| Max. cutting size (round) | Φ406 mm |

| Max. cutting size (square) | 305 mm × 305 mm |

| Max. workpiece length (loading) | 8080 mm |

| Laser power | 4.0 kW |

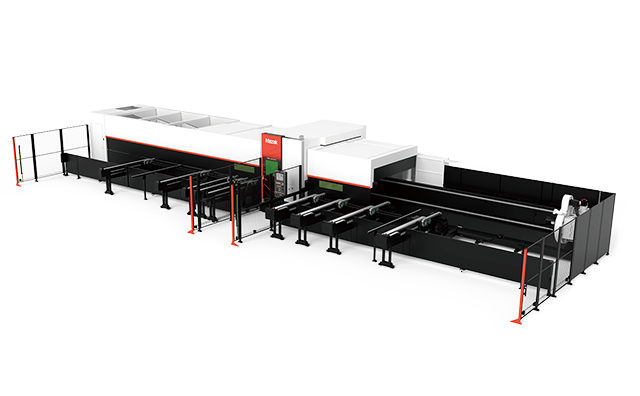

Laser Processing Machines

FG

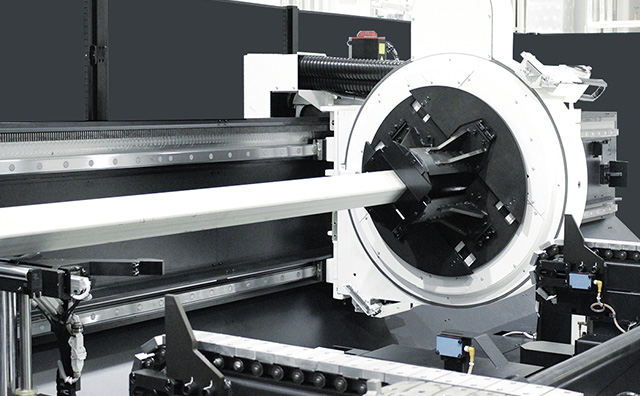

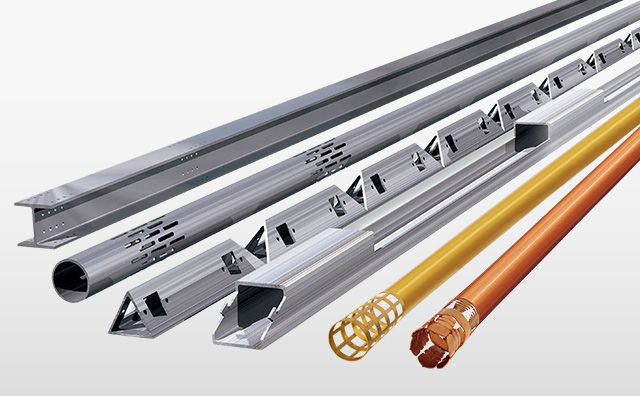

- Continuous automatic machining of long pipes and structural materials completes in one machine

- 3D laser head cuts and joints complex shapes with high-accuracy

- High-speed cutting by energy-efficient fiber laser

- MAZAK FX CNC control

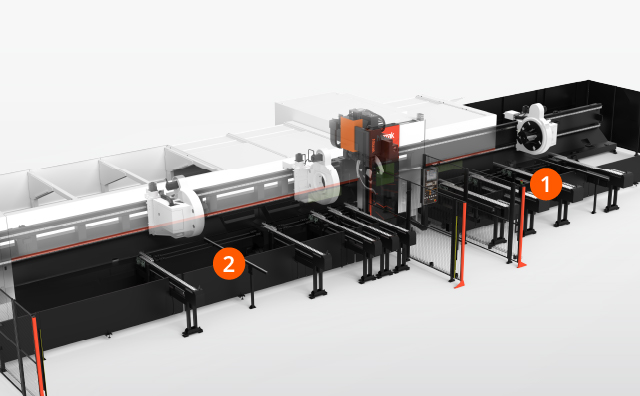

All cutting process in one machine

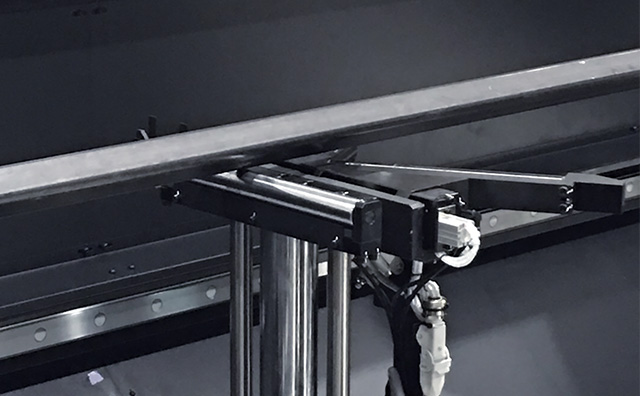

Automatic loading of materials and unloading of finished parts

- 1: |Automated loading of long materials from loading station

- 2: |Automated unloading of finished parts from unloading station

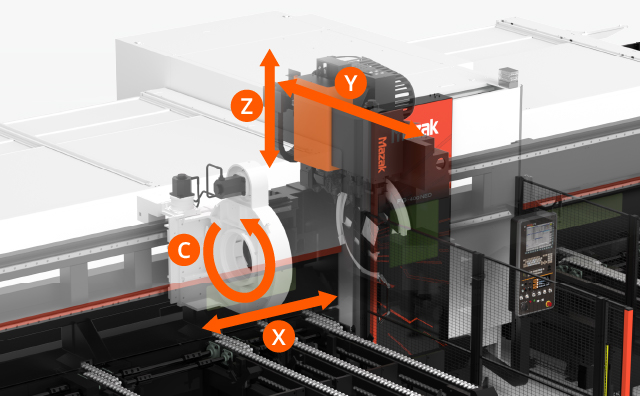

High-speed feedrate drastically reduces processing time

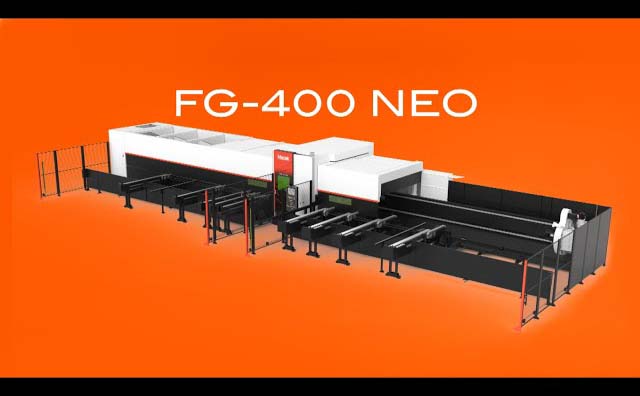

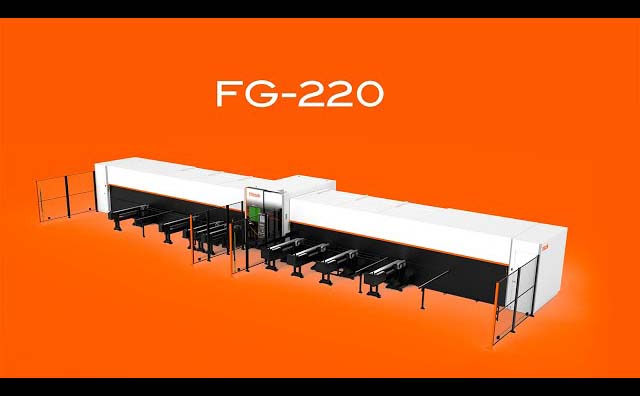

| FG-400 NEO | FG-220 | |

|---|---|---|

| X-axis | 60 m/min | 100 m/min |

| Y-axis | 36 m/min | 36 m/min |

| Z-axis | 30 m/min | 30 m/min |

| C-axis | 17400 deg/min | 20000 deg/min |

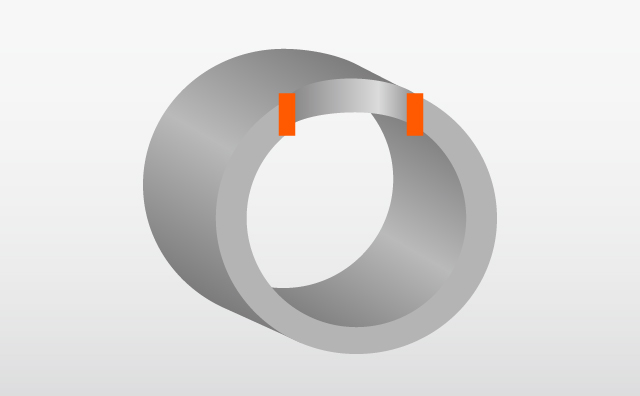

High-accuracy cutting while minimizing vibration

Four chucks move and rotate simultaneously to prevent material distortion. Various supporters suppress vibration and provide high-accuracy cutting.

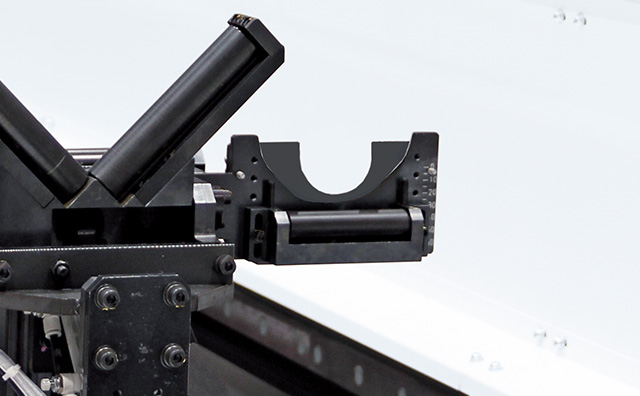

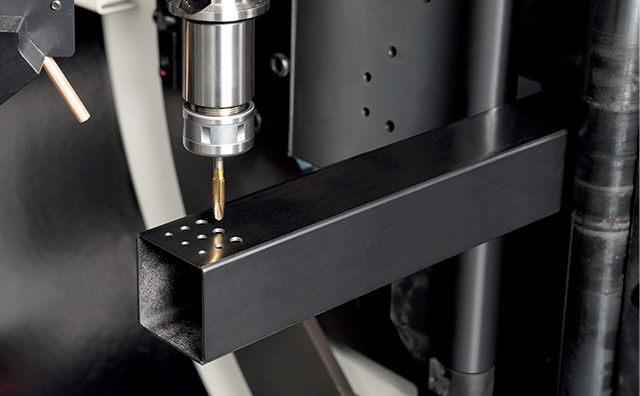

Tapping of long materials by the same machine

Optional tapping is added by attaching tapping unit. FG-400 NEO can accommodate up to M16 and FG-220 up to M12.

Advantages of process integration

All processes from materials to finished products, including transportation, cutting, bevel cutting, drilling, tapping, and punching, are completed on a single machine. Streamlining production processing and performance, our laser machines offer a wide range of benefits including a reduction in machine setup, production lead time, in-process inventory, the number of machines, fixtures, operators, floor space and higher precision.

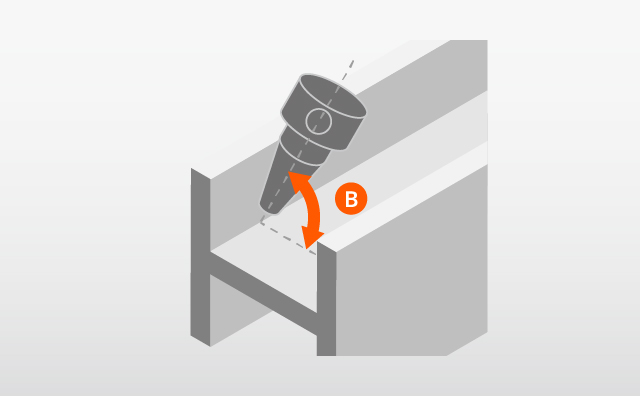

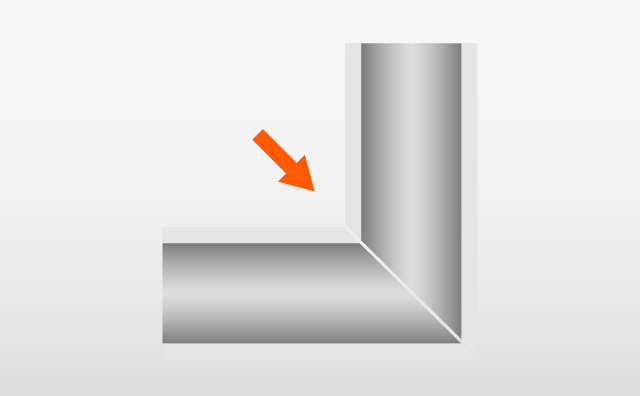

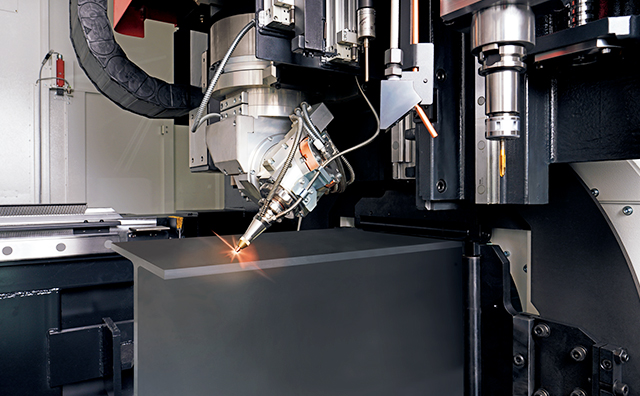

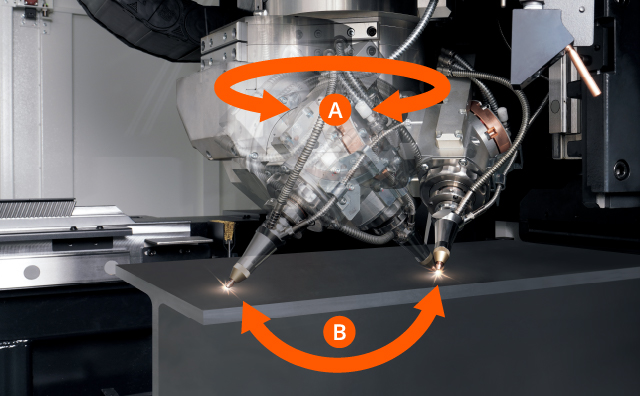

High-accuracy cutting by 3D laser head

Cut and joint broader range of materials and complex shape

The 3D laser head processes materials from various angles and directions. L, H, I-beam and channel can be processed as well as round and square pipe materials.

Protection torch

In the unlikely event of the torch striking the material, damage can be minimized as the torch itself tilts.

Higher efficiency with high-quality fiber laser

The advanced technology of the fiber laser provides higher productivity and higher efficiency

Capable of processing a variety of materials, including highly reflective materials

Fiber laser is capable of high-speed cutting of mild steel, which is difficult to process with CO2 laser cutting machines. It stably cut even highly reflective materials such as aluminum, copper, and brass.

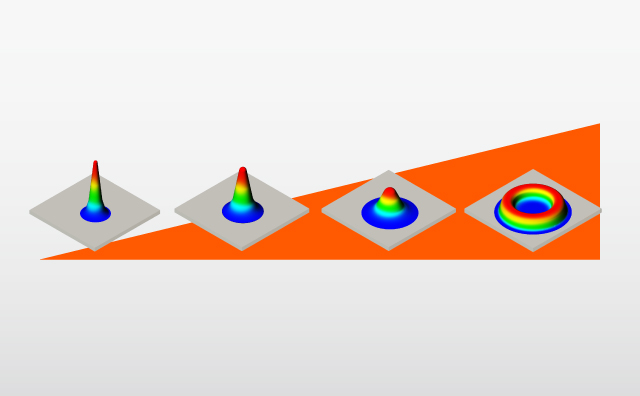

Beam Diameter Control function / Variable Beam Mode function*

Beam shaping technology automatically adjusts the beam diameter according to the material and thickness, and controls where the power density of the laser beam is concentrated. Together, these two functions improve the speed and quality of cutting a wide range of materials.

- * |Only available on FG-400 NEO

CNC system for 3D laser MAZAK FX

This advanced CNC system controls a total of 32 axes, including the loader/unloader of the 3D laser processing machine.

Reference Video

FG-400 NEO

FG-220

| Max. cutting size (round) | Φ220 mm |

| Max. cutting size (square) | 152 mm × 152 mm |

| Max. workpiece length (loading) | 8150 mm |

| Laser power | 4.0 kW |