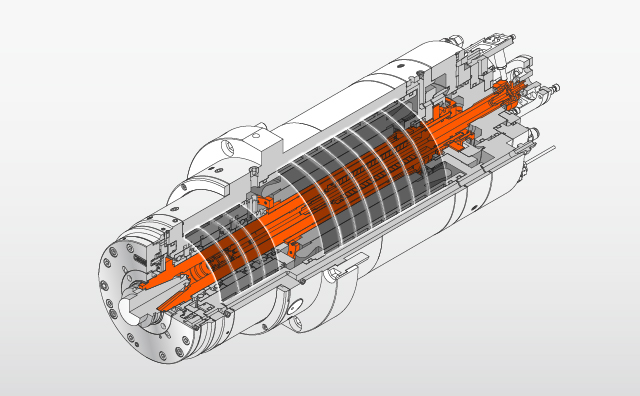

Built-in motor structure

The built-in motor structure reduces power loss and minimizes vibration at high-speed machining. This ensures exceptional surface and maximum tool life.

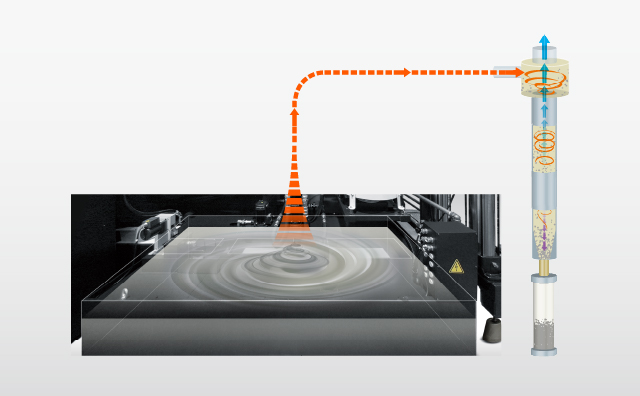

Spindle temperature control

Temperature-controlled cooling oil is circulated around the spindle bearings and headstock. It suppressed the thermal displacement of the spindle to prevent lower machining accuracy.

| Spindle speed : | Standard | High-torque* | High-speed* | |

|---|---|---|---|---|

| 12000 min-1 | 18000 min-1 | 25000 min-1 | 30000 min-1 | |

| Output (40% ED) | 22 kW (30 HP) | 35 kW (47 HP) | 23 kW (31 HP) | 23 kW (31 HP) |

| Max. torque (40% ED) | 71.6 N・m | 134 N・m | 22 N・m | 22 N・m |

| Tool shank | BT-40 / BBT-40* / HSK-A63* | BT-40 / BBT-40 / HSK-A63 | HSK-A63 | HSK-F63 |

- * Option

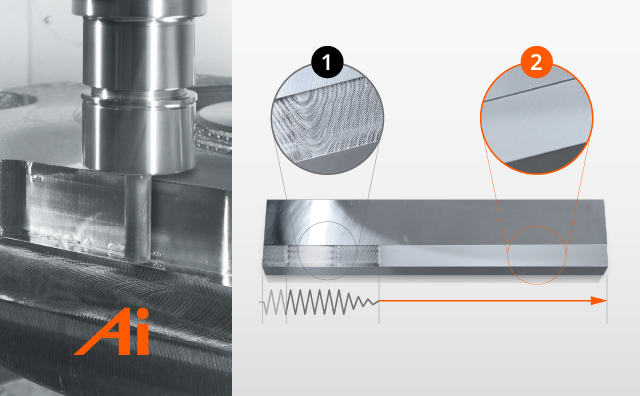

Smooth Ai Spindle*

If chatter vibration occurs during milling, the vibration sensor and AI adaptive control automatically change the machining conditions to suppress the chatter vibration. With the AI, even a less-skilled operator can make adjustments easily in a short time.

* Option

1: Chatter occurs

2: Chatter eliminated

Highly rigid structure for stable high-accuracy machining

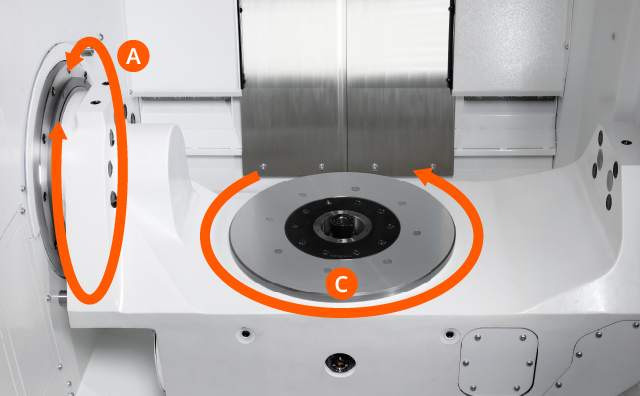

High rigidity table

This table adopts a structure supported by both ends with two points on the A-axis, enabling high rigidity and high-precision machining. The table can be indexed in 0.0001° increments in both the A- and C-axis, allowing complex multi-face and 5-axis machining.

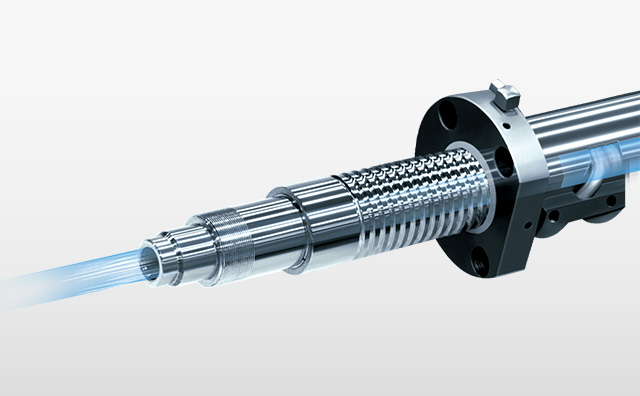

Ball screw core cooling

Temperature-controlled cooling oil circulates through the ball screw cores to reduce heat and thermal effects from the servo motor.

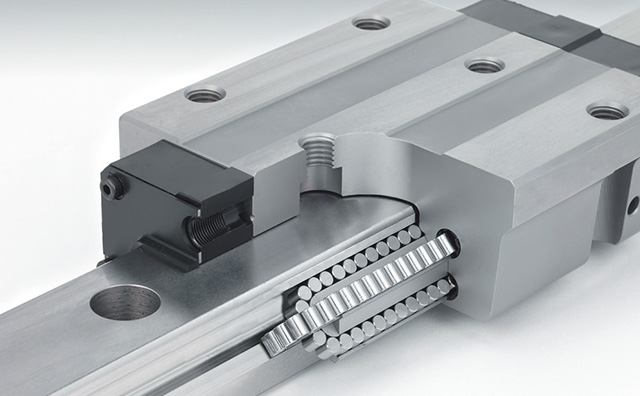

Linear roller guides

By using roller guides with excellent high speed and durability for the X-, Y-, and Z-axis, the machine has achieved high processing rigidity to maintain precision and minimized the need for maintenance.

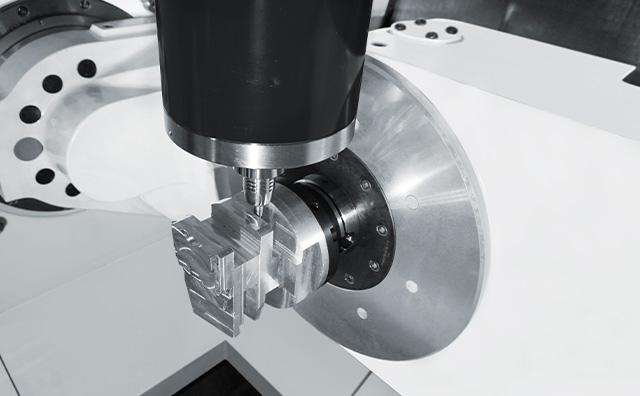

Compact spindle cartridge

The compact spindle and the work holder are clamped on the HSK-A100 interface. With minimum interference between the spindle and table, there is no need for any shimming when machining areas close to the table. The tool projection can be shortened, allowing for stable machining of workpieces with complex shapes.

Environmentally friendly

Energy Dashboard*

This application supports energy conservation by visualizing and analyzing power consumption.

* Option

Energy consumption is displayed on the process home screen.

- Total energy consumption (of workpiece in operation)

- Current energy consumption

1: Graphic display linked to energy consumption

2: Energy consumption by workpiece

3: Converts energy consumption into CO2 emissions/electricity charges

Clean coolant System *

The large-capacity 1100 L cutting water tank has a coating that prevents chips from adhering to it, and is designed to constantly create a vortex inside the tank using a water jet. By adopting this system, chips are guided to the filtration device together with the coolant, and more than 98% of particles larger than 10 μm are removed by a special cyclone filter.

In addition, the clean coolant system itself is maintenance-free, significantly reducing the time required to clean filters and tanks.

- * Included in optional coolant package.